Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 42

-

26th March 2018, 10:32 PM #1

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2009

- Location

- melb

- Posts

- 1,125

Flattening a slab and routing groove

Flattening a slab and routing groove

So as many of you guys have helped me with my current project - a waterfall edged coffee table, I am planning next project!

I have a slab of southern mahogany and wish to make a river art square - like this:

river art square / Greg Klassen

The slab is pretty flat but would like to know what is the best router trip if I needed to flatten it.

Also, what tip should I use to do the groove which the glass sits in - I suppose it will be a flush trip bit, but is there a special/specific type which would be best?

Lastly, if I wanted to make a wide area for the glass to sit in, one which is wider than the base of the router, how do I keep it flat?

Eg like the first pic in this link

10' black walnut river dining table / Greg Klassen

-

26th March 2018 10:32 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

27th March 2018, 03:28 AM #2

GOLD MEMBER

GOLD MEMBER

- Join Date

- Apr 2013

- Location

- Sydney

- Posts

- 1,557

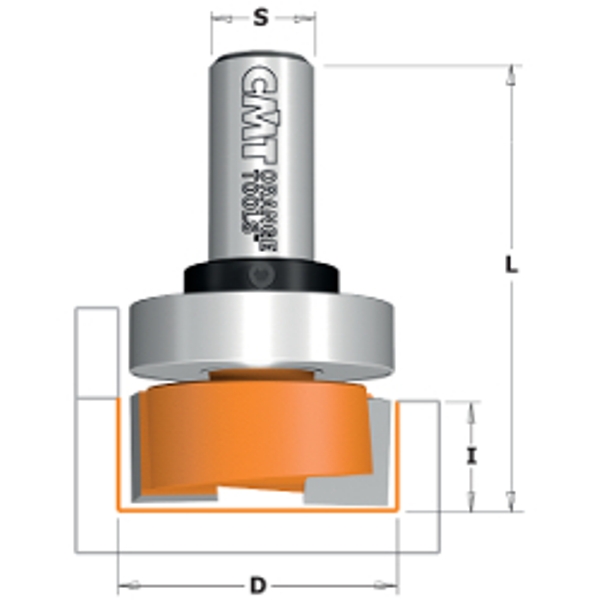

If it were me, I would make an MDF template of the shape ie following the contour of the river, but not as jagged, slow long curves but still enough to get the effect. I'd use a broad based rebate cutter something similar to this

an use the router freehand against the template. there are a few bearing-less rebate cutters out there and the wider the bit the better the lip for the glass to sit on.

hope this helps and was what you were asking.

-

27th March 2018, 05:07 AM #3

I suggest a router sled -- I'm sure there are examples and build instructions on this site. Just be sure that your work surface is flat, and you wedge the slab so it doesn't rock while you are flattening it.

also be sure that your slab is fully dry

I suggest that you make a template using either hardboard or 6 mm MDF. The curves on the template need to approximate the curve you are following and be smooth. Then use a top bearing rebate or morticing bit.

Only because I have downloaded a copy of the complete CMT catalog, the stock number of suggested bits would be

Morticing bits

801.190.11B (1/4" shank, 19mm dia, 19mm cutting depth),

801.818.11B (1/2" shank, 31.7mm dia, 5.7mm depth),

801.817.11B (1/2" shank, 31.7mm dia, 12.7 mm depth)

Dado and planer bit

852.001.11B -- 1/4" shank, 19mm dia, 9.5mm cutting depth

852.501.11B -- 1/2" shank, 19mm dia, 9.5mm cutting depth

852.502.11B -- 1/2" shank, 25,4mm dia, 9.5mm cutting depth

852.503.11B -- 1/2" shank, 31,7mm dia, 15,8mm cutting depth

852.504.11B -- 1/2" shank, 38,1mm dia, 15,8mm cutting depth

my suggestion is that you attach your router to a false base plate that is big enough to span the entire gap with length to spare.Last edited by ian; 27th March 2018 at 05:17 AM. Reason: added pics and edited catalog numbers

regards from Alberta, Canada

ian

-

27th March 2018, 10:21 AM #4

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2009

- Location

- melb

- Posts

- 1,125

Thanks guys. What brand of router bit should I get? Would like quality/clean cuts. I see the Amanatec has carbide bit which can be rotated when blunt? (like spiral cutter head of planner?)

-

27th March 2018, 11:09 AM #5

This test by Canadian Woodworking Magazine might help https://www.canadianwoodworking.com/...bit-comparison

Big caveat.

with a specialty bit like you will likely use for the rebate, you are very unlikely to cut anywhere near the equivalent of 320' (105 m) of MDF. This means that a bit that is good out of the box is likely to still be sharp years later.

Also, the Canadian test didn't include Australia's Carb-I-tool bits which are every bit as good as US or European made bits.regards from Alberta, Canada

ian

-

27th March 2018, 01:24 PM #6

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2009

- Location

- melb

- Posts

- 1,125

Thanks Ian. I'm downloading the carbitool catalog now. I see on that canadian woodworking site that CMT kinda sucks so I will avoid them. Where would one buy Freud? I might look through that catalog too. Is there anywhere else other than total tools to buy carbitool? I see that there head office is SE Melb, close to me.

Im also thinking about how I will attach the glass to the timber. Having a bit of an undercut for mechanical retention seems like a good idea, and I could probably do it with a dovetail bit with a bearing on top? On pg 13 what do you guys think about the "T cut" or the "gifkins" bit?

CARB-I-TOOL - Router Bit and Accessories Catalogue - NOVEMBER 2015

That would mean I will need to use 2 bits, which might mean it will be difficult to get a flat surface after routing? Does it seem too risky?

What are people's thoughts on type of glue I should use for glass and to timber? just an epoxy? Any thoughts on how to do it so its not so visible? Another option might be silicon - since its flexible it can account for wood movement?

-

27th March 2018, 02:37 PM #7

the glue question was discussed in a recent thread

I would advise against using a dovetail bit to undercut the top in an attempt to retain the glass.

the appropriate bit would be a slot cutter, followed by the rebate cutter -- but I note the piece you are emulating doesn't appear to have an undercut, and the table definitely is not undercut.

Again, only because I have a downloaded copy of the CMT catalog which makes searching much easier, the sort of bit I'm thinking of is item number 823.332.11B -- 1/2" shank, 47.6 mm dia, 3.2 mm wide slot.

I think you are going to need at least two bits.

A surface planer bit for the flattening and a either a bearing guided rebate or dado bit, or a similar bit guided by a copy ring.

BTW, what make and model of router do you have?regards from Alberta, Canada

ian

-

27th March 2018, 03:28 PM #8

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

Just my two cents worth: If you have some scraps or even other good pieces of the timber you are using, do some test cuts to

judge the right feed rate for the bit. Be a shame to ruin good timber.

-

27th March 2018, 05:20 PM #9

GOLD MEMBER

GOLD MEMBER

- Join Date

- Apr 2013

- Location

- Sydney

- Posts

- 1,557

I would avoid a slot or undercut, as the timber can and may move with the change in humidity etc, if the glass is trapped, it will don1 of 2 things, 1. The glass will shatter or crack, and 2. If u used toughened glass then it may not crack but split the wood along the top of the slot, which you don't want.

just some food for thought. I'd recommend exactly as it was shown, solid base with the 2 sides of the river secured fast, then just lay the glass in the the river. It'll also make cleaning easier!!

-

27th March 2018, 09:40 PM #10

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2009

- Location

- melb

- Posts

- 1,125

Thanks. I dont have the exact model but its a plunge router and made by Makita. Its an older router. If its no good I'll get a new one. I notice there arent many options for routers - Festool, Makita and Bosch? Are other ones worth looking at?

Ill deff practice first!

Im not actually make a table

-

28th March 2018, 02:39 AM #11

although I suggested a slot cutting bit if you want to create an undercut to retain the glass, I've subsequently had a good look at the photos in the link you posted in post #1. I'm sure I can see the edge of the glass in each photo, meaning that the originals are not undercut.

as Fumbler advises, best to stay away from a mechanical connectionregards from Alberta, Canada

ian

-

28th March 2018, 03:17 AM #12

GOLD MEMBER

GOLD MEMBER

- Join Date

- Apr 2013

- Location

- Sydney

- Posts

- 1,557

So, if your not making a table, or table top, what are you making?

with all said before maybe you can route the retainer groove a few mm wider than the glass, then use clear silicone along the edge wall of the cavity to retain the glass, and with the additional space any warping due to humidity may not spilt either the wood or the glass.

out of curiosity, how big are we talking here slab wise?

-

28th March 2018, 04:37 AM #13

qwertyu wants to make something like this

river art square / Greg Klassen

I'm sure the glue issue has been answered recentlyregards from Alberta, Canada

ian

-

28th March 2018, 06:17 AM #14

-

28th March 2018, 08:01 PM #15

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2009

- Location

- melb

- Posts

- 1,125

Thanks guys.

Had a look at the Makita router - it is the 3600BR. 1/2" 1500W unit. Its pretty old/beat up but still works. The plunging mechanism isn't so smooth but I dont think I will be doing any plunging.

I think for router bits I will go with the carbitool surface planer

https://www.google.com.au/search?q=c...EqnM8gem6r7wCA

and the carbitool inverted flush

https://www.totaltools.com.au/42708-...4-shank-t8216b

You guys think they will be suitable? is 2 cutter heads for the inverted flush enough (ie will it be a rough cut?)

Only issue is that the inverted flush has 1/4" shank - I dont think I have an adapter. I also have a makita palm router - are they usually 1/4"? (dont have the model number right now)

In terms of glue - I looked at that thread - clear epoxy seems to be the suggestion. you guys think I should just glue the edge of the glass to the wood (glass might be 6mm think)? Or the entire surface which is sitting to the glass (more risk of air bubbles)

The slab is almost 2.Xm long. But I dont plan on using the entire slab, just a portion to get a triptych.

Similar Threads

-

Need help with routing a groove.

By Jaff in forum ROUTING FORUMReplies: 6Last Post: 8th January 2014, 09:04 PM -

deep groove

By danielr in forum WOODWORK - GENERALReplies: 7Last Post: 21st August 2013, 11:23 AM -

Hanplaning groove

By quackos in forum HAND TOOLS - UNPOWEREDReplies: 4Last Post: 14th February 2008, 07:53 AM -

V Tongue and groove bit

By Stevenp in forum ROUTING FORUMReplies: 5Last Post: 25th July 2007, 10:30 PM -

Flattening a slab top

By Biggles in forum WOODWORK - GENERALReplies: 3Last Post: 12th August 2002, 07:45 AM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote