Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 22

-

3rd March 2016, 11:33 AM #1

Intermediate Member

Intermediate Member

- Join Date

- Dec 2012

- Location

- Sydney

- Posts

- 27

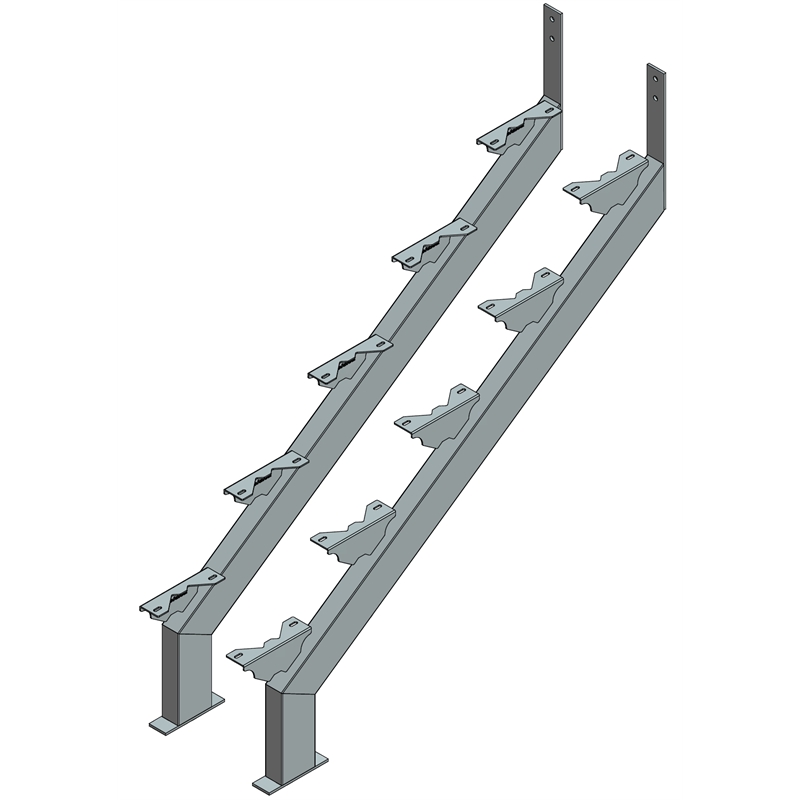

Hidden fixing of timber stair tread to metal stringer?

Hidden fixing of timber stair tread to metal stringer?

Does anyone have any ideas on how something like this is achieved, where there are no visible fixings between the timber tread and metal stringer? My design authority has asked if this would be possible on our new stairs

If not using standard stair bracket would it need to go through a structural engineer?

Thanks

stairs.jpg

-

3rd March 2016 11:33 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

3rd March 2016, 12:59 PM #2

GOLD MEMBER

GOLD MEMBER

- Join Date

- Aug 2011

- Location

- bilpin

- Posts

- 3,559

Metal tang fabricated on stringer and slot on end of tread, usually screwed from underneath

and screw holes filled.

-

3rd March 2016, 02:20 PM #3

Intermediate Member

Intermediate Member

- Join Date

- Dec 2012

- Location

- Sydney

- Posts

- 27

-

3rd March 2016, 02:49 PM #4

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2011

- Location

- Murray Bridge SA

- Posts

- 3,339

That's correct, when you cut the slot, make it blind, so you won't see the slot from the front, and you'll also need to chamfer the sides of the slot to allow for the welds top and bottom.

KrynTo grow old is mandatory, growing up is optional.

-

3rd March 2016, 03:23 PM #5

Intermediate Member

Intermediate Member

- Join Date

- Dec 2012

- Location

- Sydney

- Posts

- 27

Thanks, I guess there is a bit of a trade off between how deep the slot can be routed vs the width of slot vs the thickness of tread material left to bear on!

-

3rd March 2016, 04:58 PM #6

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- May 2011

- Location

- gippsland

- Posts

- 815

I would keep the slot in the bottom third, if not as low as possible. to allow for downward loads.

-

3rd March 2016, 05:07 PM #7

Intermediate Member

Intermediate Member

- Join Date

- Dec 2012

- Location

- Sydney

- Posts

- 27

Would it be an option to drill holes in the steel and use a couple of M10 or M12 coach screws or would this be too insecure going into the end grain of the timber?

-

3rd March 2016, 05:35 PM #8

Going by that image there is a gap between the stringer and the thread. You can see the shadow of the bolts/fitting etc if you look closely

Cheers

DJ

-

4th March 2016, 01:17 PM #9

-

4th March 2016, 03:56 PM #10

GOLD MEMBER

GOLD MEMBER

- Join Date

- Aug 2011

- Location

- bilpin

- Posts

- 3,559

Stair treads should be fully supported at ends. So that counts bolts out. Minimum trench for treads in timber is 12mm, so steel tangs would have to be at least that. I would use 50mm as that would allow for up screwing from underside of treads well in from ends. If necessary, slots in treads can be blind at the front only, to allow treads to be slipped in from the rear. This has the advantage of locating stringers one at a time and then fitting the treads one by one. Much easier than trying to lift the whole caboodle into position.

I realize this does not alpply to your hanging staircase, but you may be glad of it when you replace it with something more sensible

-

5th March 2016, 01:24 AM #11

Intermediate Member

Intermediate Member

- Join Date

- Dec 2012

- Location

- Sydney

- Posts

- 27

yes this could be a problem, suppose you have to design for the worst case!

yes this could be a problem, suppose you have to design for the worst case!

The only downside I see with cutting a slot is that after you cut the slot the thickness of the timber bearing on the metal will be reduced, it might mean you would need to use a tread much thicker than required by the standard.

Have you had a bad experience with hanging stairs, maybe I can convince you once it's all done This would actually be for the wall side of my hanging stairs, only one side would be hanging, like pic below.

This would actually be for the wall side of my hanging stairs, only one side would be hanging, like pic below.

godzilla.jpg

-

5th March 2016, 08:54 AM #12

Senior Member

Senior Member

- Join Date

- Dec 2012

- Location

- emerald

- Posts

- 162

-

5th March 2016, 10:10 AM #13

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2012

- Location

- SE Melb

- Age

- 64

- Posts

- 1,278

-

5th March 2016, 04:43 PM #14

Intermediate Member

Intermediate Member

- Join Date

- Dec 2012

- Location

- Sydney

- Posts

- 27

-

5th March 2016, 05:33 PM #15

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2012

- Location

- SE Melb

- Age

- 64

- Posts

- 1,278

I don't think it's a normal practice to cut tenons in treads at all. The only reason to do this was to create a "floating" stair case look that you asked for . I would have thought you cut away as little as possible to create that look, say 5mm right around.

If the steel stringer is hidden behind plaster, why not get this type of stringers, on one side of course.

Similar Threads

-

stair stringer using wedges

By Hilton B in forum WOODWORK - GENERALReplies: 1Last Post: 26th January 2010, 07:39 PM -

g'day - stair stringer advice

By cycledude in forum G'day mate - THE WELCOME WAGON -Introduce yourselfReplies: 7Last Post: 6th September 2009, 10:23 PM -

Stair stringer thickness

By silverman in forum WOODWORK - GENERALReplies: 1Last Post: 5th February 2009, 11:36 PM

Reply With Quote

Reply With Quote