Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 8 of 8

Thread: Sharpening philosophy

-

19th February 2008, 10:03 PM #1

Sharpening philosophy

Sharpening philosophy

This thread began on another forum. However, I thought the issue so important that I would reproduce the essence here.

Essence: Even the best jig needs to be adjusted. More to the point, sharpening/grinding is not a mindless activity.

In another thread on another forum, it was argued that the use of a honing guide encourages a thoughtless attitude. My response was that sharpening is not mindless just because one might use a honing guide. The more experienced one becomes in this area, the more one will tune in to issues - such as the need to hone the back of the blade. Tuning in remains a factor whether one hones with a guide or freehand.

The most common adjustement query when using a guide or machine is when the bevel is being ground at a skew.

Since getting a Tormek, it has occurred to me that one of the "weaknesses" of the LV Honing guide Mk II, this being that the double screw system, is actually a strength.

I was considering buying the upgraded blade holder for my Tormek 2006. This one clamps the blade differently and, in the new method, will not cause the blade to skew. I now see this as a weakness in the design. It places great emphasis on the wheel to be aligned perfectly with the tool bar. On the old model (mine) one can quickly and easily adjust for a skew being ground by adding more tension to the screw on the holddown on the side of the blade with less grind (or decrease the tension on the side of the blade with more skew). The same situation exists with the Mk II honing guide.

The potential danger with a jig or guide is that one leaves the "work" to it. Jigs where there are no adjustments make it difficult, if not impossible, to alter a setting. Settings need to be adjusted on the fly.

For example, if freehanding a blade, one adjusts pressure over the bevel to "level up" the wear. Similarly, this takes place with jigs/guides as well.

There is a mindset here that I feel may escape especially the novice, who expects the jig to do all the work, and that it is at fault if the product is not perfect.

When I mention the (several) machinery I own, the comments I receive from some indicate that they think I love sharpening, or I love machines, or both. I both dislike the intrusion of sharpening into the act of working wood, and I dislike most machines with a passion.

I recently bought the Tormek 2006. I have even more recently bought a 10" high speed bench grinder (uses a 10" white Norton 46 grit wheel). It scares the bejesus out of me!

Here are the two in my "garden" workshop:

Before getting the 10" machine I had a 6". (No comments about male menopause, children! ..... it is enough that my wife still refers to my Porsche 356 as the Menoporsche! ) The reason for upping the wheel size was that I might start a grind on the bench grinder (if there was a lot of steel to remove) and finish on the Tormek. This is not something that most will do, but I do have an interest in making blades along with making planes, so it is not just about working wood. Anyway, the two machines are intended to compliment each other.

Now let's not forget that I also own, and use, a 6" wide belt sander...

...AND there are the honing guides (e.g. LV Honing Guide Mk II, plus a few others, such as the Sharp Skate - which has a brilliant concept, one quite appropriate to this topic).

Gad, Derek, who could blame anyone thinking you were nuts about sharpening!

OK, let's stand back and examine what this is all about.

Sharpening is not about machines and jigs. Sharpening should be a quick, but careful activity directed at creating a sharp edge for the purposes of working wood. No more than this. Sharpening is not an end to itself. Sharpening should not involve endless obsessing over edges. Did I mention that I dislike sharpening? That does not mean that I stop trying to understand it.

I complicate my world by having different tools, many different tools. Well, part of my interest in woodworking is the history and design of woodworking tools. Probably about equal to building furniture. The trouble is that different tools require different strategies, especially if you want to be efficient and get it done quickly but correctly.

Having both bevel up (BU) and bevel down (BD) planes, for example, introduces opposing sharpening strategies.

My preference is to hone BD blades freehand on waterstones. To facilitate this, I want a hollow grind. The exact bevel angle is not important - I choose it on the basis of the steel and the wood - because the cutting angle is taken from the angle of the bed, not the bevel.

The problem with a high speed bench grinder is the heat generated. I am pretty good at freehand grinding, and cannot recall when I last blued a blade, but there are limitations that remain nonetheless. The primary one is that it is a no-no to grind to the edge of the blade as this will overheat it. Consequently, one really should stop short a few mm away. The resulting "microbevel" that is honed is quite large, usually ending up about 3 (or more) mm wide.

The reason I bought the Tormek was that I could grind to the very edge of the bevel. The blade is cooled by the water and there is no danger of losing temper. As a result, I can now hone a true microbevel, one that is a fraction of a mm wide. The beauty of this is that it takes literally seconds to do freehand!

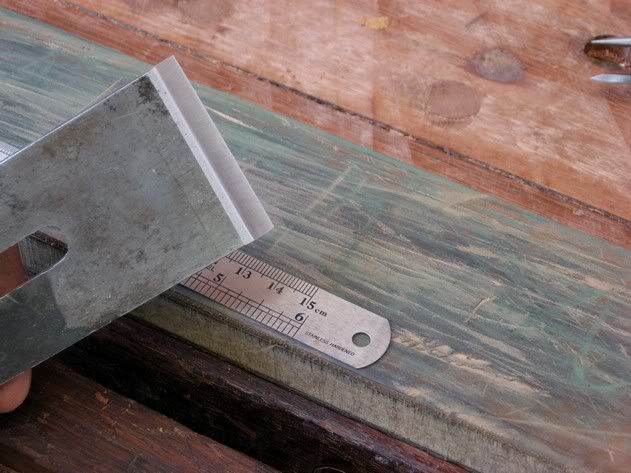

Here is a microbevel of the type I mention. Note that the iron is a tapered Matherson woodie. It is thick at the sharp end, and so I did not grind a hollow all the way back. The flat you see is from old, previous grindings (from old grinders, no doubt):

When it comes to BU blades, the angle at which they are ground does count. It is all important when one is planning hard, interlinked grain and wanting to prevent tearout.

I could use a hollow grind with these blades, but it is not efficient - too much steel to remove. It is far simpler to start with a lowish primary bevel (say 25 degrees) and add a microbevel of choice. The angle of this microbevel is important to get right, so I turn to using a honing guide. I consider that I am quite good at freehand control for most hollow grinds and flat grinds, but I am not good enough to do accurate and repeatable microbevels.

For a flat grind I use the beltsander. A belt of 80 grit will grind or re-establish a fast primary bevel. There is no need to go higher, but you can reduce the size of the subsequent microbevel if you go to 240 grit (i.e. smaller serrations). The beltsander does a fantastic job at this. It is as good at creating a flat grind as the bench grinder, et al are at creating a hollow grind.

The beltsander is also used to square up my Japanese chisels. They need a flat primary bevel. By contrast, my non-laminated chisels are hollow ground on the bench grinder. Both are then honed by hand on waterstones. I do not use microbevels on chisels, with the exception of the Oval Bolstered Mortice chisels. The reason is that it is hard to then run them on the bevel, per se, and it is also difficult to strop them (between sharpenings).

There are other strategies that one needs to keep in mind as one hones, in addition to the issues of skew that I mentioned at the start. One is what one does to maintain an edge between honings. This takes us to the topic of stropping. Now I do not plan to go into this here. The topic is NOT about sharpening - it is about your plan that lies BEHIND sharpening. It is about the thought you give to what you do - before you do it AND WHILE YOU DO IT!

As I stated earlier, sharpening should be quick and easy. I know that I have made it sound extremely complex here. Actually it is really simple. What is complex is the thought that lies behind the simple act.

Is anyone still awake!?

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

19th February 2008 10:03 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

19th February 2008, 10:19 PM #2

Thanks for sharing that Derek.

Cliff.

Cliff.

If you find a post of mine that is missing a pic that you'd like to see, let me know & I'll see if I can find a copy.

-

19th February 2008, 10:20 PM #3

Interesting thread Derek.

Like you, I see the preparation of edges as being very important to my woodwork however I don't do woodwork merely to dull my blades so I can have the pleasure of sharpening.

Seeking techniques so edges last longer is just as important to me as being able to quickly restore an edge that has become dull.- Wood Borer

-

20th February 2008, 06:27 AM #4

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

Sharpening

Sharpening

Sharpening is the bane of my existence! Threads like this are most helpful. Thanks Derek.

-

20th February 2008, 07:32 AM #5

I agree with almost everything you have said Derek, and where I disagree, it is a question of emphasis only and so not worth bothering with, unless you want to have an argument

.

.

Sharpening is an unavoidable part of using metal tools on wood. The only problem I have with 'disliking' sharpening is that it is a bit like hating a part of your own body. It may be less well favoured, but it is still part of the whole.

It comes down to attitude and perspective. My performance with sharpening has improved since I adopted three principles:

- sharpen or hone or strop, as appropriate,any tool as soon as the edge goes off

- use the easiest method that is closest to hand to deal with the edge concerned

- think of the break as part of the job and use the time not just to sharpen the tool but also to think about how you are going to finish the step that you are working on and what the next step is.

Cheers

Jeremy

If it were done when 'tis done, then 'twere well it were done quickly

-

24th February 2008, 08:33 PM #6

Many thanks Derek. As usual, most informative and practical.

I have a setup similar to yours, in that I use a standard high speed bench grinder (200mm) in conjunction with a Tormek, and occasionally a linisher belt for flattening. I also use a Oneway grinding jig & accessories for lathe chisels and for general purpose chisels and plane blades. I have assembled myself a little sharpening station with the equipment all mounted on a cabinet on wheels, and have now got to the stage that I can sharpen virtually any chisel or blade in under a minute (unless its badly gapped) - including honing on an oil stone. I hone by hand (ie. by feel) on an aluminium oxide combination stone. I'm considering upgrading to the finer Shapston stones etc shortly

A question re the Tormek. Do you use the leather stropping wheel? I have tried it in conjunction with the honing paste supplied, but can't really say that I'm fully impressed with the results. Where do you use the leather strop within the sharpening process?

Regads. WayneDon't Just Do It.... Do It HardenFast!!

Regards - Wayne

-

24th February 2008, 09:11 PM #7

Hi Wayne

Sounds like you have a thought-out and comprehensive system ... except for the stones!

I have tried the Tormek strop. I am actually quite impressed with the limited (freehand) use I have made of it. I have this idea - when the new workshop is built (after the builder leave) - to have a dedicated sharpening corner (with the grinders and belt sander, stones, etc). The Tormek will either be on a carasell so that I can flip it around to use the strop, or I will leave it reversed (as I presently use it) and add a separate on-off switch.

For a strop I prefer hard leather on hardwood.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

6th April 2008, 11:47 PM #8

Once again, a very good read Derek. I would like to second the comments you had about the the new tormek blade holder. It is true that unless you have the stone perfectly true even if your tool is perfectly aligned, you will get a skew grind.

Another important issue that I have noticed is that although this new guide has the self aligning ridge on the side, for a lot of tools you cannot rely on this to get a straight grind as often the sides of the blade are not parallel to the face of the blade. This is true for many of the older chisels, particularly the ones that have had a hard life!

One last comment, although I do not by any means enjoy the process of sharpening, it is certainly a good feeling when the blade feels sharp at the end of the process.

regards

MariosYou can never have enough planes, that is why Mr Stanley invented the 1/2s

Similar Threads

-

Philosophy

By Shedhand in forum WOODIES JOKESReplies: 5Last Post: 25th January 2007, 10:50 PM -

Sharpening 101

By silentC in forum SHARPENINGReplies: 70Last Post: 7th February 2006, 09:50 PM -

Philosophy for 2006

By rodm in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 0Last Post: 4th January 2006, 03:39 PM -

Philosophy

By Bob Willson in forum WOODIES JOKESReplies: 11Last Post: 7th July 2004, 06:53 PM -

A good philosophy

By Eastie in forum WOODIES JOKESReplies: 2Last Post: 12th January 2003, 06:30 AM

Reply With Quote

Reply With Quote