Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 8 of 8

-

23rd April 2017, 03:52 PM #1

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2012

- Location

- SE Melb

- Age

- 64

- Posts

- 1,277

Low cost home made marking knife honing guide

Low cost home made marking knife honing guide

I have one of these marking knives s-l1600.jpg

I've been honing it free hand since the blade is quite short and there isn't a honing guide I have that would be useful.

but after a year or two, the shape of the bevel was looking horrible.

I want a honing guide of some sort. So after trying many different ideas, some ok but none that popped out as an excellent idea, I came up with using rare earth magnets as my guide. I hit pay dirt.

It is an extremely simple idea. I use two 50 x 10 x 3 mm rare earth magnets that act as a clamp guide.

Just slide it until it's the right distance from the edge to get the bevel angle that you want.

I put a bit of electrical tape to protect the magnets from being damaged from rubbing against my water stones.

I can hone away at the right angle. I can still practice those locked elbows and looking at the water film displaced as a guide to getting the right angle. But the guide stops things going astray every now and then. I think it's a nice idea for others who want a cheap and usable solution.

Comments welcome.

20170423_120450.jpg20170423_120457.jpg

-

23rd April 2017 03:52 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

25th April 2017, 08:21 AM #2

GOLD MEMBER

GOLD MEMBER

- Join Date

- Apr 2011

- Location

- McBride BC Canada

- Posts

- 3,543

Excellent trick.

I have several pairs of 12mm skews and a Pfeil 1S/25e carving skew. I've begun to wonder

just what condition the so-called 20 degree bevels are in.

Where did you buy the magnets?

-

25th April 2017, 09:21 AM #3

Good idea. I tried this Paul Sellers jig once before but it didn't work out for me. I've been meaning to give it another try and I suppose it could also be reconfigured to work with an end cutting blade like that knife.

Franklin

-

25th April 2017, 11:01 AM #4

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2012

- Location

- SE Melb

- Age

- 64

- Posts

- 1,277

The bevel were getting rounded and also the surface was sitting on multiple planes, each ever so slightly different than the other, so I suspect the edge wasn't exactly a single line, but multiple edges overlapping each other over time. Now the bevel is like that when it was new. I have also lowered the bevel angle to 15 degrees, for honing to 20 later on.

I bought the magnets from a hardware store in melbourne, they were 2 bux each.

-

25th April 2017, 11:08 AM #5

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2012

- Location

- SE Melb

- Age

- 64

- Posts

- 1,277

You can buy the same magnets on ebay for a buck each. 10/50/100 N35 Strong Round Block Disc Magnets Rare Earth Neodymium Magnet 10x6mm | eBay. They are extremely strong and with two clamping on the blade it didn't move at all during the session. Also I discovered that duct tape is a better alternative to electrical tape. It just sticks so much better.

Fuzz, thanks for reminding me about that Paul Seller's jig. Now I remember I read it quite a while ago.

-

25th April 2017, 12:33 PM #6

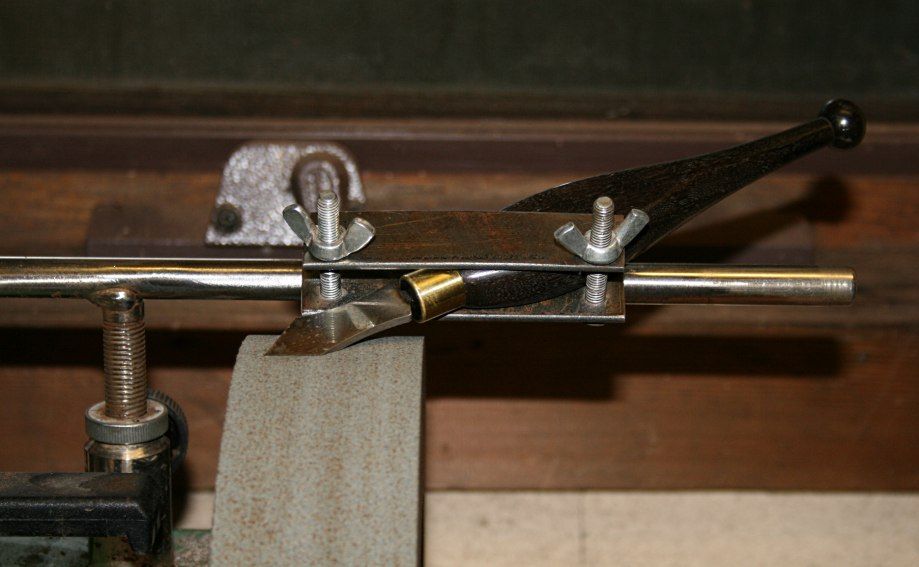

I use a similar jig to hollow grind the bevels of my knives ...

The hollow grind makes it very easy to freehand sharpen.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

25th April 2017, 12:54 PM #7

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2012

- Location

- SE Melb

- Age

- 64

- Posts

- 1,277

How is your jig threaded through the universal support arm, Derek?

-

25th April 2017, 02:04 PM #8

It is not threaded. No need - I used an L-section. This is held on with finger pressure. It is very simple to make one of these, and you can have several.

Here it is on a belt sander (taken a dozen or so years ago - very reliable blade holder) ...

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

Home Made Jessem Stock Guide Clone for New Harvey HW110LGE 30 Table Saw

By DomAU in forum TABLE SAWS & COMBINATIONSReplies: 2Last Post: 23rd January 2016, 06:19 PM -

Home made clamp guide plans

By Tiger in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 13Last Post: 1st November 2007, 08:24 PM -

Honing Guide

By Chris Parks in forum WOODWORK - GENERALReplies: 2Last Post: 9th August 2007, 05:06 PM -

Honing guide

By sinjin1111 in forum SHARPENINGReplies: 4Last Post: 8th May 2005, 01:50 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote