Needs Pictures: 0

Needs Pictures: 0

Results 1 to 15 of 17

-

11th February 2016, 10:00 PM #1

Novice

Novice

- Join Date

- Feb 2016

- Location

- West of Sydney

- Age

- 47

- Posts

- 16

Universal Drill Press Stand... yes or no?

Universal Drill Press Stand... yes or no?

Hello all,

Hoping to get some advice concerning the product named in the title of the thread. The idea is that instead of buying a drill press, you pay less money and probably take up less of your working area by getting a universal stand and loading it with a drill you already own. Sounds great, but I'm wondering if it really is all that simple. I'm generally ok with fiddling and working on something a while longer if it will save me some $$s, but there are limits to how much fiddling can be tolerated before one is checking the size of the rainy day fund and looking up prices of better equipment.

For anyone who has used one of these, or know someone who has, would it be worth my while as a hobbyist who does a few projects a month, or are they too much of a pain?

-

11th February 2016 10:00 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

12th February 2016, 12:44 AM #2

Novice

Novice

- Join Date

- Jan 2013

- Location

- Adelaide South Australia

- Posts

- 15

Drill press stand

Drill press stand

Hello I happen to have both a drill press and universal drill press stand ( given to me) and find that it is alright for small jobs. I had a spare drill in the workshop that I setup with it and had to make a lot of adjustments to it so that it would drill square to the job. They are certainly smaller than a drill press and once setup it works well for small jobs. Would I buy one probertly not. I much prefer the the strength and rigidity of a drill press.It really depends on what you want to use it for. I hope that this helps.

Shaun.

-

12th February 2016, 09:33 AM #3

Novice

Novice

- Join Date

- Feb 2016

- Location

- West of Sydney

- Age

- 47

- Posts

- 16

Thanks Shaun. I gather from what you are saying that the stand *might* work out if I'm willing to put in some time and effort to set it up firmly on a solid base, taking special care to get it square. I wouldn't want to be putting it away once it is setup, so it needs its own spot (difficult but not impossible, and probably still better than a proper drill press in terms of space use). The stuff I've been working on has all been small, and I've not been fussy enough to do anything beyond freehand. I think the last time I used a bit more than 3 or 4mm was when I installed some shelving a while ago. I will, however, be looking to make a bunch of dowel holes probably 8-12 mm in the near future, which is what has me thinking about drill presses.

-

12th February 2016, 10:40 AM #4

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,791

Drill presses are one of the most versatile and commonly used items in most workshops so they can usually claim their own space.

If space is an issue I would go for a small drill press as these take up about the same room as a universal stand and like you said you will use it so much you won'y be putting it away every time

The problem with the universal stands is they cannot take a lot of pressure so they end up bending and making crooked holes.

Certainly 12mm holes could be a concern

Drill press can be used for so much more than drilling holes and I'm sure you will find more uses for it.

FWIW SWMBO has a stand for her Dremel and a set of drills that are <2mm for her jewellery work, which I use sometimes - the stand is fine for this sort of work.

-

12th February 2016, 04:46 PM #5

there are two general versions of these sorts of stands, the

less than $40 version from Jay car and others and the $200 version marketed by Metabo

One or two forumites have the Metabo version and are happy campers.

But for the dollars involved (factoring a suitable drill) you are better off with a dedicated drill pressregards from Alberta, Canada

ian

-

12th February 2016, 05:37 PM #6

Woodworking mechanic

Woodworking mechanic

- Join Date

- Jan 2014

- Location

- Sydney Upper North Shore

- Posts

- 4,470

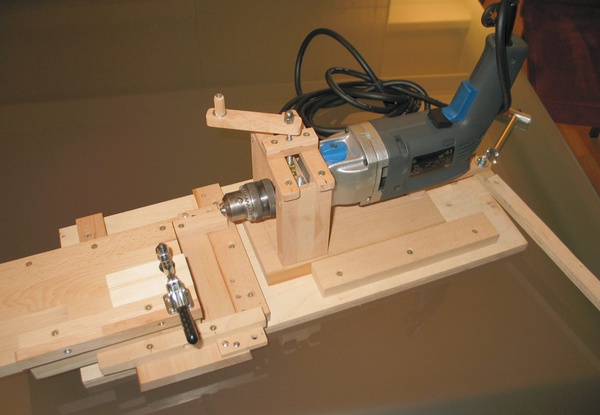

I bought a Record unit about 18 months ago as I needed it for a specific task. This is the unit

R9526 | DS19 Compact Drill Stand - Suits Power Drills | For Sale Sydney Brisbane Melbourne Perth | Buy Workshop Equipment & Machinery online at machineryhouse.com.au

This is how I set it up for the task - turned it backwards.

image.jpg

The unit is sturdy enough - no flexing, bending etc. but if you put too much pressure on it, it will slip where it tightens to the vertical shaft. The tendency is to tighten it more, but it is a casting so I was dubious about its strength

Still,with a sharp drill bit, it has no problems drilling up to 12mm in wood with a twist drill and 32mm with a spade bit.

The drill depth stop is a waste of time - keeps loosening even though I put a lock nut on it, due to the square cut pawl inside.

i still use it for many small drilling tasks as I don't have a drill press - I use the ones at work for heavy duty and accurate metal drilling

-

12th February 2016, 05:52 PM #7

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2007

- Location

- Sydney

- Posts

- 749

I have a universal one & a dedicated drill press - chalk & cheese. Suggest you save your money & buy a dedicated drill press unless you really need a portable device for very specific situation (which is why I bought my universal one) The low priced ones are really rubbish, so you will spend at least $150 on a universal stand. There is way more versatility, power & accuracy in a proper press. Hare & Forbes have some starting at low-ish prices (although I suggest you go & buy one off the floor so you can measure it for spindle runout etc - I had to return mine twice before I got one with acceptable tolerances, as I bought on-line.)

-

12th February 2016, 05:53 PM #8

I'd advise getting a tall drill press and then putting it on wheels - tuck it out of the way until needed

Why the tall one? I've the shorther and have found the I've needed to drill a straight hole (with a forstner) in the end of a piece of wood bigger than the gap. Not sure how I got around that now, hmmregards

Nick

veni, vidi, tornavi

Without wood it's just ...

-

12th February 2016, 07:39 PM #9

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,791

I agree the full height DP is the way to go but if a bench mounted drill press is mounted on the end of a bench the head can be swivelled so that the chuck is over the side of the bench. Of course this means the DP table cannot be used but some sort of workpiece support can still be wrangled to drill log pieces,

-

12th February 2016, 11:50 PM #10

Novice

Novice

- Join Date

- Feb 2016

- Location

- West of Sydney

- Age

- 47

- Posts

- 16

Wow thanks everyone for the great replies, its been really helpful. I *was* looking at el cheapo ebay stock, cast, etc, and it does look like a poorly timed blow from a feather would cause it considerable issues.

I will be looking into the drill press for certain, guess I'll join all the other hobbyists combing the classifieds.

Oh and thanks also for mentioning use of the drill press with long pieces of wood. Some of the dowel holes will need to be drilled into the ends of some fairly long beams (~1800), so I need to take this into consideration.

-

13th February 2016, 01:24 AM #11

For doweling operations, especially into the ends of long pieces, you will find that a horizontally mounted drill is much easier to use

Link https://woodgears.ca/horizontal_boring/jig.html

more sophisticated version

Link https://woodgears.ca/horizontal_boring/reuter.htmlregards from Alberta, Canada

ian

-

13th February 2016, 08:52 AM #12

Thanks Ian

pretty sensible ideas but I recall I didn't want to muck too much and probably did as Bob suggested - I usually do them on the lathe these days

(actually thinking about it I was more than likely drilling a blank for a longer chisel handle which didn't quite fit between centres)regards

Nick

veni, vidi, tornavi

Without wood it's just ...

-

13th February 2016, 11:43 AM #13

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- May 2004

- Location

- Sth. Island, Oz.

- Age

- 64

- Posts

- 754

In my opinion, there's 2 answers to your Q: both no & yes.

A drill stand can be an excellent quality, versatile & accurate boring aid. It can also be inaccurate, difficult & frustrating to use accurately. Exactly the same can be said for a drill press, but I venture to say that they are generally less versatile than a stand.

For precision, small scale work (jewellery, model making etc.) small scale (i.e. Proxxon et. al.) and medium scale (43mm collar) drill stands reign supreme. The medium ones are able to fit just about any quality drill on the market, from small precision high speed tools to low speed ultra high torque drills like Metabo's BE 75, to standard drills & hammer drills, and all models in between. There's even some German models with larger collar fittings for really big 1500w+ machines.

The "Metabo" drill stand illustrated above is an excellent example. Also marketed in Bosch livery, this is actually made in Germany as the smallest & lightest of Maxion's offerings. This company, specialising in precision boring instruments, manufactures a massive range of specialised drill presses and stands ranging from the simple stand illustrated to automated line boring machines costing hundreds of thousands of Euros. Having owned & used the Maxion stand I can confirm that it's an old design (dating back to the 70's) that was originally sold through Axminster's mail order business. The key to this particular model's success is not so much the stand itself, but the range of dedicated clamping aids that are available. In addition to the standard cast iron & alloy vices, there's angle-adjustable vices, milling tables with 2D dovetailed slides and worm drives and a particularly ingenious cam activated material clamp with integrated centering vees for cylinders on the forked clamp that sleeves over the stand's 40mm steel column. Having the column located at the stand's corner maximises the throat clearance. The headstock assembly may be securely clamped to the column, adjusted for auto return, or freely swivelled for outboard long boring duties.

With a drill stand you also get a versatile and useful electric drill as a "free" part of the package that can also be used for a huge range of tasks. In fact, one could say that the overall performance of a drill stand is a product not only of the stand's intrinsic merits, but also the virtues and vices of the donor drill too. Some drills (the interchangeable chuck SDS drills from Makita, Metabo or Bosch for example) make rather poor drill stand drives, as they tend to have chuck runout and concentricity issues.

Some manufacturers also offer accessory milling tables for wood & metal to fit their stands, or you could make your own. There's still some manufacturers (Metabo, AEG, B & D, Bosch, Kress) making extremely high speed 43mm collared, 1/4" and/or 8mm colletted routing/milling machines. In some instances, the variable speed and precision of these tools in an overhead, fixed spindle moulding mode is a near perfect solution for high precision small runs of mouldings. Dolls house & some musical instrument makers & architectural modellers love 'em!

Other stands offer adjustable drill mounting angle, with an angular scale, and even adjustable throat clearance (Wabeco et. al.) By their very nature, the addition of adjustability within a jig's headstock also introduces an element of unwanted flex in certain circumstances, limiting their usefulness to lighter workloads.

Record power still make one of the heaviest, most accurate and strongest drill stands available. In fact the stand is so strongly and accurately built that it has in the past been offered with well designed and precision manufactured hollow chisel morticer and miter guillotine attachments. It also forms the basis of the firm's dedicated RPMS75 hollow chisel morticer. I can't think of any other drill stand or even press that is realistically capable of the sort of morticing capacity of what some may sneeringly consider this "mere" drill stand!

Mounted horizontally, jigged and swivelled laterally, a precision drill stand is also eminently capable of accurate and repeatable center boring duties too.

Drill presses similarly are wildly varying in terms of overall quality. From a hundred or so to eye wateringly expensive engineering examples costing as much as you're willing to pay. When appropriately equipped with material clamping jigs, most are eminently capable of heavy duty drilling in a variety of materials. Angle & height adjustable work tables helps to increase versatility, whilst (in lower quality examples anyway) slightly compromising accuracy & repeatability.

A well made and accessorised drill stand will often be the equal in accuracy if not capacity of a dedicated bench drill, and will probably be more versatile (and a whole lot more portable) to boot. A well made (& expensive) floor standing press will normally be unequalled in terms of its capacity for heavy duty work especially.Sycophant to nobody!

-

13th February 2016, 11:45 AM #14

Hi Nick

those ideas are more for people, like Mr Sunny, who are looking to use the DP to drill dowel holes.

For dowels in the end of bed rails or table aprons, a drilling jig or horizontal borer is the way to goregards from Alberta, Canada

ian

-

13th February 2016, 04:33 PM #15

I have to agree with the general thrust of this conversation. A universal drill stand maybe ok in tight situations but lacks the intended purpose of a dedicated drill press. I have had two or three of these over the years. They don't hold the drill tightly enough and all of mine have cracked.

I wouldn't waste my money again,thats my two cents worth.

Sent from my SM-G900I using Tapatalk

Similar Threads

-

Drill Press vs Normal Drill on stand

By johno_84 in forum HAND TOOLS - POWEREDReplies: 7Last Post: 1st October 2021, 01:55 PM -

Shop Made Drill Press Stand

By andrewr79 in forum THE SHEDReplies: 3Last Post: 26th January 2013, 11:19 AM -

Drill Press stand....

By brucen in forum WOODWORK - GENERALReplies: 2Last Post: 3rd September 2005, 02:52 AM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote