Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 14 of 14

Thread: African Blackwood wanted

-

10th February 2016, 06:30 PM #1

African Blackwood wanted

African Blackwood wanted

Where can I purchase, or does someone here sell, African Blackwood? .... the blacker the better.

Please contact me or put me in touch here with a supplier in Oz.

I just need enough to make a dozen (12) drawer handles: each will be about 150mm long x 30mm high x 20mm wide.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

10th February 2016 06:30 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

10th February 2016, 06:47 PM #2

Taking a break

Taking a break

- Join Date

- Aug 2008

- Location

- Melbourne

- Age

- 34

- Posts

- 6,127

-

11th February 2016, 02:34 PM #3

Hi Derek

You specify "the blacker the better" would Austalian Ebony be an alternative?regards from Alberta, Canada

ian

-

11th February 2016, 03:33 PM #4

Hi Ian

I've never seen any, never mind used it. Is it uniformly black or near black?

I am not quite at the stage for the handles, but it should not be too far off, and I must plan this now. The drawer making takes up all my free time in the workshop. I must find time to make a couple of handles: one in Jarrah, and one in ebonised Jarrah, and then compare them.

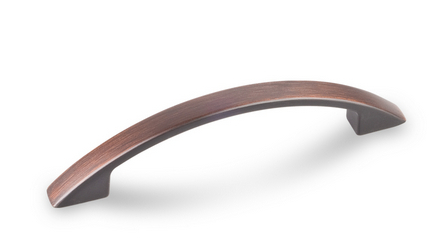

This is quite close to what I have in mind ...

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

11th February 2016, 04:02 PM #5

I believe the tools in Collaboration No.1 are Aust Ebony

regards from Alberta, Canada

regards from Alberta, Canada

ian

-

12th February 2016, 01:20 AM #6

-

12th February 2016, 01:35 AM #7

Hi Ian

I have thought long and hard about construction here. My first plan was to laminate the curves, as you suggest. It seemed the best way for strength. The problem with this method is that the base sections (for the screws) will need to be glued on, and the join will be a weak area.

Consequently, I have decided to saw it out of a single piece of wood. Grain direction is important to maximise strength. The long section will not be flat on the underside, but half-round. That will add to the strength of the handle, as well as create a comfortable hold. I have M4 steel bushings for the bases. This will reduce the stresses there.

I have planned to rough out a wide version, enough for 4 handles, then slice them up, and them finish each individually. That should make it easier to ensure uniformity.

Thoughts?

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

12th February 2016, 02:20 AM #8

I'd still go with a bent lamination and incorporate the screw points in the first strip.

hopefully the attached diagram makes that clearerregards from Alberta, Canada

ian

-

12th February 2016, 02:57 AM #9

Hi Ian

That does make sense. I will try building one with and one without - see if there is any advantage in strength.

Must get the drawers done first. I am not getting enough time in the workshop!

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

9th June 2016, 07:19 PM #10

New Member

New Member

- Join Date

- Apr 2010

- Location

- Victoria

- Posts

- 7

what is the minimum dimension you need?

-

9th June 2016, 08:22 PM #11

If it just needs to be hard and black you could always ebonise any of your WA species, like an acacia or even Jarrah, with the old vinegar/steelwood/tea bag. Paint on and let dry in the sun, if not black enough repeat application etc.

Neil____________________________________________Every day presents an opportunity to learn something new

-

9th June 2016, 08:50 PM #12

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Aug 2013

- Location

- Montmorency Victoria

- Posts

- 554

-

9th June 2016, 09:08 PM #13

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

Derek,

Call Carbatec Brisbane. They had a bunch of it.

I priced it at around 75k per cube, from memory.

Hope that helps.

Cheers,

Luke

-

9th June 2016, 09:09 PM #14

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

Similar Threads

-

African Blackwood

By DaleBagpipes in forum TIMBERReplies: 0Last Post: 23rd September 2011, 10:41 AM -

African Blackwood

By bdar in forum WOODTURNING - PEN TURNINGReplies: 8Last Post: 14th August 2007, 08:20 PM -

African blackwood and african olive wood

By Solaris in forum TIMBERReplies: 21Last Post: 11th May 2006, 07:33 PM

Thanks:

Thanks:

Reply With Quote

Reply With Quote