Needs Pictures: 0

Needs Pictures: 0

Results 1 to 15 of 41

Thread: Chisel - Sharpness

-

26th July 2023, 01:28 PM #1

Chisel - Sharpness

Chisel - Sharpness

How sharp are your chisels?

Just received some promotional material from Australian Wood Review Magazine which includes a repeat of an article by Iain Green several years ago on Japanese Sashimono joinery. One photo really caught my attention:

Chisel End Grain.jpg AWR #59

Notice how effortlessly Green is shaving that end grain and how uniform the shaving is. And reflect on the skill and effort embedded in sharpening that chisel.

-

26th July 2023 01:28 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

26th July 2023, 11:50 PM #2

Senior Member

Senior Member

- Join Date

- Apr 2020

- Location

- USA

- Posts

- 122

These types of demonstrations depend also on the type of wood used. It looks like mahogany (or something similar) in the picture. Given enough time spent on it, you can sharpen any chisel, made with the right kind of steel, to a very sharp level.

I'd say that on a typical day at the workshop my chisels are sharp, but I don't spend more than a one or two minutes sharpening any one of them.

-

27th July 2023, 12:33 AM #3

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2010

- Location

- US

- Posts

- 3,132

I would expect all of my bench and paring chisels to do that without issue. the only catch is whether or not something gets nicked and you have to go back to the stones if the appearance is important, but the time at the stones is a minute or two.

I remember eons ago reading Warren Mickley talk about how he never really deals with edge damage and doesn't feel like it should be tolerated once one has experience. I agree with what he's saying - and I get it from his context. He works by hand and does a fair amount of carving or chisel work that shows on forms or fixtures that he's hired to make or finish and:

1) if edges are not at the level of sharpness of this picture, you will literally get less done even with sharpening time considered, and it's far more effort to work

2) when you find a point that edges don't really fail and are still sharp, the time may be in initial setup, but it's not very much in terms of sharpening time.

I would guess five minutes of total time for a case full of dovetails all the way around (including removal of all wood from half blinds - I've never used a router for that - too risky for me with my level of power tool use).

Raffo is right about the wood. if you tried to cut oak back against the grain like that, or older douglas fir or spruce, it would break out across the top no matter how sharp your chisel. cuban and honduran mahogany instantly convey to you why they were so well liked. They even *sand* better than other woods.

-

27th July 2023, 01:36 AM #4

Senior Member

Senior Member

- Join Date

- Feb 2023

- Location

- Perth

- Posts

- 385

Hi Graeme

One can make a chisel sharp quickly. Some quick method have developed. - see this youtube Sharpen the worst rusty vintage bench chisel imaginable in 4 minutes (FOR CHEAP!)!!! - YouTube

The inverted method of using a sharpening disk seems to work well even freehand. You cannot see what happening but easier to hold to chisel still this way with the bevel facing back towards you.

For info I use a 10 dollar diamond lapidary disk, pretty high grit and a honing leather on top of the disk. Occasionally I might refine a bit on a stone by hand particularly the backside the first time around. But mostly use 2 step process- grind then hone. Very quick. The chisels edges can slice quite a few wood endgrains, but not all.

A bit influenced by David in moving to an abbreviated process.

-

27th July 2023, 03:01 AM #5

Senior Member

Senior Member

- Join Date

- Apr 2020

- Location

- USA

- Posts

- 122

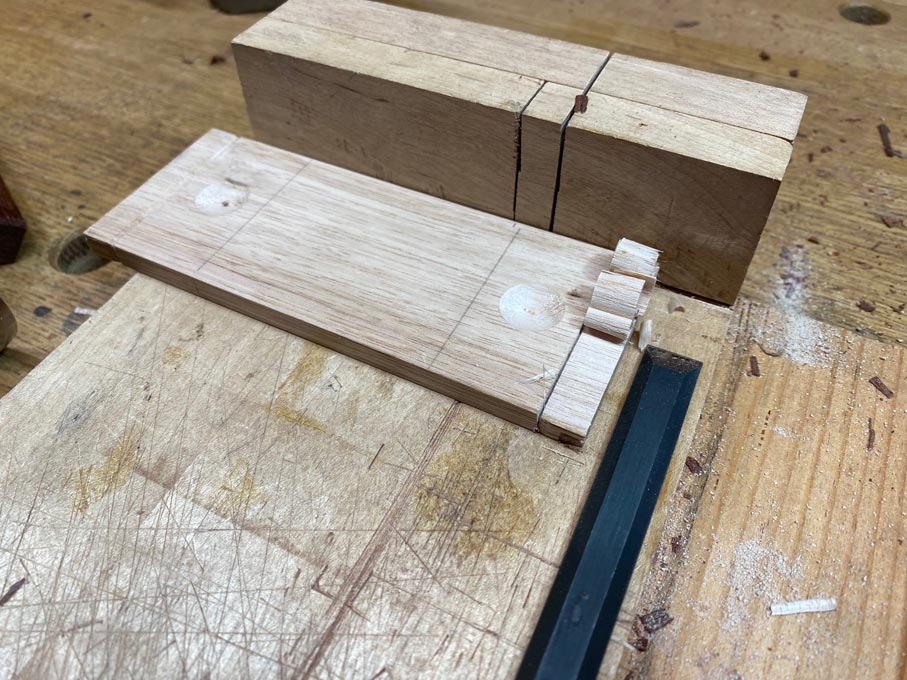

Tried a quick test using a piece of white pine. The wedge I already had, it's a piece of oak. The picture is a bit blurry and the test was hurried, but it wasn't that difficult to get some smooth shavings. There are other details about doing something like this that are not obvious until you actually do it: holding the piece will need something more than your fingers to keep it in place, the piece being cut needs to be soft and/or thin to be able to slice it as shown in OP picture, the chisel will dig into the reference wedge if used like in the OP picture (I gouged my wedge), holding the piece as shown in both pictures risks cutting yourself, etc.

Aren't Paulownia and other relatively soft woods used in Japanese furniture? These precise slicing cuts are not difficult to achieve with these type of woods. Reproducing these tricks on harder woods like hard maple, white oak, etc. is not so easy.

I don't see what is remarkable about what the individual in the OP picture is doing. A sharp enough chisel can make very nice thin slicing cuts.

20230726_090911.jpg

-

27th July 2023, 03:12 AM #6

Tassie Oak. Paring tenons. Dating from 2 days ago (Nightstand Build) . The wood is responsible for the grainy surface ...

Basic stuff.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

27th July 2023, 04:42 AM #7

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2010

- Location

- US

- Posts

- 3,132

well, it's back against the grain, but mahogany will allow that. Beech will tolerate it a little and apple is very forgiving (though far harder to push a chisel through than mahogany). you have to take lighter cuts but there is a point where it's easier to plane something (ebonies, etc) for sure.

-

27th July 2023, 04:43 AM #8

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2010

- Location

- US

- Posts

- 3,132

-

27th July 2023, 07:23 AM #9

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2010

- Location

- US

- Posts

- 3,132

(not saying the chisel isn't sharp or that some of the fibers aren't severed with those that are rolled off. I see the type of tasmanian oak is about as hard as our oak, which isn't a great predictor of how chiseling and malleting go, but certainly I'm sure your chisel would take a pared bevel off.

In the states, heart beech and apple are both harder than red oak, but both also pare much more nicely and smoothly.

-

27th July 2023, 07:49 AM #10

GOLD MEMBER

GOLD MEMBER

- Join Date

- Oct 2018

- Location

- Dandenong Ranges

- Posts

- 1,893

From my limited experience, all the fruit tree timbers are lovely to work.

-

27th July 2023, 04:12 PM #11

Now try paring the endgrain of that mountain ash, Derek. My guess is that your chisels will be up to the job.

Paring End Grain.jpg Photo: Derek

-

27th July 2023, 04:19 PM #12

-

27th July 2023, 06:33 PM #13

Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

28th July 2023, 01:51 AM #14

Senior Member

Senior Member

- Join Date

- Apr 2020

- Location

- USA

- Posts

- 122

Derek, in your example you're paring down with the back of the chisel riding the guide. It's not the same as what the OP picture is showing, where the edge of the chisel is riding the guide.

Seems like you think I'm saying you can't pare hard woods. You misunderstand, I was just pointing out that how it was shown in the OP picture, it was a precarious operation and probably easy with thin and soft wood.

Maybe you can refute my opinion if you actually reproduced what the picture shows.

-

28th July 2023, 03:31 AM #15

Hi Raffo

To be honest, I was not posting for any message or effect. Just something that was a shaving in end grain (from file photos). Controlling a shaving is not a big deal, hence the cross-grain tenon example. Below is soft Jacaranda without any support.

I will add that paring Jarrah, as in the earlier post, was a big deal. The wood is very hard and going in square-on is likely to cause the chisel to skip over the wood. Skewing the blade enables the corner to catch and start the cut. Planing without the guide is sometimes a lot easier and you can start thicker and then thin down the shaving. Starting with a thin shaving is tough with hard woods.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

Chisel sharpness testing

By qwertyu in forum HAND TOOLS - UNPOWEREDReplies: 24Last Post: 8th January 2021, 07:22 AM -

Testing for sharpness

By Luke Maddux in forum HAND TOOLS - UNPOWEREDReplies: 14Last Post: 11th October 2015, 09:01 PM -

Ponderings - Determining sharpness

By Toolin Around in forum SHARPENINGReplies: 10Last Post: 3rd January 2008, 08:15 PM -

How do you test sharpness?

By Tiger in forum HAND TOOLS - UNPOWEREDReplies: 39Last Post: 18th May 2007, 07:12 PM -

Test of sharpness

By Tiger in forum WOODTURNING - GENERALReplies: 31Last Post: 10th April 2006, 02:22 PM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote