Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 12 of 12

Thread: Comparing chisel steels

-

5th June 2013, 03:50 AM #1

Comparing chisel steels

Comparing chisel steels

Call it multitasking

While building the current project, a blanket chest, I took the time to do a few reviews, one of which was to compare 4 different chisels .. 5 if you add in the chisel that tidied up after some of the others.

While building the current project, a blanket chest, I took the time to do a few reviews, one of which was to compare 4 different chisels .. 5 if you add in the chisel that tidied up after some of the others.

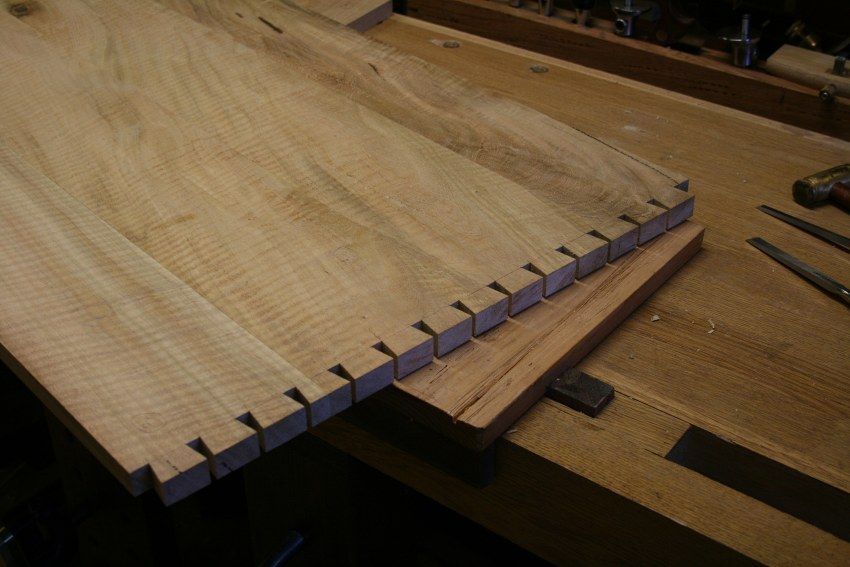

The wood used is 3/4" thick Curly Marri. This is hard - not quite as hard as Jarrah overall (although sections were very hard indeed), but i can only describe it as "chewy". That is, it is extremely interlocked and it resisted attempts to drive a chisel through it. Where Jarrah is very hard, it is also brittle and breaks away. This Curly Marri just did not let go. Firewood. Beautiful firewood.

I did not set out to compare chisels when I began dovetailing the sides. This thought occurred to me when I was into the first side. I decided to continue as I had begun: using two chisels, one for the tails, and one for the pins. The tails would be comfortably cut only by pushing the 1/4" chisel (frankly, anything wider would not penetrate the wood). The 3/4" chisel would be used with a mallet (I did persevere with pushing where possible, and now have a painful rotator cuff for my pains).

The boards are 20" across. There are 13 tails 3/4" at the baseline (the ratio is 1:6 for those curious), and 14 pins with 1" at the back and 1 1/4" at the front.

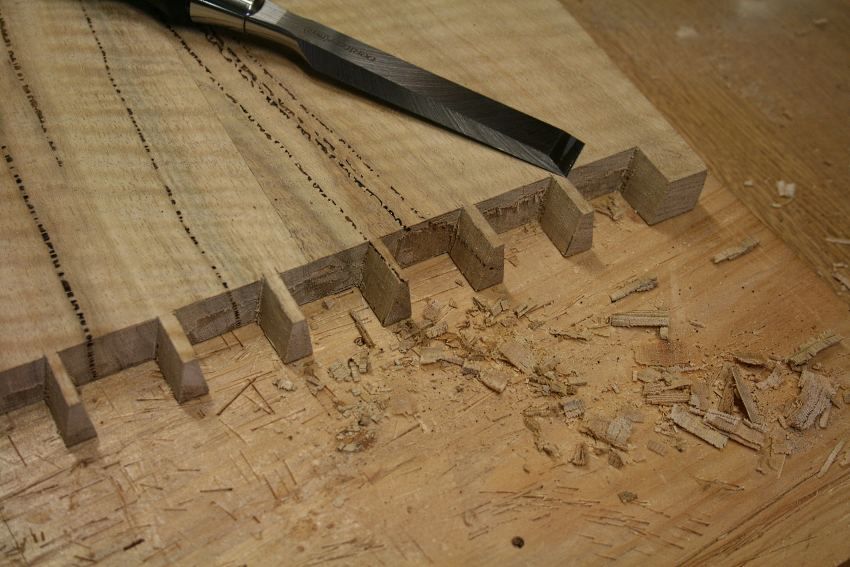

Most of the dovetail waste was removed with a fretsaw, and it was the remainder that constituted the test material ...

The chisels used (in order) were the Veritas PM-V11, Stanley #750 (which is a HCS similar to O1, but I am unsure of the specific type), Koyamaichi white steel, and Blue Spruce A2. All the bevels of the 1/4" chisels were ground and honed at 30 degrees, while all the 3/4" chisels bar the Veritas were also at 30 degrees. The Veritas was at 25 degrees (why? Because I use it that way and did not think to change the bevel angle).

Paring ended when the chisel could not easily cut and then failed a pine end grain attempt ...

All dovetails were pared half-way through one side, then the board was flipped over and the other side done. In this way a board may be said to have 26 tail and 28 pin cuts.

The tails were cut first.

Both the PM-V11 and the White Steel had no difficulty paring 26 cuts (both sides of the tails, an example is above).

The Stanley could only manage 3 cuts ...

The A2 did a little better with 7 cuts ..

With the 3/4" chisel on the pin board, both the PM-V11 and the White Steel were able to do most of both sides. 22 1/2" (out of 31 1/2") of pin length for the PM-V11 and 27 1/2" of pin length for the White Steel.

PM-V11 cleaning up ...

White Steel at work (I managed to push these, then required a hammer to continue) ...

The Stanley managed 4" in all, failing on the 5th ..

The A2 completed 7" ..

What of the fifth chisel I mentioned early on? To clean up when a chisel stopped working, I used a Funmatsu-Nezumi-Haisu (from Tools from Japan). This is a PM-HSS chisel. A right royal pain in the bottom to sharpen, but it holds an edge like nothing else ...

Summing up: The PM-V11 and the White Steel really do deliver. The gap between them and the A2 and O1/HCS is very large. There is no appreciable extra effort to hone the steels when used with modern waterstones, such as Shaptons (used here) or Sigmas.

It must be emphasised that this was about the steel, not the chisels. What do I mean by that? A chisel is not simply a lump of steel with a handle. Edge-holding is sometimes less important than balance and control and comfort when in use. The Stanley here is one of my favourite users as I customed the handles for myself. The Blue Spruce are one of the nicest chisels around, which arguably the best handles made on this planet. The Veritas handles are really excellent as well, and the balance in use is surprisingly good, and they are lighter than they look, but not as light as the BS. All good chisels. It is only when one works mongrel wood that good steel becomes a dominating factor.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

5th June 2013 03:50 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

5th June 2013, 06:20 AM #2

well aged but not old

well aged but not old

- Join Date

- Sep 2004

- Location

- Brisbane

- Posts

- 925

My daughter lives within a stones throw of the Veritas shop in Vancouver. When she comes home to visit shortly she will be bringing with her a set of pm v 11 chisels and a large router plane + blades + inlay cutters. The cost of the 5 pmv 11 chisels bought and delivered this way is about $330 compared to over $600 bought locally. I cannot understand why there is such a vast difference.

I have been using a set of old Stanley chisels for many years and while they are okay in softer woods as soon as the timber gets hard they lose their edge very quickly. Your little review backs up all I have read about The pmv 11 chisels. I have heard that for all the strength of their edge holding ability that they can be sharpened with waterstones and will take low angles eg 25 degrees. True or not?

I cannot wait to get my hands on them and the sight of my beautiful daughter enhanced with beautiful chisels will be wonderful.

By the way I once made a Shaker style step stool in Mango.It had vast numbers of dovetails and I finished up with very sore elbows from it.My age is still less than my number of posts

-

5th June 2013, 03:12 PM #3

Hi ChookI have heard that for all the strength of their edge holding ability that they can be sharpened with waterstones and will take low angles eg 25 degrees. True or not?

Hi ChookI have heard that for all the strength of their edge holding ability that they can be sharpened with waterstones and will take low angles eg 25 degrees. True or not?

All true. The PM-V11 hone about the same as A2. However, where A2 is reputed to chip under 30 degrees, PM-V11 may be ground at 20 degrees.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

6th June 2013, 02:48 PM #4

Derek, just as a matter of interest - what is the way to read the name of this new wonder steel?

Is it PM-V-eleven?

or

PM-seven (i.e. reading the last bit as Roman numeral VII)?

or

PM-vee-2 (just reading the last II as Roman numerals)?

My confusion stems from the different ways people choose to type it.....

Cheers,IW

-

6th June 2013, 03:22 PM #5

Hi Derek,

Excellent review as always, Nice clean dovetails as well.

Do you have any thoughts on how M2 compares? Obviously I'm thinking of the forum chisels as I ask this.

The only maker using M2** that I'm aware of is Harold and Saxon, and their web site mentions D2, but all the products use M2?

Regards

Ray

** Apart from the turning chisel makers, that seem to favour the HSS M2

PS.. Ian I thought it was pee-emm-vee-too, as in Powdered Metallurgy Version Two... but I'm most likely wrong

-

6th June 2013, 06:27 PM #6

Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

6th June 2013, 08:47 PM #7

Hi Ray

The reason why many favour HCS in plane and chisel blades is that the grain is small and tightly packed, and this creates a sharper edge. By comparison, M2 and D2 are coarser grained (largely due to the inclusion of additives such as chromium), and they do not get as sharp as easily as the finer grained steels. This is the official explanation.

I am not so sure about all that. I understand the theory, but my practice is that M2 and D2 can get very sharp indeed - however they do require a lot more work to do so. That is their main drawback, and possibly the reason why many find that they do not get as sharp - simply, that they do not complete the sharpening process, as it is an extended one. I've not used the H&S or the HNT Gordon M2 blades. I do have a few by Mujingfang, and they get sharp as anything else.

Given a choice of M2 and PM-V11, I'd go for the latter. But only because the powdered metal steels allow one to dial in the properties with some predictability. This is like mixing up a recipe, and the result is a fine grained steel, which will get very sharp according to the theory (and in practice).

On the other hand, one cannot ignore the heat treating ...... blade ease of use and durability is more a sum of the parts. Philip Marcou explained to me how he likes D2 steel. The D2 I have used is a bear to sharpen. In his eyes this is because it is too hard, and he would make his blades softer, which would enable it to be sharpened more easily.

As you know, steel will fail in one of two, perhaps three ways.

If an edge is too brittle, it will chip.

If an edge is too soft, it will fold over.

If an edge is just right, it will wear to a round.

Just because an edge chips does not mean that the steel is too brittle/hard. It does depend on the nature of the stress the steel has been put under. Hammering a chisel through thick sections asks a lot of edges. Mortice chisels have thick blades for that reason. Note that there was a big difference in the amount of work done by the A2 and the PM-V11, yet both showed micro chipping. This suggests different factors for each - The A2 did not handle the hard wood as well as the PM-V11, which eventually chipped, suggesting it was made as hard as possible to last long, and could handle this.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

6th June 2013, 10:40 PM #8

Thanks Derek,

Interesting technology, I have been reading up on PMV-11 on here PM-V11 - Home

This diagram ( from that link above ) I found very useful,

They mention M2 in the text but don't show any of the M2 data, so I'd have to assume it's characteristics are somewhat similar to M4.

It would be interesting to see White Steel on the same diagram.

Regards

Ray

-

6th June 2013, 11:18 PM #9

Hi Ray

You cannot equate M2 with M4. M4 is a PM with fine grain, and has much greater abrasion resistance than M2.

Here is a comparison ..

Regards fro Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

7th June 2013, 12:29 AM #10

Some time back (6 months?) when pm-v11 was first mentioned here, someone posted up a link to a very thorough discussion on types of metals.

I had taken away from that that the "v11" part meant 11% Vanadium ... although writing it now that seems like a lot.

I see Derek's chart mentions 10V, 9V and 3V. Cannot explain "440 V" 'though.

Paul

I'm pretty sure this was it, from rsser ... https://www.woodworkforums.com/f127/s...4/#post1482344

Crucible Tool Steel and Specialty Alloy General Information

-

7th June 2013, 12:37 AM #11

Hi Derek,

The M4 I'm aware of is almost a dead ringer for M2,

The chart refers to CPM M4, which is obviously Powdered Metallurgy, the M4 I'm thinking of is not.

At some point in this discussion, we will need a metallurgist to come to the party and clarify the confusion.

All the same, those PM-V11 results look very impressive.

Regards

Ray

-

16th June 2013, 08:12 AM #12

well aged but not old

well aged but not old

- Join Date

- Sep 2004

- Location

- Brisbane

- Posts

- 925

Dear Derek

This is a very interesting thread. Another thing I noticed in the pictures was the clean cuts on the sides of the dovetails. What dovetail saw did you use to cut these?

Thank youMy age is still less than my number of posts

Similar Threads

-

Comparing high and low frequency decibel readings

By Fuzzie in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 3Last Post: 24th March 2013, 10:29 PM -

Chisel Paring - 6 steels

By derekcohen in forum HAND TOOLS - UNPOWEREDReplies: 4Last Post: 30th May 2011, 08:38 PM -

Chisel Blade Testing - 5 Steels

By derekcohen in forum HAND TOOLS - UNPOWEREDReplies: 9Last Post: 17th May 2011, 06:32 PM -

Source for Comparing Tablesaws

By Steverino in forum HAND TOOLS - POWEREDReplies: 8Last Post: 15th September 2005, 01:16 PM -

Comparing 16/18" Bandsaws

By HappyHammer in forum HAND TOOLS - POWEREDReplies: 13Last Post: 28th February 2005, 01:25 PM

Likes:

Likes:

Reply With Quote

Reply With Quote