Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 30 of 72

Thread: Diamond Lapping Film

-

6th January 2012, 01:38 PM #16

Hi Eddie

Your Sigma is 120 grit. The DMT is 375 grit. I would expect the Sigma to cut faster. In fact I would never lap with 375 grit -it is always going to be slow, regardless of the medium. I would only recommend starting with 120 grit. I use 40 micron diamond paste on cast iron, which is about the same as a coarse DMT, however I only lap immediately behind the edge.

And, yes, the films are for sharpening, not flattening the backs of blades.

I completed quite assessment of quite an extensive array of grits. At the start of the evaluation I used water to lubricate and carry away the swarf. This was recommended by LV. I quickly changed this to water-plus-detergent, which was a big improvement. Later I suggested Camilia oil, which was an even bigger improvement.

Testing the films on softer steels is a lot like testing plane blades on straight-grained woods - it is less likely that you will find important differences when the conditions are easy. Using harder/abrasion-resistant steels, such as 3V, M2 and M4, and D2, really shows up the potential of these films. They work just as well on the O1 and A2 steels, but then the differences with a Shapton or even an oilstone will be reduced significantly.

In the end I can say that the films are amazing for what they can do, especially with PM steels. I like the fact that they remain flat without any work. I have zero problems with swarf using Camilia oil.

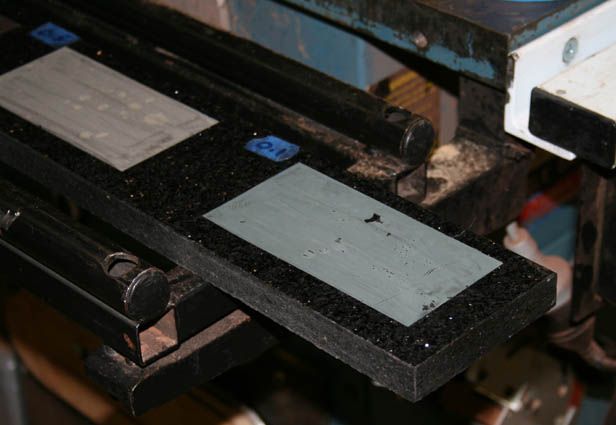

Here is my "sharpening centre" (Thanks Pops) - a 1" thick length of flat granite ...

Note: my film is not the standard 6x3". I was using large sheets and cut them down to get maximum wear. I did suggest that the the 6x3" be used as I believe that this is all one needs ... and the price is lower. We are used to 8" long waterstones because that is how they have always been sold. But a 6" medium is absolutely fine with me, whether freehanding (especially freehanding!) or using a guide (one doe not need much work on a edge using these films).

One last point - it is apparent that there are air bubbles under my film. It wasn't an issue. These films have done about 100 cycles.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

6th January 2012 01:38 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

6th January 2012, 02:19 PM #17

Interesting point raised there Derek. I have to wonder about the difference in flatness of a polished piece of "kitchen granite" as opposed to a "reference" piece. With so many people using float glass as well, I ask the question: Is the biggest difference the sheet of specifications paper that comes with it?

I have a sheet of granite 750x500mm onto which I have strapped four strips of Colour Coded Grit (timber frame with embedded nuts and screw in clamps). It's absolutely excellent for flat sanding lengths of timber <600mm. I can also clamp my Woodpeckers DP3 Drill Press Fence onto it if I want get a 90 degree reference corner (i.e. miniature Jointer). I have used it for scary sharpening on WD as well, and the resultant shavings were very fine.

Cheers, FF

-

6th January 2012, 04:16 PM #18

Hi Brett

While the total length of the granite may show some deviation (although in reality none as measured by a straight edge), my honing takes place over a length of 6". Indeed, if I am freehanding a blade, the effective length is of little importance.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

6th January 2012, 04:45 PM #19

Hewer of wood

Hewer of wood

- Join Date

- Jan 2002

- Location

- Melbourne, Aus.

- Age

- 71

- Posts

- 12,746

Cheers, Ern

Cheers, Ern

-

21st January 2012, 02:38 PM #20

Novice

Novice

- Join Date

- Jan 2012

- Location

- USA

- Posts

- 24

Recently Revisited the Diamond Films

Recently Revisited the Diamond Films

I purchased diamond film a while back while trying a CPM 3V plane iron. After reading the recently posted comments I decided to try it again.

I had just finished surface grinding an 0-1 iron that was going into a plane that I had just completed. Granted I was particular with the last passes on the surface grinder, tight overlaps and 3/10ths depth of cut, which typically makes polishing the backs of these irons easier and much less time consuming.

I started as usual by adhering a pieces of 320 psa backed abrasive to a surface to plate to create the initial scratch pattern. I then switched to a piece of diamond lapping film 15 micron. I was amazed at how quickly I refined the back of the iron to the 15 micron level of polish. I then progressed to a piece of 9 micron, and then on to a piece of 1 micron film. I literally had the back of that iron to a working polish in 5 minutes tops.

Using the standard 3m films this process would have taken me anywhere from 15 to 25 minutes and I would have used more abrasive media in the process. Given the time savings and the use of less material these films may not really cost that much more to use.

As an aside I always use abrasive film on a piece of granite to work the backs of my irons, even when I use water stones on the bevels. That granite plate is going to be the same every time which is more than you can say for any type water stone. Consistency is the key here.

Ron Brese

Brese Plane, Hand Planes for Woodworking

-

21st January 2012, 02:58 PM #21

Hewer of wood

Hewer of wood

- Join Date

- Jan 2002

- Location

- Melbourne, Aus.

- Age

- 71

- Posts

- 12,746

Good info Ron. Thanks for the post.

Sounds time-effective.

Cost-effective may need some more looking into ... referring to how long the V. diamond film lasts (at 3"x6") cp. 3M (at c. 8.5"x11"). V SiC grains etc etc.Cheers, Ern

-

21st January 2012, 04:44 PM #22

Welcome Ron! I had not noticed a post from you here before now.

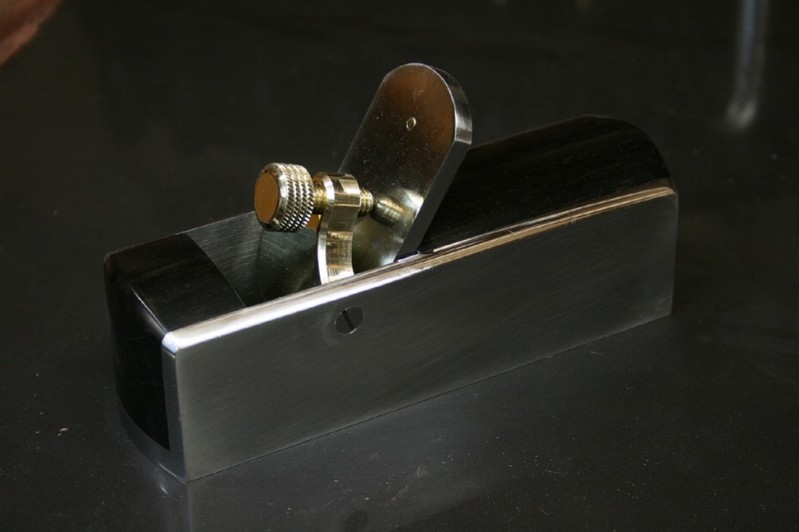

For those unfamiliar with Ron Brese, he makes extraordinarily good handplanes. He was responsible for the kit that built this ...

There are considerably better planes on his website: Brese Plane, Hand Planes for Woodworking

Another example ...

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

22nd January 2012, 02:02 PM #23

Novice

Novice

- Join Date

- Jan 2012

- Location

- USA

- Posts

- 24

Efficient use of honing film

Efficient use of honing film

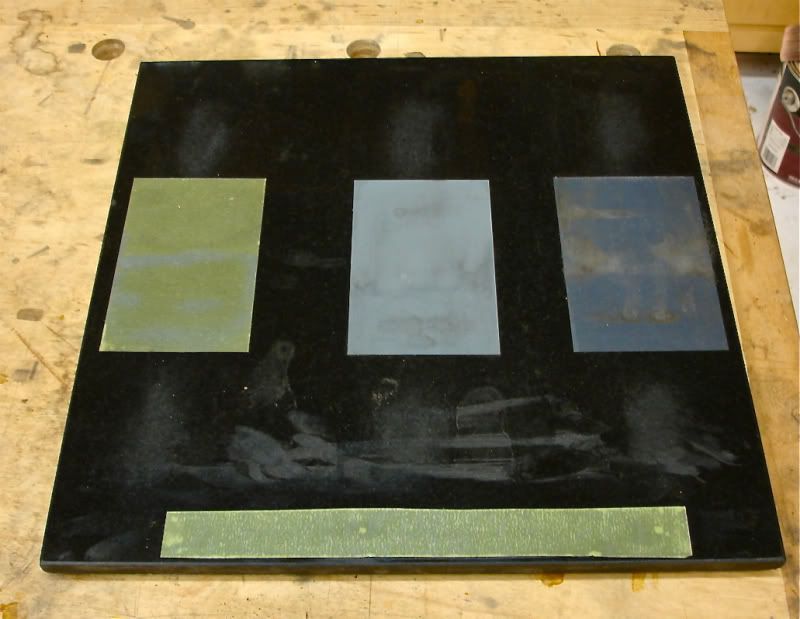

This film as well as the 3m micro abrasive is quite conducive to honing with micro bevels. Removing material from broad surfaces is not what it does well. The media also needs to be set up for use in a way that allows one to use the entire surface of the film.

Consider also the presence of psa adhesive between the film and the substrate so it will never be as firm as a stone. However with proper technique you can achieve a very refined edge.

The plate in the picture is set up so that the film can be approached from either side which means there's no need to have the wheel of the honing guide on the film. Given the layer of adhesive the wheel could very well track the film, but the key idea is to get the most sharpening done with the smallest piece of abrasive. As you get to the finer abrasive it's advisable to lighten up the pressure when working the bevel.

If you've used lapping film as well as stones you may have notice when you work the bevel on the stones there is still a burr that needs to be removed after your 8000 grit stone, whereas when you completed working the bevel on 1 micron or finer film the burr may have been almost impossible to detect. I suspect that this could be due to too much pressure on the edge of the iron causing it to impress into the film somewhat therefore removing the burr from a slight rolling of the surface.

This diamond material as well as the 3m film will give you a very polished micro bevel, and may look more polished than the micro bevel that comes off an 8000 grit water stone, however the surface left on the wood may be just as polished with either honing media. I sometimes feel it might be possible that the edge off the stone is just a bit crisper.

This is what I've found with extensive use of all three materials, your mileage may vary.

Ron

-

22nd January 2012, 02:14 PM #24

Thanks Ron,

Fantastic to have someone such as yourself adding to these forums.

Regards,

Frank

In trying to learn a little about everything,

you become masters of nothing.

-

22nd January 2012, 03:48 PM #25

Hewer of wood

Hewer of wood

- Join Date

- Jan 2002

- Location

- Melbourne, Aus.

- Age

- 71

- Posts

- 12,746

Thanks Ron.

I'm an old tool rehabber. Lapping is most of the work. Your point noted. Will have a play anyway.

Gorgeous planes you make. (Tongue hanging out).

Another option for rehab tragics is this. Not tried it.

Declaration: no connection with either supplier.

Post edited at Frank's request to remove the comment about his sig line.Cheers, Ern

-

23rd January 2012, 03:34 PM #26

Hewer of wood

Hewer of wood

- Join Date

- Jan 2002

- Location

- Melbourne, Aus.

- Age

- 71

- Posts

- 12,746

To add: LV describe this kit as lapping film. I think it better described as honing film.

Lapping in my book means flattening. 15 mu in anything can flatten a back with effort but there are far more effective means.Cheers, Ern

-

23rd January 2012, 03:55 PM #27

Hi Ern

I agree with your definition. Lapping is the term I use when flattening something (back of a blade, sole of a plane). Honing is synonymous with sharpening. While the details in the LV brochure are unlikely to confuse anyone about the intent of the film, they may move past it in an index.

I imagine that the name comes from the manufacturer and for original audience for which it was targeted, electronics, engineering, etc. It was not originally conceived as an aid for sharpening blades.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

23rd January 2012, 04:35 PM #28

In Engineering parlance we always referred to lapping when getting two surfaces to mate precisely with each other, by using a fine abrasive between them, one example could be the slide valves in a steam engine. This would be done after Flattening each of the two surfaces, separately. Other examples would include curved surfaces, such as lapping in the needle valves of injectors on diesel engines.

Honing was used used to refer to the final process of sharpening, using the finest of abrasives or just an untreated leather strop.

For woodworking tools I think the correct terminology would be flattening the backs of blades, then honing of the cutting edge.

However, ingrish is not spoke like what it were, so there are probably many versions

Regards

-

24th January 2012, 06:06 PM #29

Hewer of wood

Hewer of wood

- Join Date

- Jan 2002

- Location

- Melbourne, Aus.

- Age

- 71

- Posts

- 12,746

Yeah, Alice in Wonderland: a word means what I say it means ;-)

A forum member who was in the biz said that the 3M micro-finishing abrasives were originally developed for optic fibre production.

Whatever, as my kids used to say.Cheers, Ern

-

31st January 2012, 12:59 PM #30

Novice

Novice

- Join Date

- Oct 2008

- Location

- Ottawa, Ontario, Canada

- Posts

- 16

Diamond film

Diamond film

So, after reading Derek's post on the subject, I went down to Lee Valley for my weekly fix and bought the set of 4 films. I should have saved my money and just bought the two finest ones. I normally sharpen/hone with a 700 gr Bester, 4000/8000 Norton and a rub on the green honing compound on hard maple. The green film seems to be about the same grit as the green honing compound, but cuts more quickly. The 0.1 micron stuff is amazing - a couple or three strokes on the bevel, a couple on the back and wow - super sharp on O1, A2 and the Mn stuff in the Narex chisels (super bargain in my opinion). Thanks Derek.

Cheers

Jack

Similar Threads

-

3M Microfinishing lapping film

By groeneaj in forum SHARPENINGReplies: 7Last Post: 18th December 2011, 08:24 AM -

3M Imperial lapping film: first impressions

By rsser in forum SHARPENINGReplies: 9Last Post: 23rd June 2011, 02:04 PM -

Lapping a dog

By rsser in forum SHARPENINGReplies: 0Last Post: 22nd June 2011, 05:43 PM -

What oil to use in lapping a plane.

By Christos in forum HAND TOOLS - UNPOWEREDReplies: 2Last Post: 10th April 2011, 11:29 PM -

Gloat, and lapping #4-1/2

By LineLefty in forum HAND TOOLS - UNPOWEREDReplies: 12Last Post: 8th June 2005, 09:10 PM

Reply With Quote

Reply With Quote