Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 10 of 10

-

3rd October 2008, 11:45 PM #1

Difficult grain and tearout. Scraper or plane?

Difficult grain and tearout. Scraper or plane?

Hi guys,

I have started on a small project using some of the hardwood I got from the September Hardwood sale. The project involves a glued up panel. The pieces were joined and thicknessed and glued. The problem is one of the pieces has a lot of tearout, very intersting challenging grain, but hard to sort out.

I have tried with a handplane and got some of the gouges from the thickneser out and then used a cabinet scraper which has also helped. The problem is there is still a great deal of work to do and I dont like the idea of burning my finger tips working the scraper for hours. Also the calluses are not a good look when I get to examine my patients during the weekdays .

.

I thought of getting one of those scraping planes. Specifically the veritas one. Are they any good? Am I better off grinding a plane blade at a very high angle or getting one of those LV planes with a toothed angle, or something fancy like that?

Any help will be appreciated. I should also say that I am not tat keen attacking the panel with a belt sander!

regards

MariosYou can never have enough planes, that is why Mr Stanley invented the 1/2s

-

3rd October 2008 11:45 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

4th October 2008, 12:14 AM #2

Hi Marios

If you have not used a plane with a high cutting angle, but are able to do so, then that is the first thng to try. Since the board is small, if you have a block plane, try grinding a 50 degree bevel angle on this blade. That will give you a 62 degree cutting angle.

You could try a BD plane, like a Stanley, with a 15-20 degree backbevel. That will also give you a 60-65 degree cutting angle.

Alternately, you could just try planing across the grain, then smoothing all with a cabinet/card scraper.

Regards from Perth

Derek

-

4th October 2008, 09:38 AM #3

Thanks Derek,

I will give it a go with a back bevel. I think I might try it on a piece of scrap, I would hate to make the situation worse.

Do you think then that there is any role for those scraper planes?

regards

MariosYou can never have enough planes, that is why Mr Stanley invented the 1/2s

-

6th October 2008, 10:03 AM #4

Yes!

If you want to ease into scraper planes, try the Veritas version of the Stanley 80. These planes are easy to set up & use, & certainly save the calluses. I find they don't give quite as good a finish as a well-sharpened card scraper, but only because of my own sloth. You can force them by bowing the blade to keep them cutting longer, whereas you would stop & resharpen or at least reburnish a card scraper.

Cheers,IW

-

6th October 2008, 12:21 PM #5

Have had similar problems with this timber Marios. Over time I have collected and made a number of woodies using Japanese blades. They work well. Some have very high angles and very tight mouths also.

BUT playing with card scrapers gave me no joy at all but I did find that a sharpened blade can be used as a scraper although you want a bit of curve on the blade to keep the corners from cutting grooves.

StudleyAussie Hardwood Number One

-

6th October 2008, 08:38 PM #6

Thanks guys,

I tried the back bevel idea that Derek suggested (I had forgotten that I had already ground a few blades like this 2-3 years ago!) and that seemed to sort some big gouges but created some other ones...

Eventually I gave up and tried another card-scraper, hard work but it did work very well... it sorted the rails of the table as well as the table top and saved a whole lot of sanding.

Another problem with the card scraper is that it doesn't seem to last that long needing reburnishing after 10-15 minutes of work. It does work amazingly well but it is times like these that I wished I had a rotex!

regards

MariosYou can never have enough planes, that is why Mr Stanley invented the 1/2s

-

6th October 2008, 10:15 PM #7

Hi Marios,

imo....You shouldn't burn your fingers if its sharpened well.

The beauty of the card is the number of edges you can work...and its easy to sharpen all these edges at once. When one bluntens you flip quick as you go. Can't do that with a scraper plane or #80. Its too slow.

It feels nice when you get scraper planes going, but scraping is generally used on timbers that wear your blades quickly,,,,so you gota pull it out and reset it again a lot. After a while persisting with it, I gave up on them and just settled on using cards. scraper planes too impractical imo.

So I'd suggest, if the tearouts so deep that it'll take too long settle for the card (two at the same time switching as one gets too hot), or belt sander. If its really hard timber, consider cross grain with the belt initially to get out the tear...coarser belts that sort of thing. Or a combination....What I do often if the timbers to gnarly for planes, is belt sand then pull out my card to clean up.

The important thing I think is knowing when not to use your planes by reading grain cause one against grain pass is all it takes to have you there for much longer.

Good luck with it.

-

6th October 2008, 11:01 PM #8

Hi Marios

You will note that both Jake and I made the same suggestion to you - I said plane, he said belt sand, we both said across the grain. This will remove the tearout. We both said clean this up with a card/cabinet scraper.

I also agree with Jake when he suggests preparing all sides of the scraper blade. This will save you resharpening. Actually, 10 minutes from one on hardwood is good going. How are your thumbs?

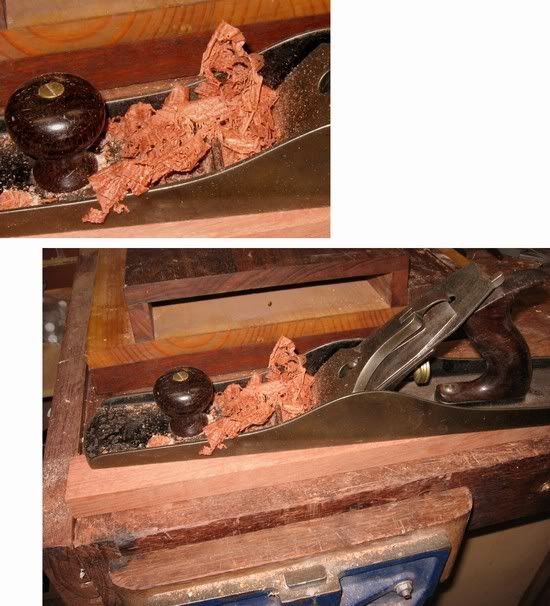

Here is another suggestion - a bit tongue in cheek, although it does work... turn your Stanley plane into a scraper plane by honing a 45 degree bevele and reversing the blade! You think I am kidding? Here is proof it works ... scraping Jarrah ...

More seriously, revisit your backbevel. Was the blade sharp? Equally on the main- and well as the back bevel? At 15-20 degrees? Mmmm?

Regards from Perth

Derek

-

6th October 2008, 11:44 PM #9

Thanks for all the suggestions..

Jake: pretty sure the scraper was sharp, I was getting full width curlies from it. I only sharpened the long sides of the scarper, next time I will do all 4... I did try the belt sander on the back of the panel and was not happy with the amount of dust it made... maybe I need a new belt sander

Derek: the plane blade was razor sharp, but I may need to close up the mouth a bit more I think. I will try the 45 degree bevel trick, but I suspect it maybe a hard plane to push at that angle . Thumbs are still working but at one stage were numb

. Thumbs are still working but at one stage were numb

Thanks again guys.You can never have enough planes, that is why Mr Stanley invented the 1/2s

-

8th October 2008, 10:05 PM #10

Ok I have had a a chance to try some of these ideas out in the shed. These are my findings....

1. I have tried the 45 degree bevel and reversing the blade trick as per Derek. This did not work for me. I probably should have done this using my 5 1/2 which has a little bit more mass but I foolishly sharpened a narrow blade (as I have a few spare of these) and tried a number 4. This maybe the reason I had no success...

2. However, the sharpened blade with the 45 degree bevel made a pretty decent scraper! So not all was lost

3. I tried to remove the big gouges with a 7 planing diagonally across the board. The blade was sharpened with a 25 degree bevel, 20 degree back bevel. This worked very well, there was some work still to be done with the scraper but a lot less.

4. Doing all this I remembered again why I got lazy and bought a jointer/thicknesser .

.

regards

MariosYou can never have enough planes, that is why Mr Stanley invented the 1/2s

Similar Threads

-

kunz scraper plane

By old_picker in forum HAND TOOLS - UNPOWEREDReplies: 3Last Post: 25th May 2007, 02:53 AM -

078 on difficult grain?

By woden in forum HAND TOOLS - UNPOWEREDReplies: 29Last Post: 11th February 2007, 04:11 AM -

Cabinet scraper or scraper plane?

By old_picker in forum HAND TOOLS - UNPOWEREDReplies: 16Last Post: 19th April 2006, 10:06 PM -

Using a smoothing plane as a scraper

By Driver in forum HAND TOOLS - UNPOWEREDReplies: 1Last Post: 8th June 2004, 05:25 PM -

Scraper Plane

By Bob Demar in forum HAND TOOLS - UNPOWEREDReplies: 1Last Post: 19th May 2000, 12:22 AM

Reply With Quote

Reply With Quote