Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 4 of 4

-

16th June 2017, 01:24 AM #1

The Howard Adjusters for LN block planes

The Howard Adjusters for LN block planes

I recently purchased a second Howard Adjuster, this time for my LN #103, and I thought it would be helpful to post a few pictures. These are available from David Eckert at The ToolWorks.

The LN #103 was the first new plane I ever purchased, about 20 years ago. It is a fabulous little block plane - although I must confess that I thought I was purchasing the #102 at the time. I should have taken along my reading glasses! The #103 is a standard angle plane (20 degree bed), which creates a 45 degree cutting angle with a blade that has a 25 degree bevel. I suspect (not sure) that the one I have has the original W1 steel. This plane is ideal for breaking edges and chamfers, where the higher cutting angle reduces the vulnerability for tearout.

The #103 is a standard angle plane (20 degree bed), which creates a 45 degree cutting angle with a blade that has a 25 degree bevel. I suspect (not sure) that the one I have has the original W1 steel. This plane is ideal for breaking edges and chamfers, where the higher cutting angle reduces the vulnerability for tearout.

A few years went by and I purchased the LN #60 1/2 low angle block plane (12 degree bed) especially for trimming end grain. I have always liked using this plane. I think the blade is A2, but I have nothing but praise for its edge holding. More than anything, this is a very comfortable plane in the hand. It is a perfect size for my hand, and I like the heft - as with the #103, the #60 1/2 creates a sense of authority for its size.

It was only when I began using the Veritas DX/NX60 block planes that I became conscious that the adjustments on the LN block planes lagged behind their ergonomics and performance. The mouth adjuster on the #60 1/2 is stiff and jerky, even when lubricated. This is Stanley's fault (they designed it). And then there was the blade adjusters .. even with the lever cap screw really loosened off, the adjuster was stiff .. very stiff. The lever cap screw needed to be slackened off completely to adjust the blade projection.

Enter Bob Howard. Bob is a fellow Aussie, a furniture maker, teacher and frequent writer for woodworking magazines of tool review and furniture builds. He designed and developed a bearing-based adjuster to replace the solid steel adjuster used on the LN block planes. I purchased one for the #60 1/2 a few years ago. More recently, I received one for the #103 (the one with the brass rear).

The Howard version has slightly larger diameter than the original. More grip is better grip ...

Here is a #60 1/2 and #103 alongside a Rabbet block plane, which has the original LN adjuster ...

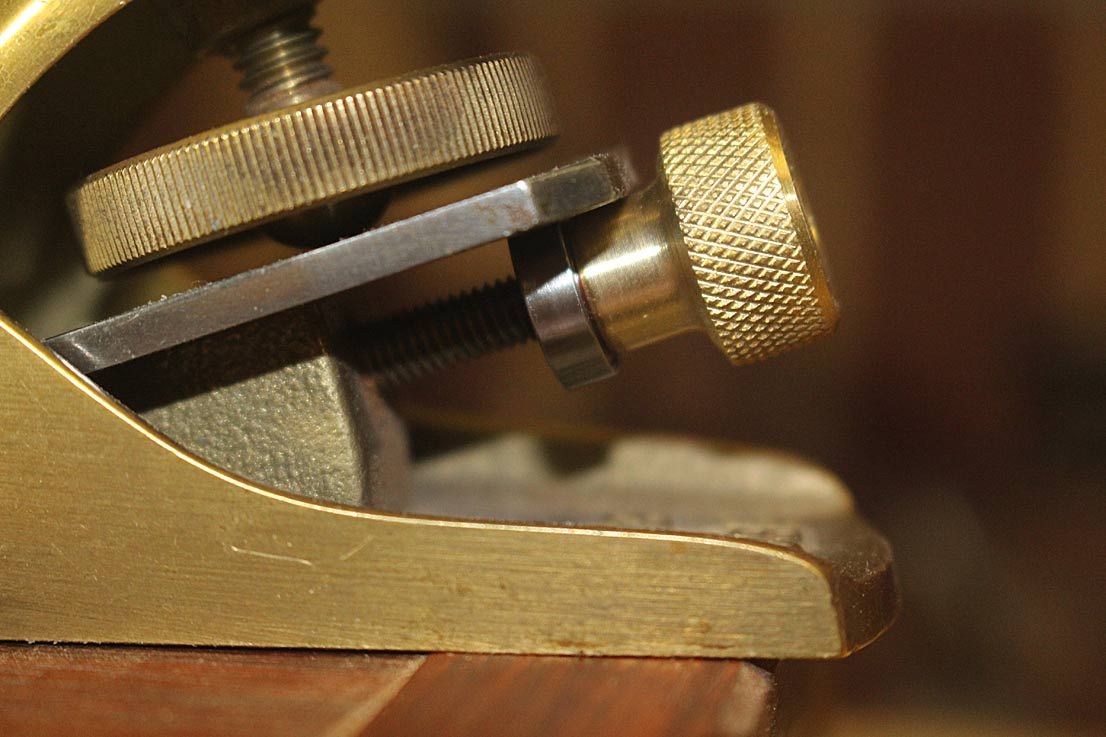

Close ups ...

#60 1/2:

#103:

So how do they work?

Firstly, they are a direct replacement. Just screw off the original, and screw on the Howard. One word of warning - important ... If you have an early version of the #102/103, then it is likely that the screw section is a different thickness to more recent versions. The current version of the screw section is the same thickness at the #60 1/2. When I received the #103 Howard adjuster, it did not fit. As a result, there are now adjusters available for the early versions of the #102/103. There has only ever been one screw size for the #60 1/2, so no issues there. Note also, that the Howard #60 1/2 adjuster also fits the Rabbet block plane, and Skew block planes (possibly also the #62 and the #164). The smaller adjuster also fits the shoulder planes.

Is it worth the cost and effort? This is difficult to answer. The planes work pretty well with the original adjusters. Add a little silicon grease, and it is a touch better still. On the other hand, the Howard adjusters are inexpensive, beautifully made, I find they are more attractive, and they do work better still. I find that blades can be adjusted with secure clamping ("secure clamping" means that the lever cap is firm enough not to move), which is what it is all about. It is not possible to turn the original adjuster with the same downforce (and I must warn you never to try that - you will damage the screw!). So, for me these accessories are well worth their cost.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

16th June 2017 01:24 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

16th June 2017, 10:05 AM #2

When I first saw Bob's little gadget, I was very impressed. Such a simple, but beautiful idea! It's the sort of thing that makes you think "why didn't I think of that!?" (You are not required to answer, btw, I already know the answer to the question.

).

).

What struck me most is that by using a bearing, it should eliminate the tendency for the adjuster to slew the blade slightly, one way or the other as the wheel drags in the engagement slot. This happens with my (home-made) shoulder plane that I based on the Record. I've been meaning to get a little bearing & make something similar to see if it will cure that annoying problem. I'll get to it some day!

Cheers,IW

-

16th June 2017, 10:11 AM #3

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

Good write-up Derek.

I agree that the LN Norris style adjusters are vastly inferior to the Veritas. I basically have to manually position my LN #102 every time I sharpen the blade. As soon as I turn the adjuster, the lateral positioning is toast. I almost sent it back when I first got it, but I was able to determine that there was nothing wrong, and it's just not a particularly sophisticated adjustment mechanism (on purpose). Good thing it's a "Set and Forget" tool. I was aware of the Howard adjusters, but, until now, it never occurred to me to get one for that plane. I'm not sure they make one for the #102, but I'm going to check now!

Cheers,

Luke

-

16th June 2017, 11:31 AM #4

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Aug 2012

- Location

- Gympie

- Posts

- 219

I think it is a brilliant invention. I have the large size one on a #62 and a #97 chisel plane. It just makes adjustment so silky.

Regards,

Ross

Similar Threads

-

Backlash adjusters

By Bryan in forum METALWORK FORUMReplies: 6Last Post: 27th June 2010, 10:38 PM -

Block planes

By Wood Chip in forum WOODWORK - GENERALReplies: 6Last Post: 23rd February 2009, 04:52 AM -

A Compendium of Block Planes: The HNT Gordon Block Plane

By derekcohen in forum HAND TOOLS - UNPOWEREDReplies: 8Last Post: 16th August 2008, 09:54 PM -

Block planes

By Pat in forum HAND TOOLS - UNPOWEREDReplies: 11Last Post: 21st September 2005, 11:34 PM

Thanks:

Thanks:

Reply With Quote

Reply With Quote