Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 9 of 9

Thread: Lee Valley Chipbreaker

-

27th December 2013, 04:12 AM #1

Lee Valley Chipbreaker

Lee Valley Chipbreaker

There has been much re-newed interest in the use of the chipbreaker in tuning a plane. We no longer hold the belief that the chipbreaker is simply to support or stiffen the blade. Indeed, the very first review I wrote was on the, then, newly released LN chipbreaker. That must have been about 10 years ago. Today the chipbreaker is seen to be an important factor when tuning a smoother.

Very recently I ordered a couple of Lee Valley chipbreakers. One was for a Stanley #3 I had restored, and the other was for a #4 1/2. There were also PM-V11 blades to go with them.

Today I had the thought to take some photos and thereby share with others my observations about this purchase. For contrast I shall use #3 chipbreaker/blade combinations from Lee Valley, Lie-Nielsen, and Stanley.

LV, LN, Stanley

At first glance the LV and LN chipbreakers are similar in shape and design. The LV is shorter than the LN.

The LV sits firmly on the blade, is a perfect match ...

... as is the LN combination ...

Both have just enough flex to pull down firmly onto the blade.

The Stanley ...

... needed a little extra bend in the body to create a tight bond. The thin steel is very flexible, too much so. What happens is that when it is set close to the edge of the blade, and then tightened, the chipbreaker will "stretch" over the position desired (if not careful, over the edge of the blade).

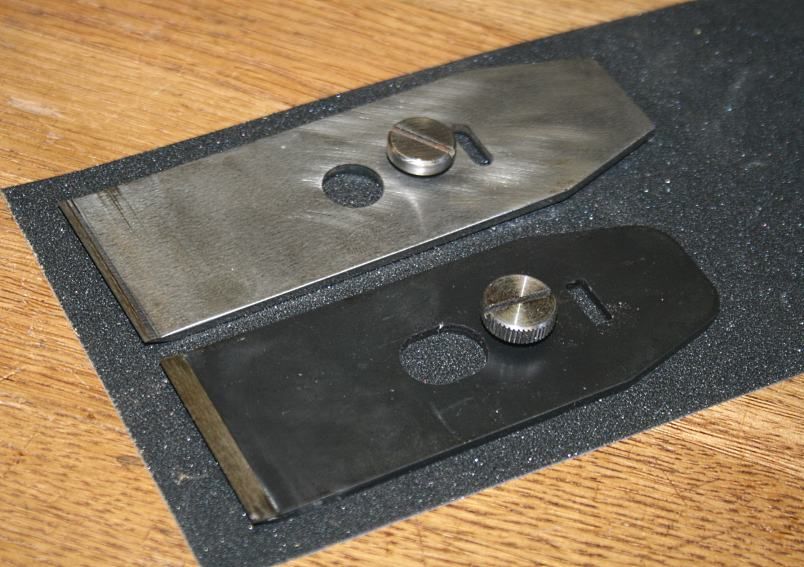

The similar designs of the LV and LN are also evident on the reverse side ..

There is a little more support at the front of the LV. This is not significant once in use as the front of the chipbreaker rests on the leading edge and not the flat. However the wide support of the LV did make it easier to balance on the medium when lapped flat (which does need to be done ever now-and-then).

Now the important side I want to show is the other side - the chipbreaker screw ...

What you will notice is that the LV screw is knurled and the LN is flat. The LV screw is also significantly thicker (The Stanley screw is also knurled, but it is the same thickness as the LN).

Why is this so relevant?

Because the LV screw can be tightened with finger tips and both the others cannot be done so as easily. Finger tightening enables the chipbreaker to be set much more easily at the edge of the blade - set it, finger tighten it, and use a screwdriver to finish when happy.

Here is the LV being adjusted ..

The other item that may simply pass by unnoticed is the hole for the frog screw. The LV is long, and this enables one to use a screwdriver blade as a hammer to adjust it rearwards.

The LN has a small round hole - very neat, but it makes it difficult to adjust in the same way.

The shorter LV and Stanley chipbreakers expose more or the blade slot, and the screwdriver blade again can be used as a hammer to tap the chipbreaker forward. The longer LN chipbreaker leaves open none of the blade slot open, and cannot be used to adjust in the same way (refer to the initial photo for illustration).

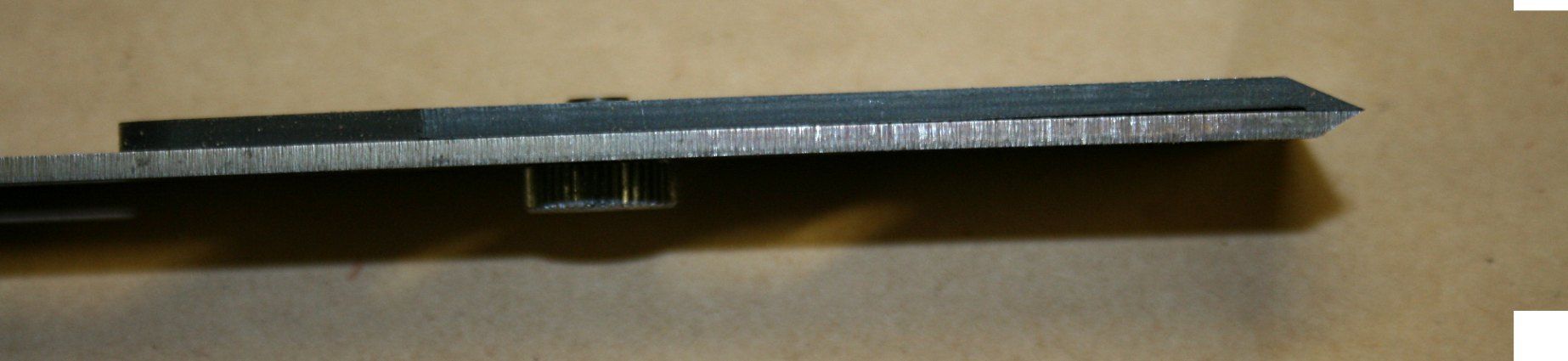

It is relevant to note that the front edge of the LV and LN chipbreakers both angle at 25 degrees. This is too low for Bailey-type planes with a 45 degree bed. A secondary microbevel of about 75 degrees needs to be honed. This is easily and quickly done freehand. More on this in further article.

In summary, the Lee Valley chipbreaker is excellent and, in my opinion, the better design of the three.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

27th December 2013 04:12 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

27th December 2013, 08:47 AM #2

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2009

- Location

- South Africa

- Posts

- 950

There seems to be a lot less usable blade on the LV, due to the slot extending much further down the blade, which appears to be as a consequence of the chip breaker being shorter.

-

27th December 2013, 02:34 PM #3

Hi Colin

It should be the same amount of usable blade. It is only the rear of the chipbreaker that has less area in the LV. And in my opinion this is a good thing (for adjustments).

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

27th December 2013, 02:44 PM #4

Observant

I hadn't picked up on that - there's quite a difference there.

I hadn't picked up on that - there's quite a difference there.

I wonder if LV would suggest being a pm iron there was at least equal working life there?

But I would also assume that the irons will be the same shape, regardless of the metal type ... so if both they and LN have A2 blades side-by-side I think your point would be quite valid.

Cheers,

Paul

-

27th December 2013, 02:49 PM #5

Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

27th December 2013, 03:58 PM #6

Hi Derek ...

I was taking Colin's comment to be about the distance *on the irons* between the cutting edge and the bottom of the circular keyhole.

Cheers,

Paul

-

27th December 2013, 04:14 PM #7

Oh so! My mistake. Sorry. Still I very much doubt that it is an issue - certainly a comment at a tangent to the topic here, which is a chipbreaker and setting it up.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

27th December 2013, 05:00 PM #8

I'm sure Mr. Hock and Mr. Clifton are feeling a bit neglected here...

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

28th December 2013, 12:25 AM #9

We cannot have that Vann

Here are a few more chipbreakers.

First the Clifton. This comes out of my Stanley #51 (shooting plane) where it is paired with a Smoothcut laminated blade. The Clifton uses the Record Stay Set design, which has a removable toe (to facilitate easier sharpening). Frankly this design is a royal pain in the youknowwhat since the toe is not securely attached and tends to fall off. It is held securely by the lever cap. However this arrangement does make it more difficult to adjust close to the blade edge. After the umpteenth time that the toe fell off, I epoxied the two parts together!

The chipbreaker is a similar thickness to the LN and LV.

This Hock chipbreaker comes from a smoother I received from Jim Krenov, where it is paired with a Hock blade. Of interest, when the plane arrived the chipbreaker was set 1/16” from the edge of the blade. The mouth is tight. The plane had been used. From this I would conclude that Jim did not set up his planes with the chipbreaker.

Here are Clifton and Hock chipbreaker screws flanking the Lee Valley …

The Clifton screw is identical to the Stanley – having stated this, it may very well be a Stanley as it has been so long. However, in the deep recesses of what is left of my brain is the memory that the Clifton screws used a different thread to Stanley.

The Hock screw is slightly thinner but does not feel so. It is second to the LV to grip. The reason for this is that it, as with the LV, have coarse knurling. The knurling on the Stanley and Clifton is very fine, giving some but not as much grip as the LV and Hock. The LN has no knurling, and the smooth circumference makes it the hardest to grip.

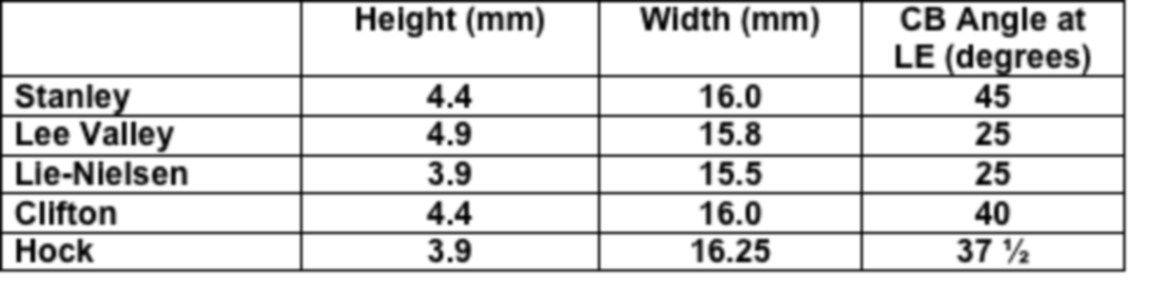

Here is a summary of screws dimentions:

The differences in screw size do not look great on paper. However add in coarse knurling and the little extra height of the LV is very noticeable and makes it stand out. The coarse knurling on the Hock brings it in second. The Clifton and Stanley come in equal third, with the LN bringing up the rear.

And here is the answer to the question that will be asked: the LV screw fits the LN chipbreaker.

With regard the chipbreakers, per se, it can be seen that the leading edge angles of the LV and LN, and to a lesser extent the Hock, stand out as the two that really would benefit from a higher secondary microbevel. The Clifton and Stanley are within the range found by some to be acceptable.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

Kanna chipbreaker question

By fissionchips in forum JAPANESE HAND TOOLSReplies: 9Last Post: 13th May 2013, 12:12 PM -

Chipbreaker boring bar

By morrisman in forum METALWORK FORUMReplies: 5Last Post: 23rd March 2012, 11:31 AM -

What difference a chipbreaker

By mat in forum HAND TOOLS - UNPOWEREDReplies: 29Last Post: 23rd June 2010, 06:38 PM -

A chipbreaker study

By Groggy in forum HAND TOOLS - UNPOWEREDReplies: 2Last Post: 25th March 2008, 06:59 PM

Likes:

Likes:

Reply With Quote

Reply With Quote