Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 9 of 9

Thread: Molding planes

-

26th June 2015, 11:25 PM #1

Molding planes

Molding planes

I realised something today when I was using a molding plane and that's the depth of cut is determined by the amount of protrusion of the blade, so the less the blade is protruding the quicker it will bottom out and the more it's protruding the deeper the cut will be. So why is that?

-

26th June 2015 11:25 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

26th June 2015, 11:50 PM #2

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2010

- Location

- US

- Posts

- 3,130

Are you talking specifically about hollows and rounds?

-

27th June 2015, 01:27 AM #3

-

27th June 2015, 02:06 PM #4

no but profiled moldings

-

27th June 2015, 04:28 PM #5

why is it so ??

I don't have a clue!! Your going to have to explain it a bit better S1

Contemplate this I bet Julius could help here .

I bet Julius could help here .

-

27th June 2015, 10:32 PM #6

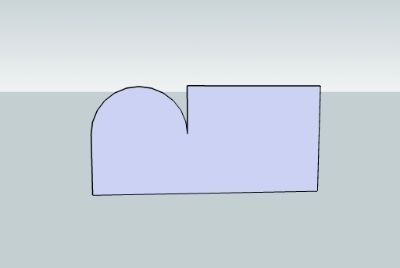

Moulding planes cut to a specific depth and stop cutting as a result of a built-in depth stop, and not because of the depth of the blade.

There is a raised section of the body that eventually stops the blade cutting deeper ..

This is not a feature of hollows and rounds, only beading planes and complex moulding planes.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

28th June 2015, 01:08 AM #7

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2010

- Location

- US

- Posts

- 3,130

If it's a complex moulder, you may have some parts of your iron that are not sharpened evenly with the profile. If the cut is lessened they may not be cutting, which would act as an unintended depth stop.

-

28th June 2015, 09:14 AM #8

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Feb 2015

- Location

- Hobart

- Age

- 77

- Posts

- 649

auscab

......and one and a half glass of milk

yvan

-

28th June 2015, 09:37 PM #9

yep ! thats what I realise every now an again too. Finally, I've found someone who gets me.

I would have thought….

- the less the blade protrudes

- the slower the cut in the wood it forms which is-> bad….bad because if your've got a lot of moulding to do that must match up, a sharpen up midway, can mess with the joinery. Far better for the blade to hold up all the way through.

- a finer more polished finish is created -> good but not really as important as it sounds because only one tear is enough to stuff it.

- the harder it is with some profiled blades to sharpen so they match well to their soles. (can be painful imo) ie. you can get a good cut even if the sharpen up isn't perfectly the same as the sole if its sticking out heaps.

ie. Best results I get is to buff sharpen blades which will yield sharper results than stones…..set the blades as coarse as possible (so you get all the profiles done quickly before it bluntens) whilst retaining control and a good finish.

Sorry, just had to exercise me communication skills …despite the feeling that section1's question is a piiiiiisstake. Well, not sure. Maybe 90% chance. 80% ?

Similar Threads

-

Where to find molding planes

By section1 in forum HAND TOOLS - UNPOWEREDReplies: 24Last Post: 25th December 2012, 01:57 PM -

A Note on Molding Planes With the Owner’s Mark EEL.

By TobyC in forum HAND TOOLS - UNPOWEREDReplies: 1Last Post: 21st August 2012, 03:10 PM -

Molding

By Sokolic in forum WOODWORK - GENERALReplies: 2Last Post: 1st May 2008, 06:55 PM -

Molding

By stymie222 in forum WOODWORK - GENERALReplies: 0Last Post: 28th September 2006, 09:36 AM

Likes:

Likes:

Reply With Quote

Reply With Quote