Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 31 to 45 of 77

-

30th November 2007, 03:19 AM #31

-

30th November 2007 03:19 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

30th November 2007, 03:31 AM #32

Ahh Gerard (Conger), welcome to the Ubeaut forum.

Ladies and Gentleman, you will need to watch his keen (or is that pickled?) Irish wit. You have been warned!

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

30th November 2007, 07:26 AM #33

Senior Member

Senior Member

- Join Date

- Sep 2007

- Location

- Finland

- Posts

- 360

Hello Derek

So very much thanks about the trouble you saw here. It seems this summary of the particular thread distilled the essence of the debate in question.

May I comment on something, in a friendly manner or course?

During the debate, there was referred to two independet actual plane reviews, where yours was concluded as a positive opinion, and the one involving Our Lady of the Cornish Workshop concluded as a polite opinion with certain reservations concerning the irons.

Then there were Jake's comments, based on raw experience of planes and their tuning into similar purposes, but not on the Veritas plane itself. But when these different models of planes are seemingly able to perform similar kind of results, his opinion on the usability is not ignored because it is really based on the top class experience, too. Such guys often know what will happen without even starting up the thing. But there is risks in such opinions, too. One particular tool or method may suddenly appear with unique combination of properties, where just guessing is not quite enough. In this case, I am not able to comment that, only bring up the need of tapered blade profiles in other uses.

A bit distant analogue maybe, but it kinda resembled a situation where the other gentleman compares different engine options for a sports car for maximum driving comfort and sophisticated car experience, but the other gentleman would rather emphasize the operations considering general tuning of suspension and tyre selection for a forthcoming rally race, despite the engine selection. (as a finn, I'd say to pick up both )

)

But like said, I am not worth to evaluate the contents of the debate, only able to read and learn something, before I have own and used something like that extensively.

Those reviews, shop notes and arguments from both of you gentlemen are one of the major reasons why I am happy to spend time here in WWF. Considering for example planes and planing itself, I feel this forum has concentrated into essence of the their usage instead of continuous branding and puffing. I sincerely thank you and WWF for that.

If coming back to the Veritas plane, I am tempted to ask if you would truly recommend to buy it. I will not make such a question, because that kind of question would actually violate the original spirit of the concept of review.

But I would gladly appreciate comments on which one of those combination planes would be the most usable for a gentleman who has already some years of experience in planing wood with handplanes. So far I have done my grooves and dados with a power router, and I wish to abandon it completely. But if I had a combination plane, I think I would be able (with my current access to tool making gear) to tune up anything into usable form, but still I'd like to purchase something readily good. I would say I am after the comfort of use, because I am just a free time woodworker.

Derek and guys, thank you again.

kippis,

sumu

-

30th November 2007, 08:18 AM #34

On reflection, it seems to me that the angled blade is important, but, in perspective, perhaps not as important as other features and settings such as the fence. A new user would gain more from focusing on keeping the unit square in use than fiddling with square or tapered blades. In fact, given the cost of a trimmer and its ease of use, a neophyte would be more productive with a trimmer; as stated previously.

That said, if someone is determined to neander down the road, prioritising the skills and applying them in that manner would save some effort. For example, a new user may be misled that it if a blade is tapered a superior result will be achieved and neglect the basic requirement for keeping the plane square.

I'd be interested to see a prioritised list of skills/adjustments because a lot of them have little benefit to the user unless other, more important, skills are mastered first.

-

30th November 2007, 10:52 AM #35

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,800

Firstly, thank's Derek for your comprehensive post about these planes.

I know zip about these planes or their blades so I will confine my comments to what I know. I know Derek is a very quantitative guy so hopefully he will take these comments constructively

There are 51 posts in this thread. Derek and Jake posted 26 times. Of the remaining 25 posts, 3 were moderator statements and the majority of the others were comments or questions ie neither supportive or negative. Which ever way you look at it, Jake is not a 1% objector.

I also know something about geometry and image analysis so I feel I can comment on the image of the groove profiles.

In this image Lines A and B are parallel.

Line B is not parallel with C, this could be due to non square cutting or image parallax.

Lines C, D, and E, and the line running along the bottom of the top groove are parallel.

From the previous statement it is reasonable to infer

- that the edges of the block and the associated face are also parallel

- the line running along the bottom of the top groove is parallel and so is the actual groove bottom

- the bottoms of the bottom grooves are not parallel with the bottom surface of the block

Lines F, G, H and I are all drawn parallel. From these lines one can say

- the LHS of the top groove is square to the top surface and groove bottom, but the RHS does not appear to be square.

The sides and bottoms of the bottom grooves appear to be neither square or parallel to their appropriate surfaces

If the plane used to make these grooves "plough a fine groove", then this image clearly does not show that.

-

30th November 2007, 11:37 AM #36

Bob

Thanks for the effort - but there is a flaw in any such analyses.

Firstly, the top groove is the one I presented as data. The other grooves were just practice. I cannot even say for sure which plane was used to plough them. What you see in those lower grooves are the ends only, not the grooves per se. You are judging the ability of the plough to cut straight on this poor work by me. When I presented the "data groove" I was showing the internal structure for comment, not the extenal ends.

What I should do is cut the board in half and then look at the squareness of the groove as it is in the centre of the groove.

I might also cut a few more and slice them up longitudinally.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

30th November 2007, 11:59 AM #37

I'll post some pictures later tonight (my night) of some blades and make observations about them--as well as a few other comments.

For now, let me simply add that nit-picking at a series of grooves for being square is itself not a good way to judge the tool in question--only the user ability to perform with the plane for its intended purpose and the person's care level when they were created.

fwiw, creating a series of grooves that close together is itself made the more difficult due to the side walls wanting to flex. It takes a pretty steady hand to do this and the person has to actually want to do it to obtain better results (even if it isn't photo induced).

I really think a mountain is being made from a molehill. Most of this is purely academic, which is something of interest to me but has to be a bit boring for some.

Take care, Mike

-

30th November 2007, 12:39 PM #38

I only have a few thoughts to add:

- Alf added the following on her blog, which I think is interesting, and adds to the discussion:

"for the record I did try an old cutter in the LV and while it did confirm me in my opinion that the cutters were causing some problems, the difference wasn't enough to reconcile me entirely. I wish it had, 'cos my default state of being is to like all ploughs and combis and it bothers me that I don't!" - I prpose to take up Jake's challenge. Anyone care to join me?

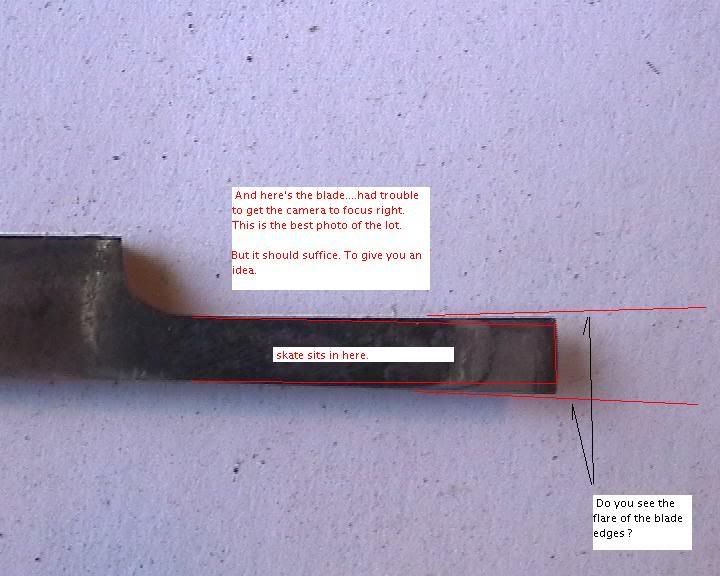

I propose to get out two 1/4" cutters with relieved edges that fit my Record 043 and grind new bevels on them and then hone them. I will then test them one after the other in the 043 on a piece of scrap to satisfy myself that I can't tell them apart and then rehone them.

I then will take one and grind about 0.5 mm off the sides from the end up to about 10mm from the back of the bevel and then grind the flare. I will then try the blades out in the 043.

I will report back what the result was, when I get round to the experiment. I might be able to do it this weekend, but I may be put on parental duties...... - If there is less binding or if it otherwise makes for better performance, what we will need to do is to convince someone like Paul Williams to make flared cutter replacement blades!

Cheers

Jeremy

If it were done when 'tis done, then 'twere well it were done quickly

- Alf added the following on her blog, which I think is interesting, and adds to the discussion:

-

30th November 2007, 12:49 PM #39

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,800

Fine - but I do not recall reading this anywhere in this thread.

Sure but anyone seeing the ends would have to wonder why they were like that. Hopefully the way I wrote my post suggested that I was not judging anyone or any tool in what I said - I was judging the image as presented and agree that the grooves a little way further in could be better than the ends.

That would be good. Also take the photo completely groove end on so it won't matter if the board is not cut square.

Cheers

-

30th November 2007, 03:21 PM #40

Ok, the camera is not cooperative (driver on the computer I think) and cannot download the pictures I took. I tried scanning the irons and one cannot see what needs to be illustrated.

In lieu of the detailed photos, I only have the older photo below--which is near pointless for, well, the point.

That is my wedge-arm plow. It's probably because I know it's there, but the iron in the photo tapers slightly from the face (the bottom in the photo) to the back that has the groove that rests upon the skate. That set of irons does not taper along the length of the iron from the cutting edge to the shoulder of the iron.

I also have a continental plow very similar to the one in Whelan on page 127, Figure 7:25. That plow has German irons. Those irons, like the one above, is made from laminated (laid on) steel. The face of the iron is made from a harder steel than the remainder of the iron.

These German irons taper heavily in cross section (trapezoidal) and are much thicker than the one above. They are also older and are less refined in their appearance. 4 of the 8 taper in width along the length from the cutting edge to the shoulder. 4 do not. From looking at them, the ones that taper in width along the length, are simply a byproduct of grinding (manufacturing) them. The taper is uneven and even the amount of trapezoidal taper may not be the same from one side to the other at a given point up the blade. Vagaries of manufacture. So I don't think the longitudinal taper is purpose ground. The other option is that it is the other 4 that were not "properly" ground.

The body of the continental plow cannot be used. Too full of worm holes and is nearly falling into dust day by day. The irons is why I bought the plow and one day will recreate the body in order to use them. Hey, I like plows and simply have a weakness for the things!

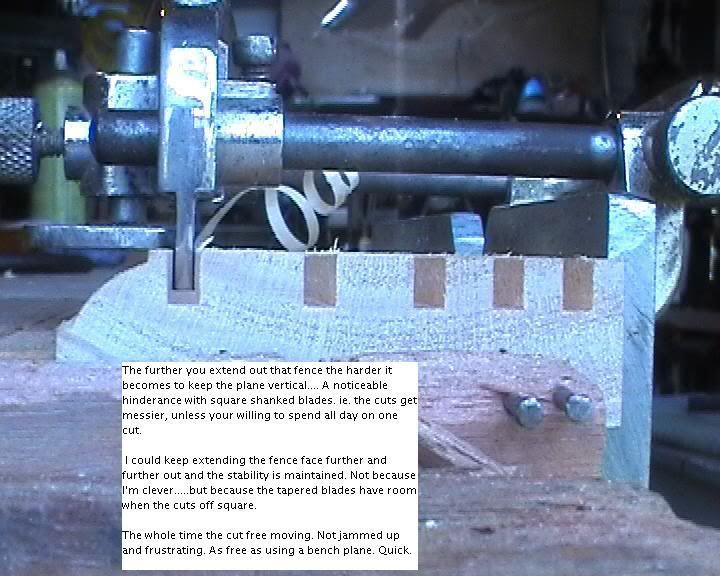

So what? I don't know. In a PM to Derek I mentioned that I think trapezoidal shaped irons while reducing drag would have a greater impact on wider blades. With a narrow blade, there is little resistance anyway. What resistance is added with an iron of 3/8" or less is to me insignificant. As well, with a narrow iron there is more of a balance issue. For that, a deeper axillary fence is a bonus, an aid to helping the user keep the plane plumb to the board receiving the groove. Don't believe me? Groove using an 1/8" or 3/16" blade. Move up in width using the same style of blade. Resistance increases greatly if the iron is not at least trapezoidal in shape.

This axillary fence should rise as Jake says to the top edge of the board when the plane is setting down in the deepest groove one is cutting. At least if the board is overhanging the edge of the bench. Myself, I do one of two things. Either I align the board (if a short enough piece is being grooved) to the front edge of the bench so the fence of the plow rides down upon it as the groove deepens. But my vise gets in the way if the board is very long. In that instance, I raise the stock up on another board, placing the board being grooved aligning both boards' near edges, hold both boards with an end stop at the far edge of the bench and using either a holdfast or a face clamp, secure them to the bench top. That allows the fence to ride down onto the bottom board.

None of the methods for shaping the iron nor axillary fences for helping to keep the plow plumb matter in the sense that none of those things ensure a given result. It still takes using the things to develop a sense of plumb. One can tilt the plane regardless of fence. One can still end up with bruised shoulders, out of square grooves, or rough bottom finish. In most cases, these conditions do not matter except perhaps a wounding to the pride of the creator. Most times, the panel will still fit. The grooves align if/when the boards are joined or mitered.

So what about the Veritas plow in this review? Don't like it? Don't buy it. Don't believe it works well enough or think it is too expensive? Don't buy it and instead buy a vintage plow. Don't like the iron shape on this new plow? Or you buy a vintage plow that doesn't have tapered irons? Taper them. It ain't no big deal to spend 20 minutes tapering a few blades. The taper (both trapezoidal and in length) do not need much relief to provide efficacy.

Oh, one more thing. As I refurb a plow iron, I sharpen the sides where the sides meet the iron's face right near the cutting edge. Just a bit of rubbing on the sharpening stone. Those leading edges should be considered part of the cutting dynamic. I usually round the back edges and simply "break" the sharpness above the leading portion of the face edges.

What is more important to me than what plow plane one buys is that more people try using plows for grooving. It's a sane approach to such a simple task.

Take care, Mike

-

30th November 2007, 03:57 PM #41

I beg your pardon ?........Your making that up. where have I agreed to that. I actually said the opposite. Back there I said that you won't find a more objective person than myself. And its true. If I'm wrong I"LL SAY AS MUCH.

I am pushing the point, simply because I know how strong a point I have. Its proven from experience Derek. Else I wouldn't bother. Why would I bother ? Actually I shouldn't probably bother at all. I'm really beginning to think there really are better things to do with my time.

Well, the jury is clearly out with me because I've been doing it at work and home for the last 2 years. And if the concept didn't work I would have ditched it, and never brought it up. you guys can be impossible.Indeed he has a vested interest in proving others wrong and his own views right. Whether he is correct or not - the jury is still out in this regard so I have offered to evaluate this issue to help clarify these matters - the fact remains that the Veritas ploughs a fine groove as is.

I'm not working for 2 weeks due to care for my ill wife, so I'll have time to hit the shed here and there. So if you want me to take photos of anything in particular to try and catch me out...or whatever.... I will. Don't know why, cause its like hitting my head against a brick wall with some of you. I'm not getting paid for it. All I get is resistance to help I'm actually trying to give.

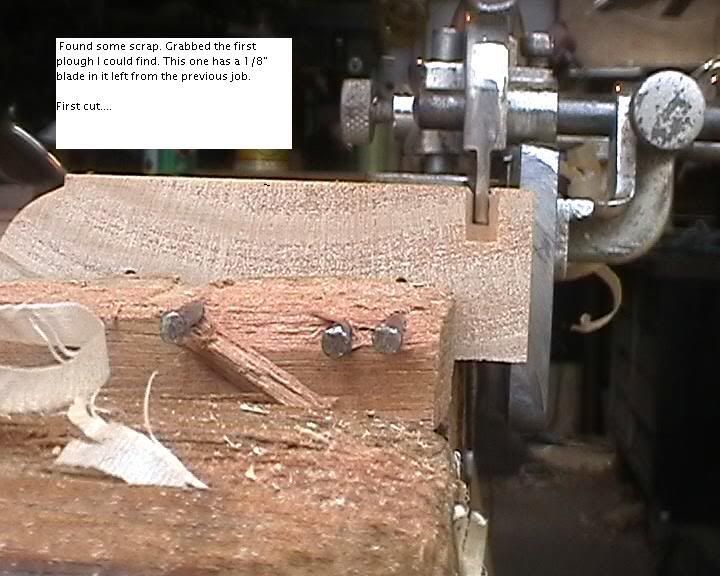

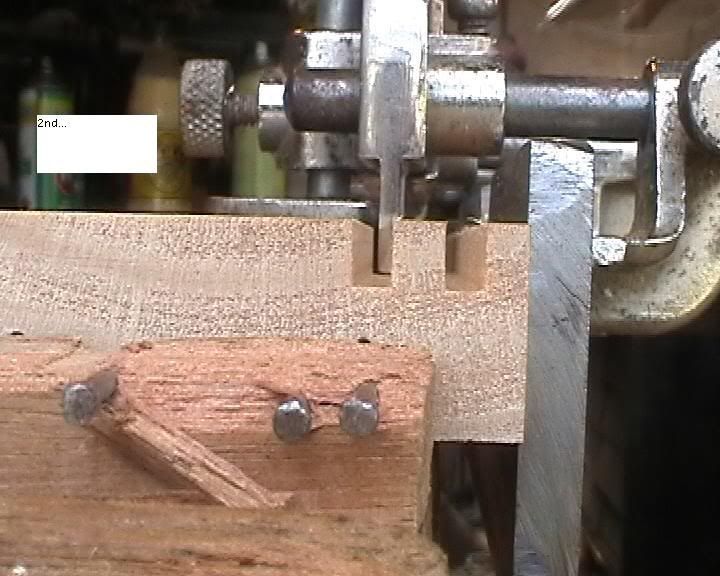

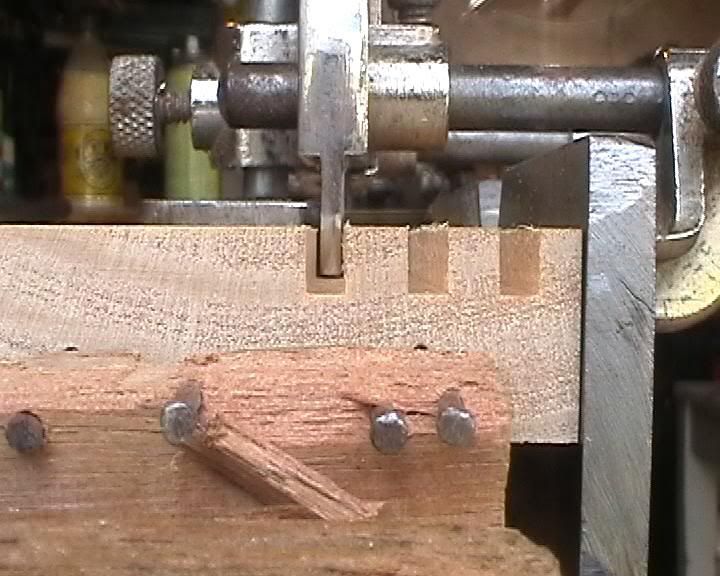

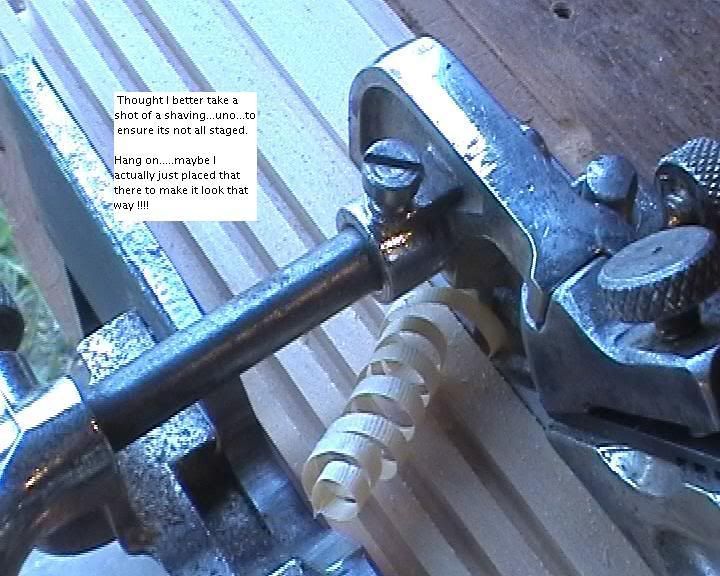

ANYWAY, here we go again....as if I haven't splashed enough photos already (have you even checked out that link I gave in my post back there at all Derek?)

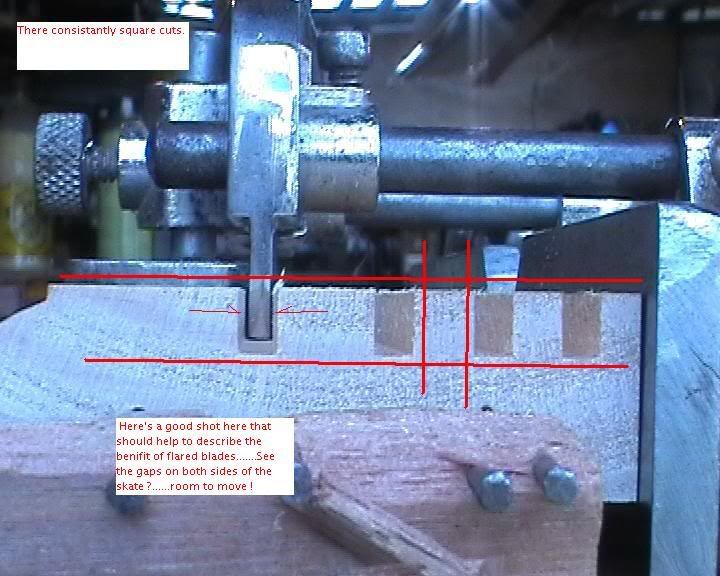

Those cuts (parallax error and all ) are as good as the trimmer jobs at work. Each cut took, I don't know, 20-30 seconds to do. As you would expect from effortless planing. I can wait the plane heavily with a lot less concern for keeping it vertical. I can take a much coarser cut to speed it up you see.

) are as good as the trimmer jobs at work. Each cut took, I don't know, 20-30 seconds to do. As you would expect from effortless planing. I can wait the plane heavily with a lot less concern for keeping it vertical. I can take a much coarser cut to speed it up you see.

Yes, there are plenty of factors that determine success with a plough. But if you took 2 blokes, each equally experienced, each with tuned planes ready to go, with the only difference being that one of them is using a flared blade.....and they had a race. I can tell you straight away, who will kick the other guys ???? both in terms of quality and speed.

I can tell you straight away, who will kick the other guys ???? both in terms of quality and speed.

The concept I think is really quite simple and makes sense if you visualise it, which confuses me even more why there's so much resistance to it.

The flared concept is also directly applicable to moulding plane cuts etc etc. It opens up all sorts of options. Thats how strong a point it is.

-

30th November 2007, 04:52 PM #42

Times like this I wish I had a plow plane so I could just go and try it myself

I have to say though, the theory sounds fine and the results look crisp and square.

-

30th November 2007, 04:52 PM #43

You're talking to someone who uses a table saw for that sort of thing, but those grooves look pretty neat I must say. Almost makes me want to go and buy a plough, as if I didn't have a million other things I could do with the money.

"I don't practice what I preach because I'm not the kind of person I'm preaching to."

-

30th November 2007, 05:16 PM #44

If I may comment,

I add my thanks to Sumus to the contributors of this thread. As a novice to all aspects of hand planes the information you provide is terrific.

Derek your review demonstrates the function, design and quality of the Veritas product exceptionally well and as an owner of a veritas plane I am confident when I graduate to a plough I will be satisfied.

Jake your arguement regarding taper of the blade makes sense to me and would I think add to the planes performance. Looking forward to others having a go and their comments.

It's interesting how power tools can provide an entry to woodworking when the newbie merely wants to make stuff but quality handtools with sharp blades and the know how to use them provides another level of appreciation.

Thanks again

Mike

-

30th November 2007, 11:07 PM #45

Senior Member

Senior Member

- Join Date

- Sep 2006

- Location

- Bookham, Surrey, UK

- Age

- 79

- Posts

- 137

Hi Jake,

Sorry to come to this a bit late. As always, your thinking is sound and your results speak for themselves

Not a lot more to say really, except "Thank you" for going to so much trouble to explain to people how to get the best out of these planes. Your efforts are much appreciated

Keep up the good work.

Cheers

Paul

Similar Threads

-

Homemade Plane Blades from M2 HSS for Wooden Planes

By thumbsucker in forum HAND TOOLS - UNPOWEREDReplies: 351Last Post: 27th July 2009, 04:52 PM -

D2 Plane Blades - Batch Order 02

By thumbsucker in forum HAND TOOLS - UNPOWEREDReplies: 259Last Post: 16th November 2008, 08:34 PM -

removing stuck blades from old planes

By bannock in forum JAPANESE HAND TOOLSReplies: 13Last Post: 31st January 2008, 04:29 PM -

The Veritas Small Plow Plane

By derekcohen in forum HAND TOOLS - UNPOWEREDReplies: 18Last Post: 1st December 2007, 11:30 AM -

Putting wooden plane blades in Stanleys.

By JDarvall in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 18Last Post: 30th November 2005, 08:29 AM

Likes:

Likes:

At the risk of re-igniting WW3, I will offer the following:

At the risk of re-igniting WW3, I will offer the following: