Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 9 of 9

-

16th August 2013, 05:55 PM #1

RASPS - COATED verses UNCOATED - simple test comparison

RASPS - COATED verses UNCOATED - simple test comparison

For some time I've been curious to what practical difference/s there might be in an uncoated rasp verses a coated rasp. The three reasons for having a rasp coated are:

- A claimed "sharp" life of up to 4 times longer than uncoated (it'll be some time before this can be determined

)

) - Less clogging

- Rust proofing (or at least a very strong inhibitor)

For this test I selected the following:

- Cabinet Maker's 10 inch stitched at #9 grain uncoated, and brand new out of the box

- Cabinet Maker's 12 inch stitched at #9 grain Sapphire coated, has had a very moderate amount of use.

- Half Round 10 inch stitched at #12 grain Sapphire coated, has had a very moderate amount of use.

The main focus of attention was the two CM rasps (because the Half Round is a finer stitch). Whilst the two CM rasps are both #9 stitch they are slightly different in profile width. However, they both have 27-8 teeth along each diagonal row. This means the the wider 12" rasp has slightly less densely populated toothing, with the same number of teeth hitting the wood over a slightly greater surface area. In other words, it would be anticipated that would be a little less efficient because it is being asked to address a larger surface area.

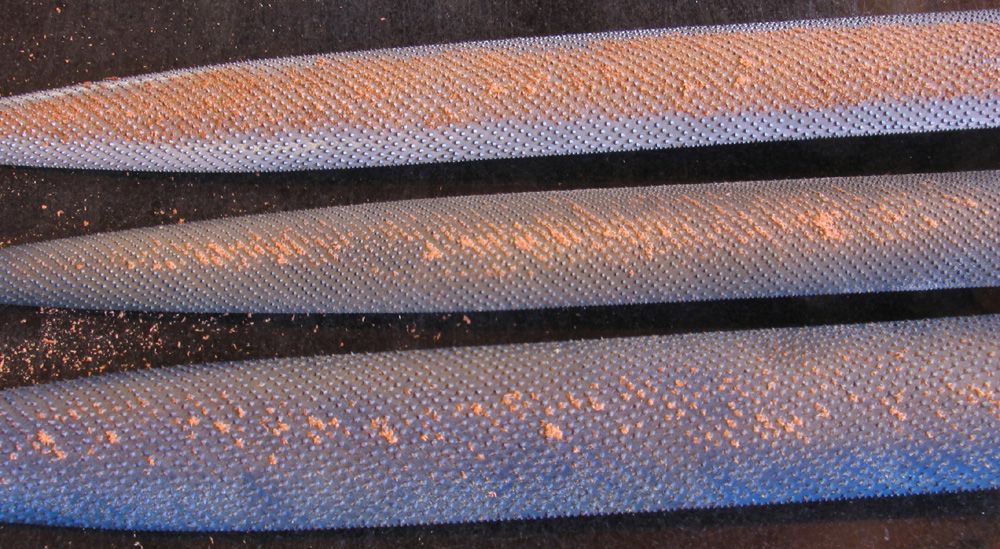

The three rasps - LEFT is 10" Cabinet Maker's #9, MIDDLE is 10" Half Round #12, RIGHT is 12" CM #9

The slight discolouration to the coated rasps (blue) is from previous cleaning with a solid brass brush (they are essentially brass plated now).

RESULTS:

Each rasp was given 30 strokes across a very dry piece of She Oak. Left to right in the same order as above.

It can be seen that the larger coated rasp (right hand result) removed a slightly greater amount of timber (more dust). I attribute this to the its larger profile, even though the number of teeth hitting the timber would be slightly less - not all the 28 teeth per row were in contact with the timber because of the radius of the rasp face.

CONCLUSION:

I'd have to say that I didn't notice much difference in the "feel" of them - the uncoated rasp had a very slightly sharper feel, and the audible tone was a little different.

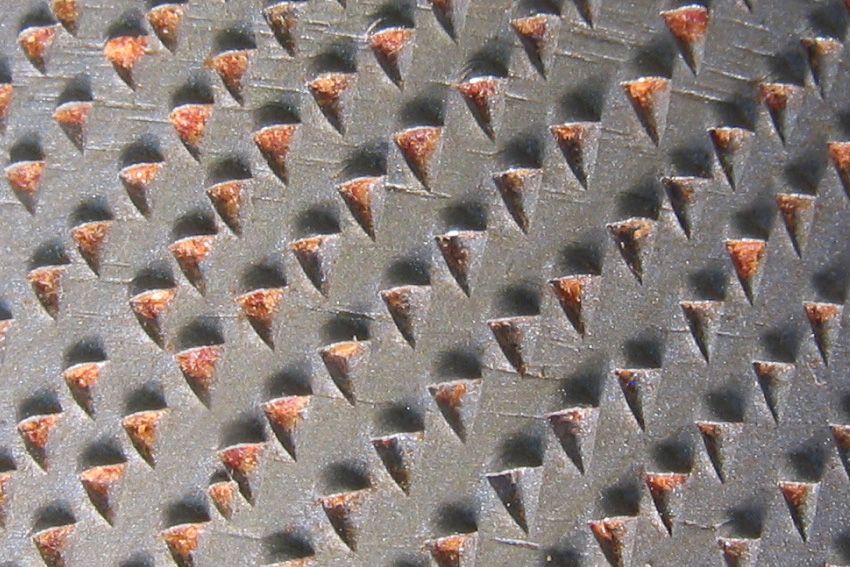

The most obvious visual difference was in the amount of material left clinging to the rasp (clogging). The uncoated rasp at the top of the next pic had the most amount of material left on it. This could have been a result of the very fine oil that had been factory applied to it, but one would expect that to be removed after about 10 or so strokes (and there were 30).

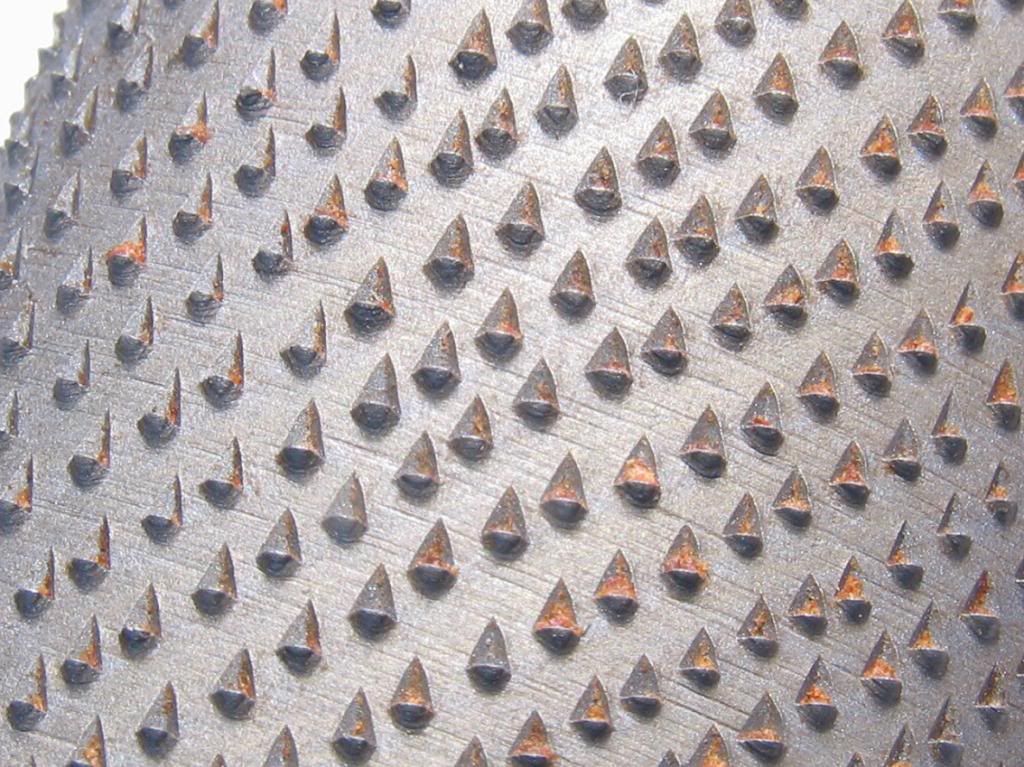

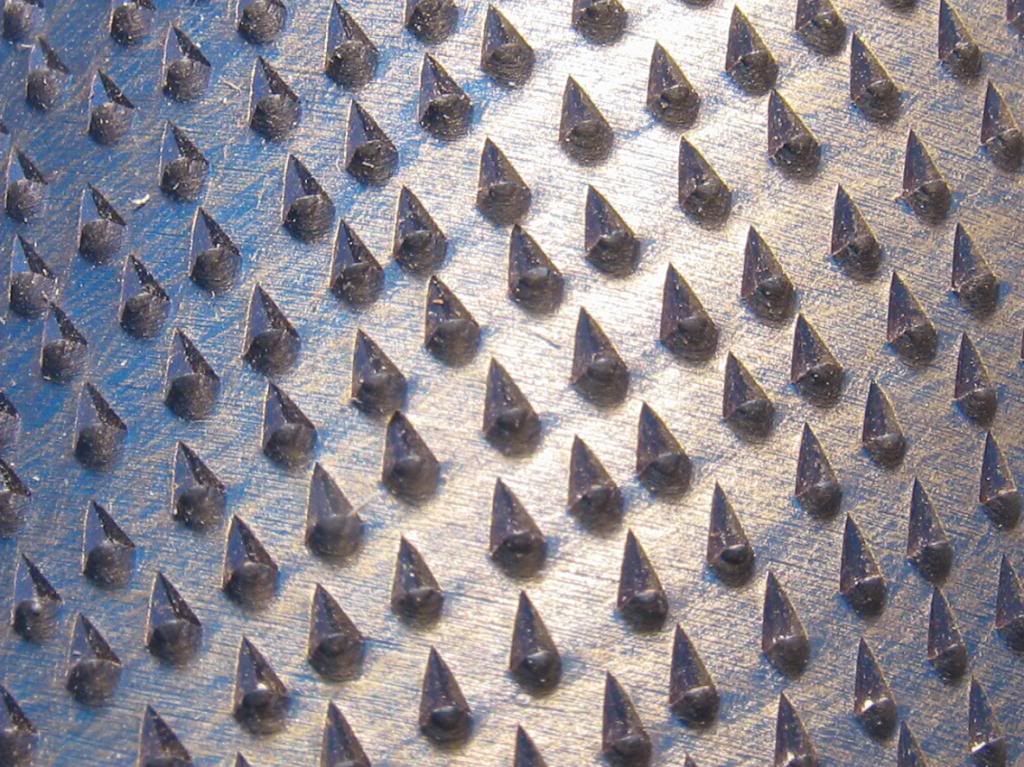

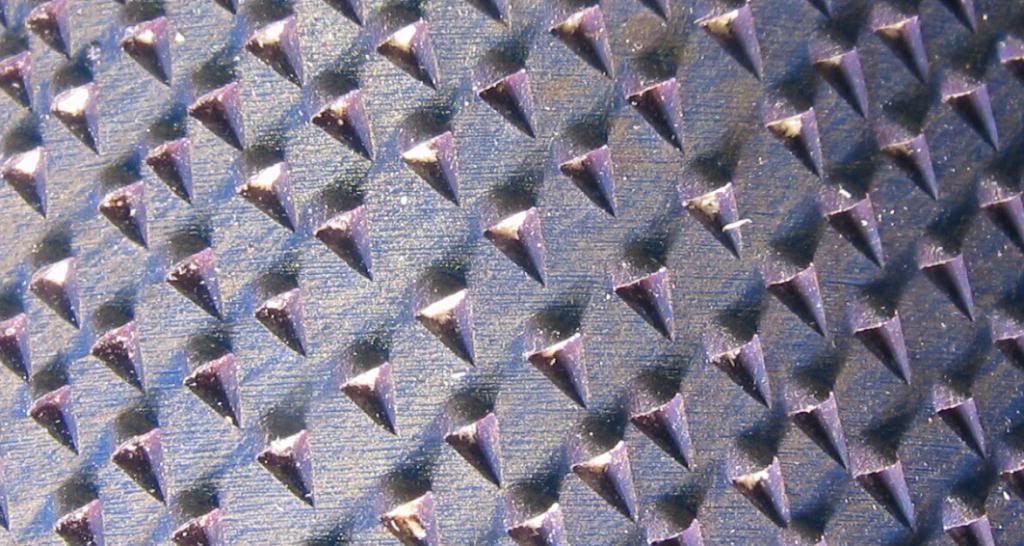

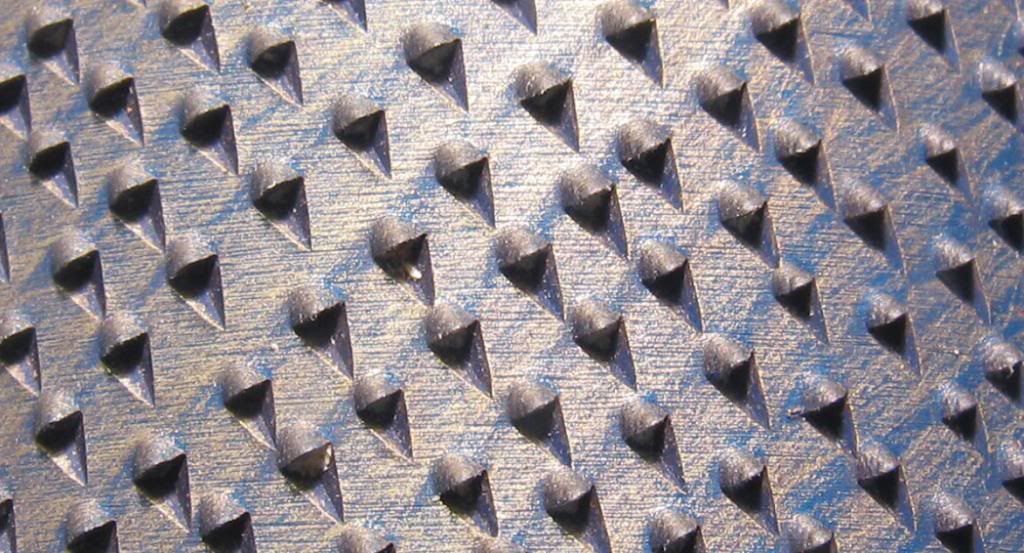

SHARPNESS OF THE TEETH OF THE TWO CM RASPS AFTER CLEANING:

A visual inspection with an 8x and 30x loupes shows that there is a measurable difference in wear between the two rasps. On the uncoated teeth there were shinier ridges where the grey coating from the normal manufacturing process (pickling) has worn away. This grey coating is not very hard, and has a slight rust inhibiting characteristic. What can be seen though (with the loupes, more than the following pics) is that the teeth of the uncoated rasp have already started to round over. The coated teeth looked like new (and not forgetting that they have already seen some service, compared to the brand new uncoated rasp).

1a. Uncoated

2a. Coated

1b. Uncoated

2b. Coated

1c. Uncoated

2c. Coated

This would indicate that the claim of an up to 4x sharpness life for the coated rasp does indeed have a solid basis in fact.

After the counted number of strokes I continued with a bit more rasping, swapping backwards and forwards between the two CM rasps and I could only detect a very marginal difference in performance and feel - not worth worrying about.

This leads me to these overall conclusions:

that the difference in clogging is pretty obvious, and may result in more regular cleaning being necessary for a given number of strokes

that there is a negligible difference in performance between coated and uncoated

the extra cost of the coating is justified for an extension of sharpness life, for rust proofing and for less frequent cleaning.

That is not to say that I think those who prefer the uncoated rasps are wrong - they just have a different opinion to me, but I won't be purchasing uncoated rasps in preference to coated rasps. For me the difference is quite clearly in favour of coating.

PLEASE NOTE: The resolution of the pics is limited by websites, and the original larger images are much easier to draw conclusions from.

Cheers

FF

August 2013

- A claimed "sharp" life of up to 4 times longer than uncoated (it'll be some time before this can be determined

-

16th August 2013 05:55 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

16th August 2013, 06:37 PM #2

What is the difference in Cost?

TM

-

16th August 2013, 06:56 PM #3

I am sorry but until you put the results in a chart and post them on at least 4 forums I am unable to accept these results

-

16th August 2013, 07:03 PM #4

-

16th August 2013, 07:26 PM #5

Sorry Brett I'll go against you on this one. I have several coated and several uncoated, I have used them all extensivly and I have had zero clogging effects where I have had to stop and clean the rasp. I find that once the blue stuff has been roughed up a bit the clogging looks similar and I don't remember having one look that dirty coated or uncoated when I have stopped rasping (?) and I have used them non stop for hours on end sometimes. I still like the feel of the sharpness of my untreated and if I was to buy more (which I will) I will only buy untreated

Just had a look at mu untreated rasps under the big light magnifier and a 10x loup and after all the hours of work I have done on hardwood, various softwoods and a sh_-t load of Huon they don't show any signs of wear. I think you must have been rubbing that one on the steel vice

Just had a look at mu untreated rasps under the big light magnifier and a 10x loup and after all the hours of work I have done on hardwood, various softwoods and a sh_-t load of Huon they don't show any signs of wear. I think you must have been rubbing that one on the steel vice . UNLESS the quality of the rasps has dropped like the files

. UNLESS the quality of the rasps has dropped like the files I have a very little touch of corrossion but then I haven't looked after them as well as I could have. How long since I purchased them Brett?? 2years and 20,000 miles?

I have a very little touch of corrossion but then I haven't looked after them as well as I could have. How long since I purchased them Brett?? 2years and 20,000 miles?

Ban the Blue, stick to steel

-

16th August 2013, 07:48 PM #6

Yeah, it comes down to personal preference Mark. As I said I've been curious to see if there was any difference as far as I can tell. It was your comments, and also Ian's that got me wondering.

I think the difference in performance was only in the "feel" not in timber removed. That is a valid enough case for some people, such as yourself. There's a guy in France that prefers to use them without a handle simply because he gets a better feel for what's going on. And hey, a 40% price difference is certainly something to be considered when one needs quite a few rasps, as you do.

-

16th August 2013, 11:10 PM #7

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,793

Nice pics but the experimental design leaves a bit to be desired in that the testing simply does not address the original objective.

The clogging aspect is a bit of red herring and is not a away to assess sharpness anyway.

The experiment aim might be better achieved if

1) the rasps were cut and shaped so that the same amount of rasp area and profile is in contact with the wood.

2) The rasps are used with a constant applied force device for some maybe thousands of strokes

3) the weight of wood removed was graphed as a function of number of strokes.

The better rasps should maintain a more consistent rate of chip removal over time compared to those of poorer quality, but whether one could quantify anything out of this sort of experiment is another matter.

If the X4 was correct the area under the graph for the better raps should approach 4 x that of the poorer rasp.

However, since I do not believe it is possible to quantitatively define what is meant by a sharp "sharp working life" (for any tool) this means that any quantitative value assigned to a rasp being X time better is some what bogus.

-

17th August 2013, 12:09 AM #8

Ok, here is my 300mm Cabinet Makers #8 after something like a minimum of 30,000 strokes (at around 100/min), (probably more like 300,000). Under the magnifier it looks good, the camera does pick up a few little shiny tops but it still feels very sharp to your hand and on the wood. Sorry if my photos are not as good as FF's.

30 000 plus strokes.jpgOur lady of the Rasp.jpg

-

17th August 2013, 12:24 PM #9

It appears that you have not read what I said very carefully. I can't see how you could describe the clogging as a red herring when I went to some length to say that it hadn't impacted performance, and may have only been caused by the manufacturer applied oil (note that I pointed out that there appeared to be oil soaked dust). Furthermore, I point to this comment that I made:

"and may result in more regular cleaning being necessary for a given number of strokes" See the word "may"?

As far as the rasps not being identical I pointed out the differences and put several caveats on that. Should someone want to stump up the cost of two rasps of identical specs apart from the coating (around $300 from the webstore) then I'll be happy to repeat the experiment. Or perhaps it needs to be done by someone in a lab with all of the equipment that is available. Would you like to volunteer for the task?

As for applying constant force - as close as I could get. Being so pedantic about issues such as this is a little fruitless, because Joe Average in a workshop doesn't work like that. JA is going to base their assessment of a tool on how it feels to them, with their hands. I can't see how thousands of strokes are necessary when a mere thirty (plus uncounted strokes afterwards, but no more than another 20-30) has already revealed a wear pattern on the uncoated rasp. As I said, this is far more obvious in the flesh with a loupe.

Yes I thought about weighing the dust removal, but I figured that a fair person could see that the right hand rasp had removed a bit more timber (the dust pile is longer and thicker). As I also said there was a difference in the number of teeth in contact with the timber. All of those factors were against the coated rasp, and yet it had little to no signs of wear (remembering that it was not new, like the coated one was).

I am not stating an "up to 4x life" - this is the manufacturer's claim. I'm simply trying to find out if there is ANY evidence to support this claim, and the results make me think that there is. Others can draw their own conclusions. Claw Hama has different opinion to me and probably IanW does too. So what? This is my opinion and was quite clearly stated as such. Surely it is better to have at least some information, qualified and caveated as it has been, than none at all, isn't it Bob???

If I had laboratory equipment at my disposal the results would have been more empirical. At least I had the motivation to spend 4-5 hours conducting the tests, editing photos, uploading them and writing a short report full of qualifications and caveats.

Hey man, I'm just trying to put some information out there that may help someone decide if the rasp they are about to purchase NOW should be coated or not. My conclusion for my usage is that the coating is worthwhile. Someone who is about to purchase a rasp quite clearly doesn't want to wait for some years before a user can say that over a long period of time the coated rasp was or was not worth the extra purchase cost.

Similar Threads

-

A Dial Test Indicator Comparison

By Anorak Bob in forum METALWORK FORUMReplies: 41Last Post: 14th June 2013, 08:27 PM -

Old verses New

By GSRocket in forum METALWORK FORUMReplies: 17Last Post: 11th October 2012, 07:26 PM -

Chisel comparison test ideas?

By stuffy in forum HAND TOOLS - UNPOWEREDReplies: 8Last Post: 6th August 2011, 05:40 PM -

Video Comparison of Domino vs Dowelmax on Simple Joints

By HotChips in forum FESTOOL FORUMReplies: 11Last Post: 6th July 2008, 10:45 PM -

A Simple Stress Test

By Felder in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 43Last Post: 30th November 2006, 02:51 PM

Likes:

Likes:

Reply With Quote

Reply With Quote