Needs Pictures: 0

Needs Pictures: 0

Results 16 to 24 of 24

-

15th February 2018, 01:36 PM #16

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

-

15th February 2018 01:36 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

15th February 2018, 01:37 PM #17

funny you should say that Ian.

My dad always referred to his Record #078 as a fillister.

and on checking teh Record plane site just now I see that "officially" it's referred to as Record No. 078 Duplex Rabbet & Filletster Plane as illustrated in Catalogue No. 15, February 1938 http://www.record-planes.com/record-no-078-duplex-rabbet-filletster-plane/regards from Alberta, Canada

ian

-

15th February 2018, 04:13 PM #18

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

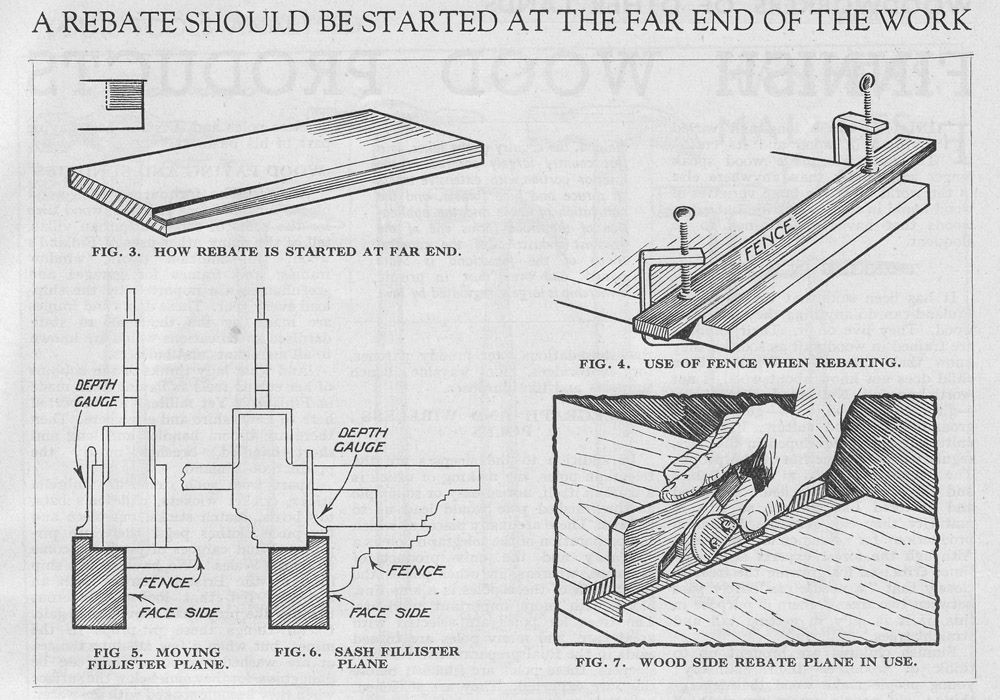

moving fillister plane was used for all rebates which were on the same side as the new edge of the work as in Fig. 5. In some jobs, however, the rebate had to be worked on the far side of the work, but still kept parallel with the near side - for instance, in making sash windows in which the wide glass rebate which occurs at the back of the wood must be made parallel with the front or face side. This brought into being the sash fillister plane which had a fence closing on to the side of the plane and which was held by long arms passing through the body of the plane. The difference between the two kinds of planes is shown clearly in Figs. 5 and 6, and it wiil be seen that, although the fence bears against the face side in both cases, the rebate is worked on opposite edges.An Introduction To Understanding Rebate Planes - Handplane Central

-

15th February 2018, 04:20 PM #19

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

-

15th February 2018, 05:25 PM #20

OK, seems like I had that a bit wrong; there are multiple definitions of 'fillister' which all have something to do with sash, either directly or indirectly. But "sash-fillister" seems like the safe bet if you want to define the rarer version of rebate plane, with nicker & depth-stop on the 'inside'.....

Cheers,IW

-

15th February 2018, 06:10 PM #21

Member

Member

- Join Date

- Oct 2005

- Location

- Mid North Coast NSW

- Posts

- 81

That's a good bit of advice this projection of the iron I mean. I thought it was my duff technique or the plane I'd bought on ebay was a dud that was producing slanted rebate walls. Having never owned or used on before. Until I happen to catch a post mentioning allowing the iron to project about the thickness of a business card . Voila! Perfect rebates!

Man can wait long time with open mouth for roast duck to fly in!!

Man can wait long time with open mouth for roast duck to fly in!!

-

16th February 2018, 12:42 AM #22

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2010

- Location

- US

- Posts

- 3,107

I have an identical plane to yours, but I had bought it NOS for a princely sum (about $200), as I'd had many others that were not new and just wanted something from griffiths. As you well know, it doesn't matter if they're NOS, they move over time, and mine needs some attention to the boxing being proud of the plane (but that's all).

They're wonderful planes to use, and cutting rebates in oak floor mouldings with a metal moving fillister was enough to convince me to sell that plane and keep a couple of these (this one and a hields, similarly constructed).

This is one where I think a lot of serious hand tool users screw up buying metal planes thinking that they need them for "accuracy" (instead of just marking their rebates, or cutting them slightly less critically perfect if they just need to house something that will be hidden).

(I wish I hadn't spent $200 on the one that I bought, there's no need for NOS and of the 8 of this type of plane that I've had, the repaired planes are easily as tight as the NOS planes - and I'm sure they'll keep moving over time, anyway. One would wonder why I had 8, but the reason is because I thought for a while that I might like to make half a dozen of these. I still might, but kept my two favorites. Making the hardware for them is a turn-off, and robbing hardware from a still-working plane is not something I'm willing to do)

-

27th February 2018, 12:30 AM #23

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

-

27th February 2018, 05:29 PM #24

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

Similar Threads

-

Moving Fillister Plane build.

By planemaker in forum HAND TOOLS - UNPOWEREDReplies: 43Last Post: 2nd March 2022, 10:46 AM -

Sharpening Skewed Blades for HNT Gordon Moving Fillister

By NewLou in forum SHARPENINGReplies: 11Last Post: 10th February 2017, 10:39 AM -

Skewed Fillister Plane?

By fudo133 in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 7Last Post: 19th August 2014, 10:54 PM -

Nooitgedagt Wooden Plane - Moving Fillister

By Ausworkshop in forum HAND TOOLS - UNPOWEREDReplies: 9Last Post: 11th October 2013, 09:27 PM -

Putting an old fillister plane to work.

By JDarvall in forum HAND TOOLS - UNPOWEREDReplies: 9Last Post: 11th November 2006, 10:08 PM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote