Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 9 of 9

-

6th May 2015, 01:05 PM #1

Member

Member

- Join Date

- Feb 2014

- Location

- Sydney

- Posts

- 70

What's the difference between bevel up and low angle (planes)?

What's the difference between bevel up and low angle (planes)?

Sorry if this has been asked (i couldn't find it or the answer on google)

What's the difference between bevel up and low angle? Is this just the same thing with different names?

I'm getting horribly confused Veritas have a BU smoother and a LA smoother - i can see they are different physical sizes, but are the terms just for marketing?

Veritas have a BU smoother and a LA smoother - i can see they are different physical sizes, but are the terms just for marketing?

Any help would be great!

Cheers, Dave

-

6th May 2015 01:05 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

6th May 2015, 02:15 PM #2

Well, the difference depends somewhat on who is using the terms and in what context.

Bevel Up (BU) planes are simply any plane that normally has the blade installed with the sharpening bevel uppermost, i.e., the bevel forms the 'cutting angle'. I say 'normally' because with some planes (the products of HNT Gordon being the best-known!), you can reverse the blade to give an extremely high cutting angle that effectively turns your plane into a scraper, but these are not generally referred to as BU planes because they aren't intended for primary use with the blade BU.

I haven't any way to make a diagram where I'm typing this, but bear with me & I'll try to make myself as clear as I can:

On dedicated BU plane, the bed, or frog angle is generally somwhere between around 22.5 degrees, to as little as 12.5 degrees ( which are about the practical limits for a few reasons). On these planes, the cutting angle is not the bed angle, it is instead formed by the sharpening bevel of the blade because that's what actually meets the wood, plus the bed angle. The combination of these usually gives you a cutting angle somewhere south of about 50 degrees, but it is highly variable because BU lanes come with different bed angles & sharpening bevels are user-selected. Which finally gets me to my point: If you use the term 'low-angle' and you are talking strictly about BU planes, you are generally meaning a plane with a bed angle around the 12.5 degree area, as opposed to the higher 20 or so degrees of many BU block planes, for e.g. Low-angle BU planes, in stock trim, have a lower cutting angle than most Bailey type bench planes, but not by much (12.5 +30 = 42.5; less if you sharpen to a more acute angle). So 'Low-angle' can refer to both the bed angle (which is what it usually implies) or the actual cutting angle, in this context. A 20 degree bed will give you a cutting angle higher than those of your typical bench planes (20 +30 = 50 known as "York pitch" on a bench plane).

On bog-standard Bailey type planes, where the bevel goes down, and provided you are using the regular style of flat or parallel blade (as opposed to tapered blades which were common in old wooden planes), the top of the blade forms the cutting angle, & since the top of the blade is parallel to the bed (frog) it follows that the cutting angle will be the same as the bed angle, i.e. 45 degrees. If you want to increase the cutting angle on one of these planes, you can do so by honing a small 'back bevel', i.e. a bevel on the side opposite what you would normally do. Because the blade is otherwise symmetrical, you could even turn it over and then you would have your sharpening bevel (usually in the ballpark of 25-30 deg) added to the bed angle, giving you a cutting angle of 70-75 degrees; almost a scraper. However, you might get into trouble doing that, because you will have to set the cap-iron/chipbreaker back to clear the bevel, which means you may not be able to extend the cutting edge far enough out to cut (on some planes you can), and you might also get chatter problems, depending what you are trying to do with it.

Now, the pros & cons of different cutting angles and their applications to different circumstances are the subjects of many threads and their contents run to many pages. It's also a mildly to moderately contentious subject, so I'm not about to go there. I think I have probably confused you enough for one day..........

Cheers,IW

-

6th May 2015, 03:34 PM #3

Or to simplify Ians answer from six paragraphs to one

... All low angle planes are bevel-up, but not all bevel-up planes are low angle. In the case of Veritas planes, they interchange the terms bevel-up and low-angle freely. For example, the Bevel Up Smoother; Low Angle Jack and Bevel Up Jointer all have the same bed angle and interchangeable irons - but different names. Go figure.

... All low angle planes are bevel-up, but not all bevel-up planes are low angle. In the case of Veritas planes, they interchange the terms bevel-up and low-angle freely. For example, the Bevel Up Smoother; Low Angle Jack and Bevel Up Jointer all have the same bed angle and interchangeable irons - but different names. Go figure.

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

6th May 2015, 04:10 PM #4

Member

Member

- Join Date

- Feb 2014

- Location

- Sydney

- Posts

- 70

Thanks Guys!!

It all makes sense. Awesome explanations!

-

6th May 2015, 05:19 PM #5

-

6th May 2015, 07:54 PM #6

well aged but not old

well aged but not old

- Join Date

- Sep 2004

- Location

- Brisbane

- Posts

- 925

I have no idea. I have no 4 BU smoothing plane and a low angle block plane and they are just names to me.

My age is still less than my number of posts

-

6th May 2015, 11:52 PM #7

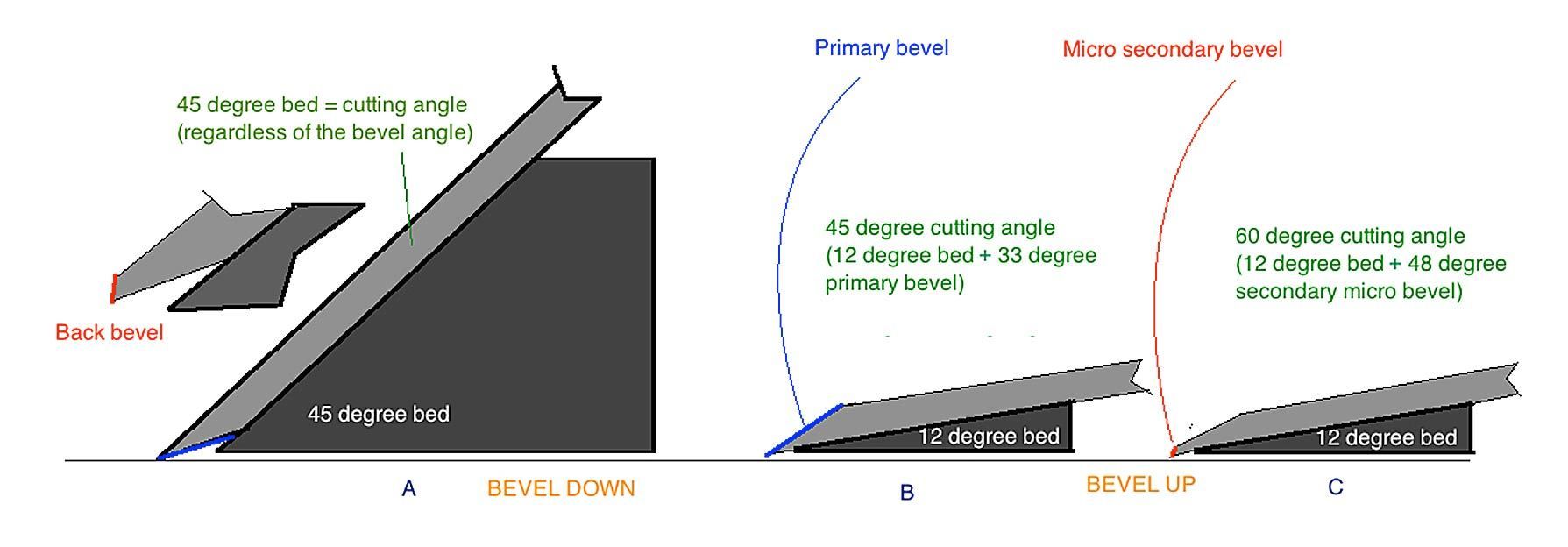

A picture is worth a 1000 words.

- The bevel faces down in BD mode. The cutting angle is obtained from the angle of the bed.

- To alter the cutting angle in BD, a back bevel (BB) is added to the blade. The result is additive: Bed angle + BB = cutting angle (e.g. 45 degree bed+15 degree back bevel = 60 degree cutting angle)

- The bevel faces up in BU mode. The cutting angle is obtained from the angle of the bed + the bevel angle.

- To alter the cutting angle in BU, a secondary bevel is added to the existing bevel. The result is also additive: Bed angle+Secondary bevel angle (e.g. 12 degree bed+50 degree secondary = 62 degree cutting angle).

Regards from Perth

Derek

Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

7th May 2015, 09:27 AM #8

Thankyou, Derek - that's just the illustration I needed. It certainly reduces the need for words.......

Cheers,IW

-

7th May 2015, 09:46 AM #9

Member

Member

- Join Date

- Feb 2014

- Location

- Sydney

- Posts

- 70

That's great,

Thanks again!

Similar Threads

-

Bevel down, bedding angle and primary bevel

By monoman in forum HAND TOOLS - UNPOWEREDReplies: 28Last Post: 8th July 2009, 02:10 AM -

Having trouble understanding low-angle vs high angle planes

By wsal in forum HAND TOOLS - UNPOWEREDReplies: 4Last Post: 2nd December 2008, 12:04 AM -

Bevel angle testers

By rsser in forum WOODTURNING - GENERALReplies: 7Last Post: 21st October 2008, 01:45 AM -

New/old bevel ripping guide - difference?

By princhester in forum TRITON / GMCReplies: 7Last Post: 31st August 2005, 12:00 AM -

Bevel Up Planes With Back Bevel

By Termite in forum HAND TOOLS - UNPOWEREDReplies: 21Last Post: 17th August 2005, 08:46 AM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote