Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 20

Thread: European table saw fences

-

17th September 2009, 02:53 PM #1

New Member

New Member

- Join Date

- Nov 2008

- Location

- CNY

- Posts

- 2

European table saw fences

European table saw fences

A few weeks ago I read an article about European table saws. The author said that most European table saw fences end just past the blade because the fence served no purpose once the wood cleared the blade.

I didnít give it much thought but today I was doing some ripping and as the stress was relived the boards were warping towards the fences and binding. It appeared that short fences would elevate the binding.

Any pros or cons on the short fence?

-

17th September 2009 02:53 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

17th September 2009, 03:45 PM #2

Don't know. But I would think that if you were passing stock of a long length through and it was only supported by a fence that ended just past the blade that the stock would have the tendency to wander because that not yet cut had little support past the blade against which it is being pushed against.

-

17th September 2009, 09:24 PM #3

Awaiting Email Confirmation

Awaiting Email Confirmation

- Join Date

- Sep 2007

- Location

- Northern Brisbania...

- Posts

- 791

Dear Gary,

I totally agree with Waldo. The Euro's place too much faith in the stiffness of their Riving Knives. It wouldn't take too much twisting of the timber at all (due to a lack of Fence-length) to get the rear-edge of the Blade to leave rings on your stock. Within days of purchasing it, I ripped the 600mm job off my Site-Saw and replaced it with a full 1.2m length of aluminium channel, which thus hangs 200mm off both the front and the rear edges of the table (just for good measure... )

)

Here's a fota' for ya' (the scrawny piece of ally in front of the Channel is the original excuse-for-a-fence... )

)

Attachment 116731

Best Wishes,

Batpig.

-

17th September 2009, 10:39 PM #4

Batpig, you put them in the shot for a reason, so who are the photos of the two blokes?

-

18th September 2009, 07:09 AM #5

Awaiting Email Confirmation

Awaiting Email Confirmation

- Join Date

- Sep 2007

- Location

- Northern Brisbania...

- Posts

- 791

Dear Waldo,

Given that I am "recycling" the photo after originally using it in another thread well over a year ago, and given that nobody picked 'em back then, I therefore have to say - very well done Old Chap... (you should become some sort of an FBI "Profiler" - looking for all those little seemingly insignificant clues...

(you should become some sort of an FBI "Profiler" - looking for all those little seemingly insignificant clues... )

)

One of them is my Dear Old Dad, and the other is a picture of an Italian Saint (my favourite) that everyone used to think was a photo of my Dear Old Dad. The photos were at hand in the room there at the time, so into the shot they went...

Best Wishes,

Batpig.

-

18th September 2009, 11:02 AM #6

It's always interesting to look behind the subject of shots to see what people have in and around the shed. It's a bit like watching a movie and looking past what they want to watch to see what you might not have other wise noticed.

It's always interesting to look behind the subject of shots to see what people have in and around the shed. It's a bit like watching a movie and looking past what they want to watch to see what you might not have other wise noticed.

-

18th September 2009, 02:35 PM #7

New Member

New Member

- Join Date

- Nov 2008

- Location

- CNY

- Posts

- 2

Thank you, for in put. I donít think I will try it.

-

18th September 2009, 10:37 PM #8

Awaiting Email Confirmation

Awaiting Email Confirmation

- Join Date

- May 2007

- Location

- Gold Coast

- Posts

- 281

The bed and pillows in the back ground of Batpigs saw also offers plenty of contrast.

-

19th September 2009, 02:42 AM #9

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

Half fences work and that is what the Euro fences are. As an experiment attach a subfence to your main fence that only goes to about mid blade behind the leading edge of the blade and try it. It is actually far safer than a full length fence and just as accurate hard as that is to believe.

CHRIS

-

19th September 2009, 04:44 AM #10

Deceased

Deceased

- Join Date

- Jan 2006

- Location

- poland

- Age

- 78

- Posts

- 761

Not all the Euro saws comes with "Short Fence"...

to clarify:

*The "Short fence" is NOT "Short", it's a full length fence that can be pulled back and by that, even be used as a locator for cross-cutting same length pieces.

*The "short Fence is used ONLY TO RIP SOLID WOOD...for man made boards like MDF, Plywood or Chipboard you MUST use the FULL LENGTH of the fence.

I wasn't sure about the position of the short fence so, I've sent an e-mail to Metabo and got this reply...

---------------------------------------------------------------

Dear customer,

thank you for your email regarding the setting possibilities of the rip fence.

Reactive woods (not dead woods) can move to the side just after cutting. Thatīs why there might be the risk of a kick back if the rip fence is set in the long position.

In order to minimize this it is recommended to set the end of the rip fence to the saw blade centre (short position).

For sawing dead wood like chipboards it is recomended to set the rip fence in the long position in order to achieve the maximum guiding length.

The riving knife is absolutely necessary and the correct position of the rip fence has to be chosen according to the wood!

If you have further questions please feel free to contact me.

Furthermore enjoy woodworking!

With best regards

-------------------------------------------

Florian Fischer

Produktmanager Holzbearbeitung

Product Manager Woodworking

Phone: +49 (0) 70 22-72-2529

Fax: +49 (0) 70 22-72-2074

Email: [email protected]

metabo

work. don't play.

----------------------------------------------------------------------------------------------

Most of the Americans are very sceptic as for the short fence so I made for them especially "In front of the camera pictures"....

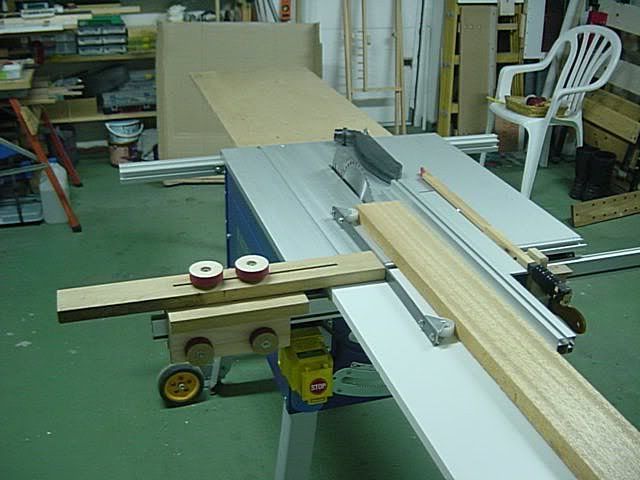

This is my setting. As you can see, I'm using the "Rollers Feather board" (I never rip a long board without them).

Also, please note that I'm using Infeed and Outfeed table that are, IMO, are very important.

I don't use the "rollers Outfeed table" first, because I don't have it and second (and maybe more important), I read somewhere that the rollers might pull or push the board to one side leading to a dangerous situation (if they are not exactly lined up with the TS).

Closer view, please note how much of fence support I have before the blade - 24" - that is holding the board attached to the fence far before it enters the blade.

You can see the simple - but very long - push stick...28" long so even when I push the board past the blade, my hand is still very far behind.

I set the fence almost to the Arbor center (the hole that you see on the table near the blade center is for pushing a pin to lock the Arbor for blade change).

As you noticed, I love "high blade" for ripping solid wood. It's easier on the motor, the feed rate is faster and the cut is cleaner without burn marks but of course, I use the blade guard that covers this "meat and bones slicer" totally.

Ready to cut...please note that I'm using the "Low fence even though the board is 1ľ" thick.

It gives me more "open area" and actually the "High fence" in not needed even if the board was 3" except in the case of re-sawing (that I never did on the TS)

I'm still using my hand to push the board from the end

But that's the point that I revert to push stick

Last push.....

Done...please not where is my hand when the cut is finished...

As you can see, no burn marks even though I use 60 tooth blade.

I took another board....longer - 75" that, if you call it "not straight", it's a "compliment" for this board...

Same procedure...

Finished...

Regards

niki

-

19th September 2009, 08:51 AM #11

Awaiting Email Confirmation

Awaiting Email Confirmation

- Join Date

- Sep 2007

- Location

- Northern Brisbania...

- Posts

- 791

Greetings Jigmeister-Niki,

Great post as usual... Your photos illustrate very well what must be the thinking behind their typical Fence setup, in so far as they figure that the stock will be guided through those critical last few inches by a "tunnel" formed from the Knife on one side and the end of the Fence on the other. As a matter of fact, the reply from Metabo to your e-mail suggests that with their short Fence arrangement, they are deliberately attempting to avoid the risks of sudden "bowing" of the stock due to residual stresses that might only be revealed when the offcut has come off...

Your photos illustrate very well what must be the thinking behind their typical Fence setup, in so far as they figure that the stock will be guided through those critical last few inches by a "tunnel" formed from the Knife on one side and the end of the Fence on the other. As a matter of fact, the reply from Metabo to your e-mail suggests that with their short Fence arrangement, they are deliberately attempting to avoid the risks of sudden "bowing" of the stock due to residual stresses that might only be revealed when the offcut has come off...

But in the back of my mind, I can't help thinking that even if the Knife was absolutely rock-solid and didn't budge at all, the stock could still rotate into the Blade's teeth (front or rear) if it started to "wander" on the outfeed side of the blade, due to slight non-flatness in either the Table surface, or the underside face of the Stock. Mind you, those Krafty Krauts probably think that everyone has their own Planer/Thicknesser . But having said that, if you get the time between knocking up some Jigs, can you please comment on the following:

. But having said that, if you get the time between knocking up some Jigs, can you please comment on the following:

1) Just how rigid is your Riving Knife?

2) What is its thickness, and does Metabo give a specific "Achtung!" regarding Blade kerf?

Best Wishes,

Batpig.

-

19th September 2009, 07:47 PM #12

Deceased

Deceased

- Join Date

- Jan 2006

- Location

- poland

- Age

- 78

- Posts

- 761

G'day mate

First, to your questions...

1) I cannot tell how rigid my riving knife is but I made a photo and as you can see, the riving knife pivot is at the same level like the arbor...generally speaking it's quite rigid...

Please note that Metabo did not talk about "Preventing" the kickback but "Minimizing the risk of kickback"...I don't have personal experience but, I read that the kickback risk is still there even with the riving knife and the short fence - but with much, much less chances than without them.

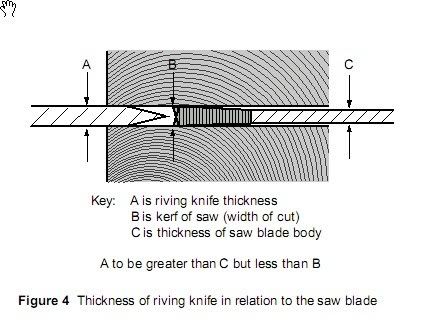

2) My riving thickness is 2.3mm but you have to take into consideration that Metabo is supplying the saw with Metabo blade ("thin kerf" ---Blade Body - 2.0mm --- Kerf -2.4)...the riving knife thickness should be as on the drawing below and you must consider it if you are using other blades (i.e. "full kerf" blade).

The short fence is not mandatory but a suggestion to minimize the kickback risk in case of "Reaction Wood" that springs out (toward the rip fence) after being severed

The riving knife will minimize the kickback risk in case of an "Operator error" or from a case the wood "Springs in" as on the pictures below...

I already "advertised" the short fence here...my only mistake was to set the fence 1"~2" beyond the front teeth that was according to some suggestions while the correct position is the center of the blade...

https://www.woodworkforums.com/f44/table-alignment-short-fence-76604

As for the short fence, it's also recommended by Jim Tolpin (Table Saw Magic)...

http://books.google.com/books?id=BYW...0fence&f=false

And, Ian Kirby (The Accurate Table Saw)

http://www.woodworkersjournal.com/Ma...cles/3942.aspx

A nice video by Steve Maskery

[ame="http://www.youtube.com/watch?v=d7QXIN2X8-w"]YouTube - Safer ripping with a short rip fence on the tablesaw[/ame]

More about safe operation of the table saw (recommended to read)...

http://www.hse.gov.uk/pubns/wis16.pdf

Best regards

niki

-

19th September 2009, 09:27 PM #13

Awaiting Email Confirmation

Awaiting Email Confirmation

- Join Date

- Sep 2007

- Location

- Northern Brisbania...

- Posts

- 791

Dear Niki,

Yet another enjoyable post! You must just about have the camera permanently mounted on a tripod in the workshop by now...

But yes, I can see what you mean about the Short-Fence giving the Stock enough "breathing space" to not end up riding up on the rear-teeth of the blade in a big "kickback"... It appears that if you've got a nice flat Table and you're working with nice flat Stock, you'll probably be better off (at least from the Safety point-of-view) with the "Shorty". But with the sheet-metal top on my current "ride" (a 315mm "Site Saw" as you can see from my photo... I'm still keeping my eyes "peeled"

It appears that if you've got a nice flat Table and you're working with nice flat Stock, you'll probably be better off (at least from the Safety point-of-view) with the "Shorty". But with the sheet-metal top on my current "ride" (a 315mm "Site Saw" as you can see from my photo... I'm still keeping my eyes "peeled"  ), I'll be sticking with my 1.2m job, with the Safety coming from my prodigious pulling of the Stock against the Fence at all times before, during, and when exiting the cut...

), I'll be sticking with my 1.2m job, with the Safety coming from my prodigious pulling of the Stock against the Fence at all times before, during, and when exiting the cut...

That setup you cite where your Knife is slightly thinner than your Kerf, but thicker than your Body, is by all accounts the recommended one (and is indeed the prevailing setup on my Saw), but since with your Short-Fence you're not pulling your Stock against a Fence (and thus away from the Blade) at the end of the cut, have you therefore ever found "teeth-arcs" from the trailing edge of the Blade on either your Stock or your Offcuts?

Best Wishes,

Batpig.

-

19th September 2009, 11:48 PM #14

Deceased

Deceased

- Join Date

- Jan 2006

- Location

- poland

- Age

- 78

- Posts

- 761

Hi mate

No, I don't get any "Teeth-arcs" (or as they are usually called "tooth marks").

IMO, you get tooth marks, if the blade is not parallel to the miter slot or, the rip fence is not parallel to the miter slot or, the workpiece is not straight and "pulls" to one side or another or, when the blade is set low...as you could see, I love the "High blade" that gives me very smooth cut and lets me to use a 60, 80 or even 100 tooth blade for ripping 30mm thick white Oak and getting "finished" cut (just a little bit of sanding)...the best is if you try it yourself.

I would like to emphasize that in a perfect world where the wood is dried properly, no odd grain direction changes and doesn't have any internal stresses, no kickback will happen even without the riving knife and/or short fence...a little bit of "twisting" is also "forgiven"...it's a fact that I was working for 10 years on the table saw below and never got a kickback...

Attachment 116889

The riving knife and the short fence will protect us from a few cases that the kickback can occur...

Your method of keeping the wood against the fence is very good and will help to prevent the (what I call) "Operator error" kickback but, in the very few cases that the wood is "Reactive" and springs toward the fence, even the riving knife might not help you...

Long time ago (before I was "converted" to the short fence) I made a shop-made long fence (in Europe, we don't have "after market" fences) that I was using with the "Hold down rollers" that keeps the boards pressed to the fence (kind of Board Buddies)...

On the pics below, please note the big push shoe that I used to push and hold down the board so even if the saw wanted to kickback, I was holding the board down with almost my all body weight...I could hear the saw noise changing but I hold it down and did not let it go...

I started to use the short fence some 3 years ago but I will admit that it took me some time to get confident (what? no support beyond the blade???!!!) but after a few times I got confidence and nowadays, I don't have any "psychological" problems with it but...if you feel safer using your method - do it your way...

Regards

niki

-

20th September 2009, 07:06 AM #15

Awaiting Email Confirmation

Awaiting Email Confirmation

- Join Date

- Sep 2007

- Location

- Northern Brisbania...

- Posts

- 791

Dear Niki,

Thanks again. If I ever get around to doing some planned "stiffening" mods to my Saw's Table, I'll throw the "Shorty" back on to the Fence Clamp and at least give it a try. In the meantime, I'll keep my eyes peeled for some "reactive" timber...

(Might be easier to find if I go out to the shed looking for some at night, with all of the lights turned off... )

)

Best Wishes,

Batpig.

Similar Threads

-

High Fences with Triton Router Table

By counstefan in forum TRITON / GMCReplies: 19Last Post: 5th March 2004, 11:21 PM -

Triton Router Table Fences

By Sturdee in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 11Last Post: 18th February 2004, 02:56 PM -

router table fences

By dereg in forum ROUTING FORUMReplies: 0Last Post: 20th October 2003, 01:15 PM -

router table fences

By dereg in forum WOODWORK - GENERALReplies: 0Last Post: 20th October 2003, 01:08 PM

Reply With Quote

Reply With Quote