Thanks: 0

Thanks: 0

Results 16 to 22 of 22

-

16th August 2018, 07:22 PM #16

Taking a break

Taking a break

- Join Date

- Aug 2008

- Location

- Melbourne

- Age

- 34

- Posts

- 6,127

I'm noticing that where I am working now. You look at the German machines and everything is well built and all the working surfaces are finely ground, then you look at the Swiss version of the same machine and it's just nicer; the castings are works of art (they're not even ornate, but you can see that a lot of work went in to making every part line up exactly with its neighbour), the knobs and levers feel nicer, the dials all have a satin chromed finish and every surface is hand scraped. Swiss is definitely 11

-

16th August 2018 07:22 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

17th August 2018, 07:51 PM #17

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,785

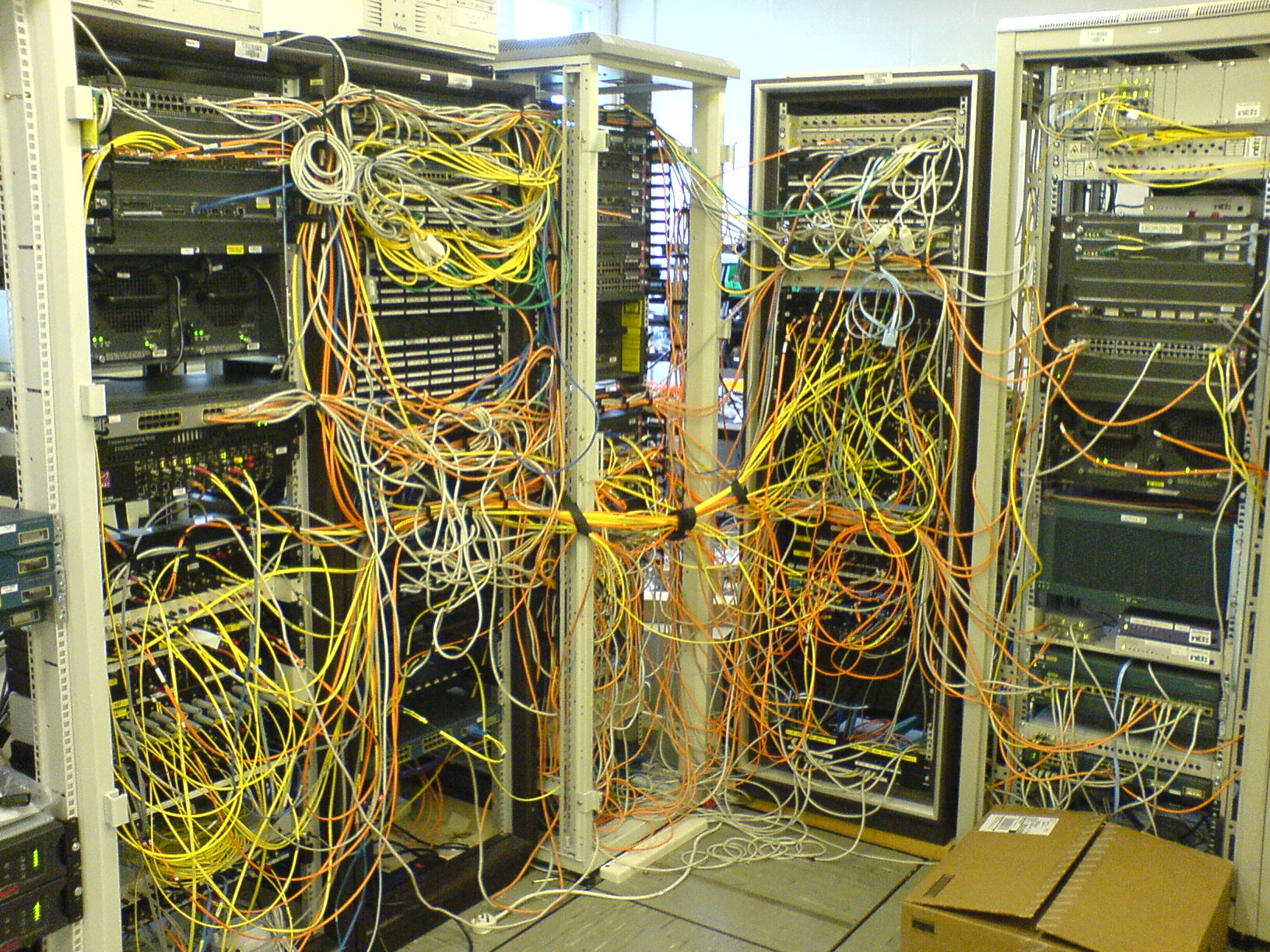

My cousin who is an electrical engineer sent me this

-

17th August 2018, 10:34 PM #18

Back in the 1970's I did some summer work as a tech assistant wiring a new crossbar telephone exchange in Clayton. Stacks of 100 pair cables came in from the streets and fed down through tall MDF frames for termination. The cables were all laced together into tidy blocks using waxed string and a flat hooked lacing needle. Time consuming but it looked nice and the pairs were terminated by stripping, wrapped and soldered. I noticed at the time that the newer the cable blocks became throughout the exchange the less skilled and or diligent was the lacing... I suppose these days they just randomly bundle stuff together with cable ties and punch down the unstripped ends. I don't remember anybody using a tone generator to trace cables then, so I guess they had to have a better physical way of tracing cables visually. The OCD in me still likes nice neat orderly cable runs.

Franklin

-

18th August 2018, 07:40 AM #19

Unfortunately that mindset also occurs on telecommunications radio & mobiles sites using waveguides from the antennas to the equipment. We have seen quite a few examples from contractors building mobiles sites. Looks very neat and pretty but not good from a performance aspect. When you see neat and pretty it usually means a lot of non-compliance notices will issue on the external build. Radio waves don't go around 90 degree bends so well, but will follow nice gentle loopy curves. There is beauty and pride of workmanship evident in well formed waveguide bends and engineered waveguide "plumbing."

I was never a telco tech, just a humble surveyor in the background, but got to see some of the marvels of radio technology when we built the microwave bearer systems in the 1970's onwards. Some of the transitions from waveguides to the equipment were marvels of engineering and manufacturing technology using materials and production methods of the highest quality. Sadly most of it went into scrap metal skips in the 2000's.

I wonder if these nice tight bends in HV wiring are creating localized hot spots where cable conductors have potentially been damaged in the forming / bending process???? Mobyturns

Mobyturns

In An Instant Your Life CanChange Forever

-

19th August 2018, 12:00 PM #20

Taking a break

Taking a break

- Join Date

- Aug 2008

- Location

- Melbourne

- Age

- 34

- Posts

- 6,127

Meanwhile....

-

9th September 2018, 01:03 AM #21

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2015

- Location

- Ringwood, VIC

- Posts

- 575

You can still see the patch panels...

I've worked in rooms like this..

https://goo.gl/images/LW7izY

Sent from my SM-G965F using Tapatalk

-

9th September 2018, 09:02 AM #22

The exchange MDF's were a work of art - https://www.google.com.au/search?q=m...aSHzu4S2FldIM:

Mobyturns

In An Instant Your Life CanChange Forever

Similar Threads

-

Plastic "Bung Taps" - I want to "click" a garden hose onto the end of one...?

By Batpig in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 4Last Post: 7th May 2017, 04:05 PM -

Why do so many "private" eBay sellers only offer "local pickup"?...

By Batpig in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 27Last Post: 16th July 2016, 08:57 PM -

What does "supa砥石" and "njuseramikusu" mean on a whetstone?

By Russell Cook in forum SHARPENINGReplies: 12Last Post: 26th December 2012, 02:51 PM -

eBay: How long can you "Save" the "Draft"-listing of an item you want to sell?...

By Batpig in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 0Last Post: 22nd January 2011, 06:04 PM -

"I see stupid people!" or "spot the blithering idiot"

By journeyman Mick in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 46Last Post: 29th October 2010, 07:29 AM

Likes:

Likes:  Needs Pictures:

Needs Pictures:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote