Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 28

Thread: Troubleshooting the Transmig 195

-

24th August 2011, 09:54 PM #1

Tool addict

Tool addict

- Join Date

- May 2008

- Location

- Perth

- Posts

- 164

Troubleshooting the Transmig 195

Troubleshooting the Transmig 195

Hi guys,

I was able to finally fire up my $62 Transmig rural pack last night. And something is not quite right

The wire heats up, forms a bit of a blob, feeds into that blob, and that's about it.

There isn't an arc, the base metal doesn't heat up. The best description is that it looks like a large piece of slag. Reading the old manual that I have a PDF of, the fault I'd link it to is "Cold weld puddle", suggesting that the rectifier faulty, but Googling isn't giving me any help or confirmation.

Now, I know how to test a rectifier, but I don't know how to identify it in this machine.

I'll be an extremely happy man if anyone can help me with: what this particular problem is; how to spot the rectifier in this welder; supplying a wiring diagram for the old girl.

I don't want to rush off a welder repairer just yet, because the more I can learn about this beastie the better

Cheers

-

24th August 2011 09:54 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

25th August 2011, 12:34 AM #2

Member

Member

- Join Date

- May 2008

- Location

- Sydney

- Posts

- 77

Hi Lordbug,

I am Pete from Tokentools welding

The rectifier will be a stud diode mounted within the heatsink. Look for a device that is sitting in the middle of the heatsink with a connection on it running off to the wire feeder. Unplug it and connect a multimeter on diode test and check flow in both directions. It should give between 0.4 and 0.7 volt drop in oe direction and open circuit in the other.

Also, if you short circuit the output terminals and meter this via a DC current clamp (tong tester) you should be able to get a reading of actual current and deduce if it is stuffed.

regards

Pete (excuse typos.....had a few beers )

)

-

26th August 2011, 12:00 PM #3

Tool addict

Tool addict

- Join Date

- May 2008

- Location

- Perth

- Posts

- 164

Hi Pete,

I've read plenty about you, plenty of good stuff, so as corny as it sounds I feel as though I'm being addressed by fame

Now, I've had a look at what a stud diode looks like, and I'm not having any luck in spotting anything that looks like them. So here's some photos of the innards of the old girl

The wire feeder is a remote unit, and looking at the photos, there isn't a particularly good one showing the cable that heads out to it.

I know it'll be the most obvious part, but better to have it pointed out instead of thinking it's something else

Cheers!

Bertil

-

26th August 2011, 01:47 PM #4

I'd say it's those things in the aluminium sheets.

EDIT: looking closer, they may be SCR's ... it's just a little hard to tell from the photo's. Still chances are they are what you are looking for.Cheers.

Vernon.

__________________________________________________

Bite off more than you can chew and then chew like crazy.

-

26th August 2011, 04:36 PM #5

Member

Member

- Join Date

- May 2008

- Location

- Sydney

- Posts

- 77

Hi,

I am flattered , Autographs are free, kisses are $1

, Autographs are free, kisses are $1

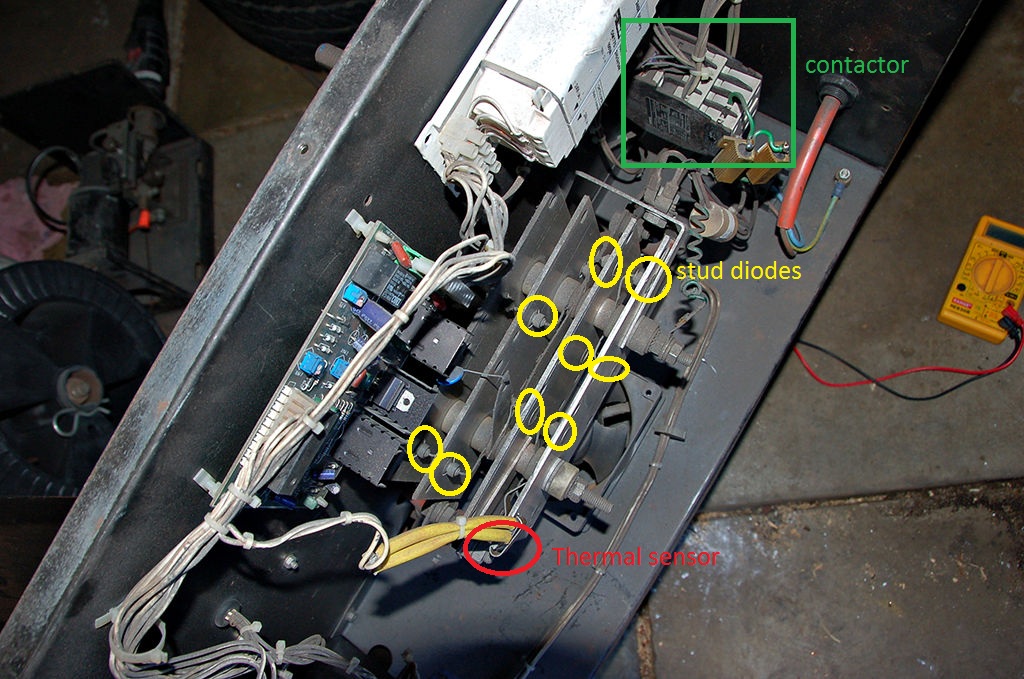

I have attached a pic showing the diodes circled in yellow. I think there are more than I can see so check them all. Also there is a thermal sensor that you need to check, they are normally closed circuit for correct operation and open when too hot.

I believe the contactor at the rear should close when you press the trigger and this in turn connects the 240V to the main transformer as well as motor feed circuit and gas solenoid.

It is a good machine with filtering capacitors on the output.

If you are unsure then it would be best to get a sparky to have a look at it.

-

5th September 2011, 02:23 PM #6

New Member

New Member

- Join Date

- Sep 2011

- Location

- Mackay, Qld, Australia

- Posts

- 3

Diode problem

Diode problem

I had a large battery charger that had faulty diodes that tested ok with a multimeter but then failed\'broke down' under load. An oscilloscope allowed me to see the breakdown. I just had to replace all of the diodes to fix the problem.

-

8th September 2011, 12:46 AM #7

Intermediate Member

Intermediate Member

- Join Date

- Jan 2010

- Location

- Allansford

- Posts

- 26

I bought a secondhand Transmig 195 about 15 years ago. It looked fairly new. The seller was selling it because her husband had died. My nephew had one the same and it welded beautifully. I bought this welder without trying it. I too was very disappointed when I got it home

. It would not weld either. I consulted nephew (he bought his brand new). He said his capacitors failed at one stage and they were replaced under warranty. I then bought 3 new capacitors ( I forget but I think I bought some that were about double the capacity of the originals on advice of said nephew) (I just read the details off the capacitors and selected my own without the help of a welder shop or similar) I think the price at the time was $150 to $200. When I put them in the machine was as good as new. It is still going. I am only a hobby welder though. This may help.

. It would not weld either. I consulted nephew (he bought his brand new). He said his capacitors failed at one stage and they were replaced under warranty. I then bought 3 new capacitors ( I forget but I think I bought some that were about double the capacity of the originals on advice of said nephew) (I just read the details off the capacitors and selected my own without the help of a welder shop or similar) I think the price at the time was $150 to $200. When I put them in the machine was as good as new. It is still going. I am only a hobby welder though. This may help.

Ken

-

8th September 2011, 07:22 PM #8

Member

Member

- Join Date

- Sep 2011

- Location

- Sydney

- Posts

- 55

It could be a gun problem sometimes the power cable can come out of the block in the handle or at the power source if this happens the current is transferred to the work piece via the welding wire which glows red and just melts onto the metal its a surprisingly common fault

-

13th September 2011, 01:28 PM #9

Tool addict

Tool addict

- Join Date

- May 2008

- Location

- Perth

- Posts

- 164

Haha, I get a feeling you may be the winner dubman, and if that's the case, I'm going to wish I'd held off a week before taking the machine in for a checkup

Took it to a local place, heard back today. The fellow said that it was running perfectly fine, the voltages being put out were what was expected.

So very simply, the problem was either fixed in transport (loose wire, arrg), or there's a problem with the power supply in the shed. I'll take it home and have a test, and possibly a fiddle of some wires if it does it again. If it doesn't go away, I'll get a sparky in. If it does go away, I'll just have to laugh, too many times have I experienced the "Take it for a drive" method of fixing something

On the plus side, I was informed that the fan is on the way out, it's meant to start as soon as power is supplied, but currently it takes five to ten minutes before it starts up. I've opted to replace that myself, to get closer acquainted with this beautiful beast.

Can't wait to pick it up later on today!

-

13th September 2011, 09:09 PM #10

Tool addict

Tool addict

- Join Date

- May 2008

- Location

- Perth

- Posts

- 164

All is still not well in my humble abode

The problem is persisting. Admittedly, it's running a little better, but barely usable.

I'm taking a brief break to cool my head and prepare myself before I start checking all the connections are fine.

I just want to check though. Would the voltage being supplied to the machine have any particular affect on the workings?

Currently, I'm measuring 255 volts AC at the terminal just inside the machine.

You can't quite make out the text, but in photo #3, the white transformer up the top left is meant to put out 24v on the two sections. Measuring there, it's currently supplying 26.5v.

I'll have to give the place I took it to a call tomorrow, to see if they don't happen to have any ideas or know what their mains voltage is at, because apparently the machine was working beautifully.

-

14th September 2011, 06:57 PM #11

Member

Member

- Join Date

- Sep 2011

- Location

- Sydney

- Posts

- 55

The input voltage @250v is ok so is the 26v at the transformer

As it happens I have one of these machines in my work shop so at the weekend I will post the various voltages

One thing you can try now to rule out a gun problem

measure the o/c voltage between the out put terminals at the power source

then switch one probe to the contact tip, the voltage should be the same if not check the power cable in the gun (I would still take the handle apart and have a look at the connection )

next move the other probe to the earth clamp the voltage should be the same

if not check the earth lead

If the machine works for a while then starts loosing power look for the hot connection (the lug at the wire feed maybe )

The repair shop might not have load tested the machine

Finally or that should be firstly make sure you have the correct size contact tip

strange things can happen if its too big -)

-

16th September 2011, 10:54 PM #12

GOLD MEMBER

GOLD MEMBER

- Join Date

- Sep 2010

- Location

- Lebrina

- Posts

- 1,099

I am still leaning towards a faulty diode.

A machine with a faulty diode can and will still put out what appears to be a correct voltage figure but not weld, as you are experiencing. This is due to the fact that in effect the welder is supplying a pulsed current to the wire rather than a constant current. Most multimeters will not show this, although I suspect that one that records frequency may.

I have experienced this exact same condition on several welders and it has always been a diode.

I would not suspect faulty capacitors as the primary cause, these merely smooth the arc.

I may add that welder repair seems to be a field that many electricians cannot fathom.

-

17th September 2011, 10:18 AM #13

New Member

New Member

- Join Date

- Sep 2011

- Location

- Mackay, Qld, Australia

- Posts

- 3

try putting your multimeter in ac mode and measure the output voltage etc at the tip. If you are getting a reading of say 20v ac then it is a diode. You may see up to 1 or 2 volts ac or less if diodes are ok.

capacitors completely not working or removed can also show a high ac voltage. Capacitors that are failing usually get boulged on the top.

this is not the end of the story however. Sometimes the diodes work correctly under no load, and fail when load is applied. Not sure how you would test this without an oscilloscope. Take it to an electronics repair guy, someone who repairs televisions.

-

17th September 2011, 08:31 PM #14

GOLD MEMBER

GOLD MEMBER

- Join Date

- Sep 2010

- Location

- Lebrina

- Posts

- 1,099

-

18th September 2011, 09:05 PM #15

Tool addict

Tool addict

- Join Date

- May 2008

- Location

- Perth

- Posts

- 164

I think I really need to attempt to take a video of what's happening.

The other night I did a bit of looking. Cable at the gun end is fine, nothing seemed loose.

Not sure about the gas flow - When it's on ~15lpm, should I be able to feel a good breeze coming out of the cup, or just a little bit?

Also, I had thought I had it running fairly well, in that a proper arc was happening, laying a bead, getting good heat, though the bead had a dull grey appearance much like what happened to someone TIG welding recently, and the wire brush wasn't removing it for me.

But I changed voltage, and it went back to stuttering arcs/no arc and just making the wire really soft.

The most frustrating part is that the fellow at the repair place said everything measured fine, and it was welding well. I'll have to give him a call tomorrow and confirm that that was also on the low voltages.

Though I wonder if he only measured the voltages, and nothing else, and didn't try all the settings, though he really didn't come across as a callous lazy person.

Similar Threads

-

Transmig 350 EC

By telnz in forum WELDINGReplies: 13Last Post: 16th August 2011, 09:26 PM -

Transmig 200

By quercus in forum WELDINGReplies: 5Last Post: 11th December 2008, 09:17 AM -

Troubleshooting Delta 46-715 noise !

By tonysa in forum WOODTURNING - GENERALReplies: 11Last Post: 3rd July 2005, 09:34 PM -

Bandsaw blade troubleshooting

By Rod in Ontario in forum BANDSAWSReplies: 1Last Post: 12th April 2004, 11:02 AM