Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 46 to 60 of 145

-

20th August 2015, 07:38 PM #46

Update

Update

I have been contemplating a major problem, I can confirm that my machine is a Waldown 8SN Series 1 made 1962. Brobo tells me that my machine is most likely one of the first machines ever made by them. These machines were all imperial before Australia made the shift to Metric shortly after. My machine should really belong in a museum of Austrian industry.

The problem I am having is that replacement parts for the machine no longer exist and Brobo does not make them. All attempts to fit new metric parts to the old imperial castings is not viable since there are small but measurable differences.

In particular I am in need of a new imperial spindle with a morse taper No.2. The old one was damaged in the morse taper.

I am now seeking to find someone to machine me a new imperial spindle.

My only other option is to replace the cast iron drill press head with a metric version and purchase a new metric quill, spindle & upper sleeve etc. In essence turning my Waldown 8SN Series 1 into a Frankenstein machine.

-

20th August 2015 07:38 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

20th August 2015, 07:55 PM #47

Could you not get the morse taper honed to remove any burrs or re-machine the morse taper and maybe reduce the length my 1-2mm?

…..Live a Quiet Life & Work with your Hands

-

20th August 2015, 09:17 PM #48

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

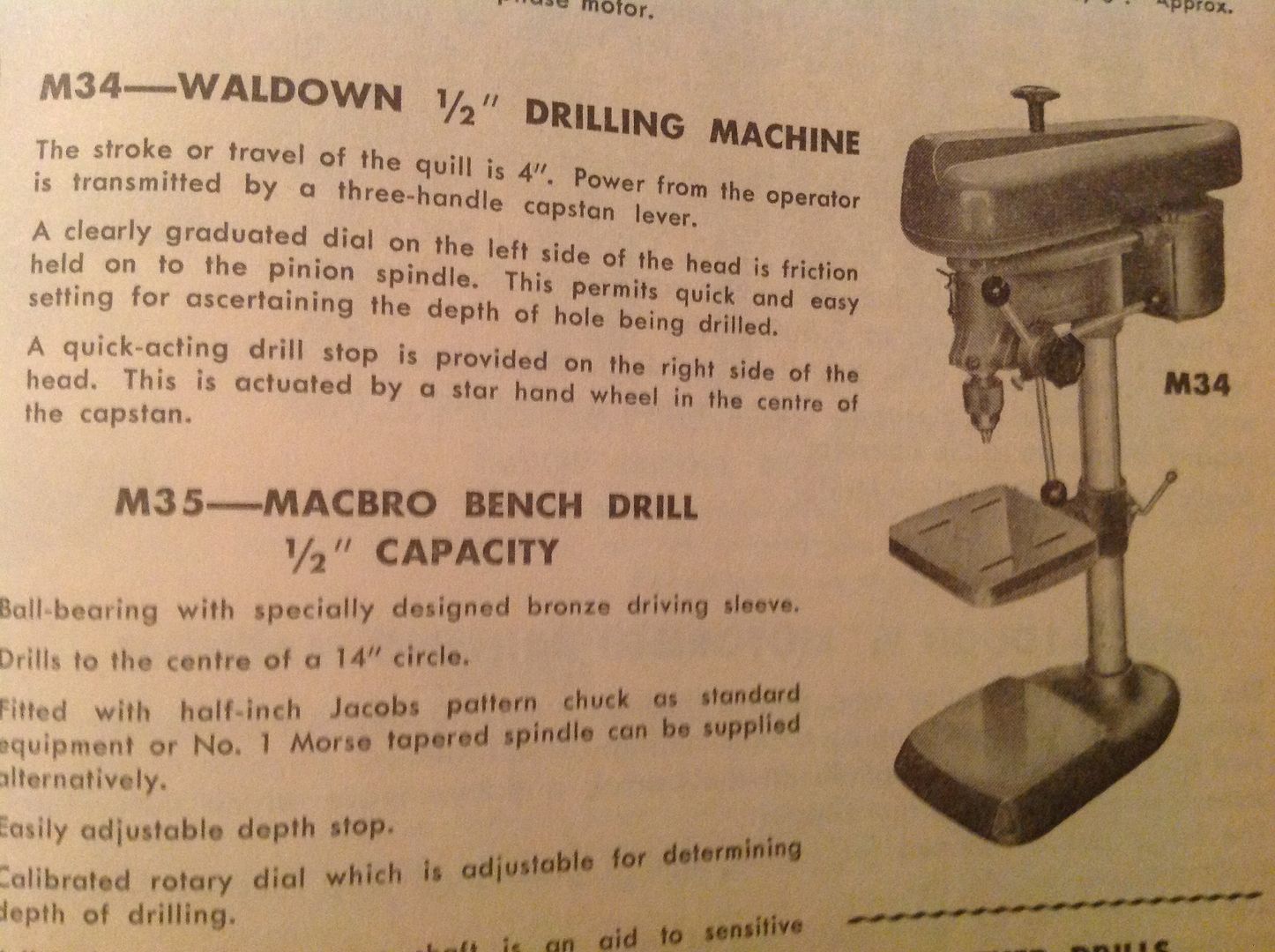

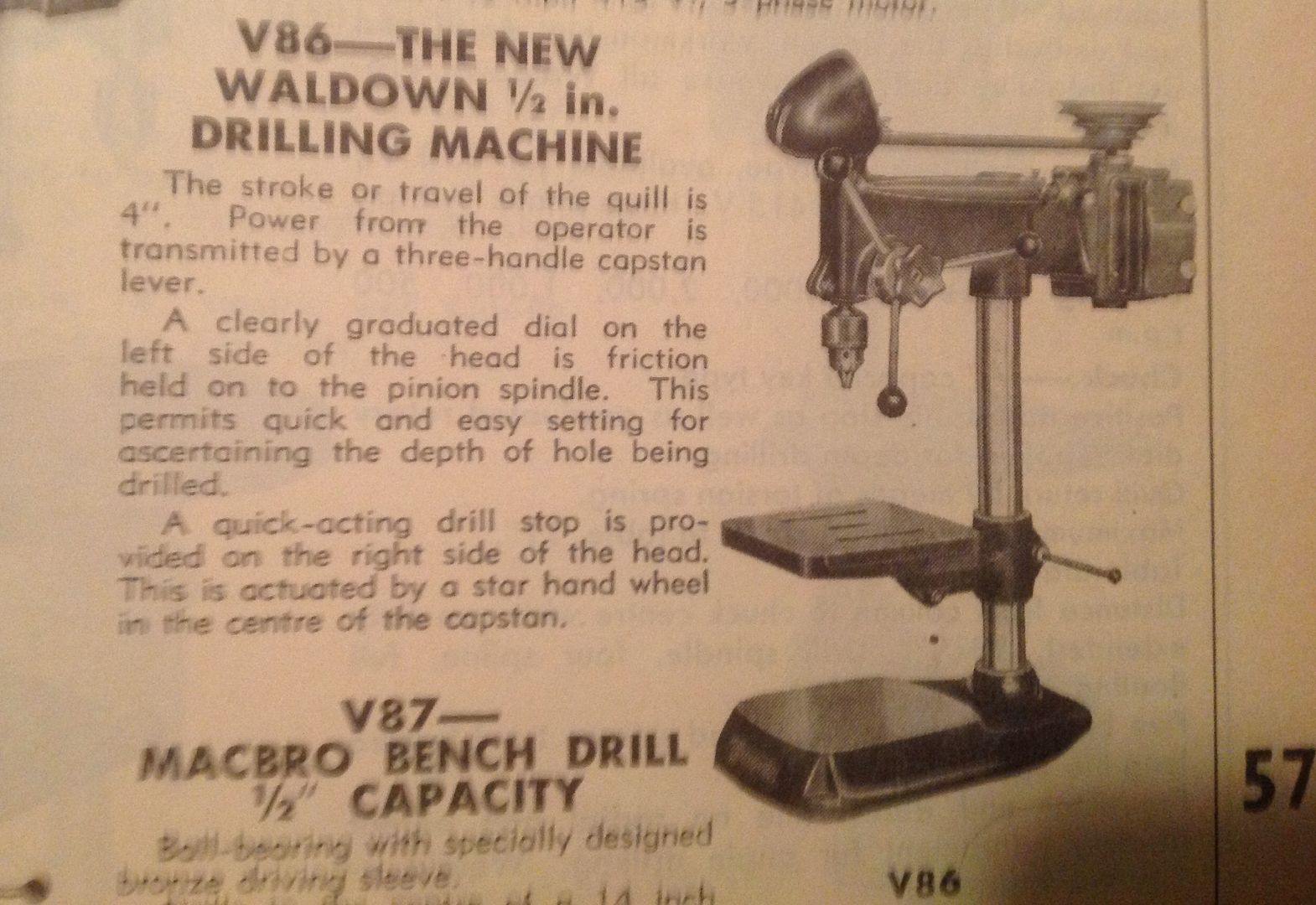

I'm no expert on Waldown 8sn's, is this one? I think so

If so, this is from a 1960 catalogue, so there dates are either off, of they wer making them earlier

In a 1951 catalogue there is this Waldown drill press:

interestingly has the same stroke of travel 4". I wonder if this might be the same quill?

My point isn't to debunk what you have been told, but hopefully to offer some hope.

It all depends on how patient you can be. The main reason I have a few Waldowns is because although they do go for high prices, they also sometimes go for practically nothing, to the point that I needed 2 handles and ended buying a drill press for less than I could have had the handles made, or bought as spares.

Perhaps if you have time, seek out owners of early 8sn's confirm if there are other imperials, perhaps ask sellers to measure as they come up for sale.

If your desperate to get it up and running, perhaps you could make a Frankenstein, and then seek out a parts machine in imperial so eventually you have an all original machine

Cheers,

Camo

-

20th August 2015, 09:57 PM #49

DSEL74 the morse taper part is gone, cut off, so a new part is needed.

I asked over at the metal working forum if a new metric spindle could be machined down the the imperial since the imperial is smaller. The answer was no, since the spindle is case hardened it would require a lathe with a grinding attachment, and it would be hard going to even remove the 0.2mm needed in places.

camoz - The first one is a almost exact replica of mine, except it does not have the knob above the sheet metal enclosure, and the enclosure is more rounded towards the front top edge, not having that square protrusion. The metal label on the side of the machine says "The New Waldown 1/2" Drilling Machine"

Screen Shot 2015-08-20 at 9.02.43 PM.png IMG_4602.jpg IMG_7589.JPG

I am in no mood to start a collection of Waldowns. All I need is one part the spindle and then I can start drilling.

I sure hope this thing does not become a 150kg paper weight.

-

20th August 2015, 10:08 PM #50

As a side point, I was wondering why no one has complied a history of Australian made machines. I think there would be lots of interest in the history and evolution of Waldowns, Turner, Pope, Woodfast, & Titans. Since there is allot of pride in these machine / tools and they are real slice of Australian history.

-

21st August 2015, 01:24 AM #51

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Taking a step back to understand. If you were to find a parts machine in metric, and took this part out of it

Even going as far as swapping out the pulley spindle and pulley if necessary, what would make this not fit and work in your existing head (remembering I am not privy to your full journey, so I apologise if you've already covered this somewhere)?

I ask as my parts machine (8SN)

became a quill donor for my Waldown Radial Arm drill,

it's quill was broken

it now has the 8SN quill

I dont think you need to start making a collection of Waldowns, but I wouldn't dismiss the idea of seeking out a parts machine, using what you need and then either selling or donating the rest (trust me when I say the parts I have used off this parts machine have worked out very very cheap)

Cheers,

Camo

-

21st August 2015, 02:58 AM #52

Here is another wild suggestion that I know is possible: take the spindle out, weld on a piece of 1-1/4" steel bar - properly, full diameter weld after proper preparation - and find someone with a lathe to clean the bearing seat, drill, bore and ream the end to MT2 and put your drill press back together. The morser taper end of the early Waldowns was not hardened. I don't know about the Brobo ones and I don't know about the spline part either, but I do know that the two Waldowns I owned were not hardened at the business end.

Cheers,

Joe

9"thicknesser/planer, 12" bench saw, 2Hp Dusty, 5/8" Drill press, 10" Makita drop saw, 2Hp Makita outer, the usual power tools and carpentry hand tools...

-

21st August 2015, 11:07 AM #53

camoz:

I bought a new metric spindle and found that it did not fit the imperial upper sleeve, so we bought the a new metric upper sleeve, now that does not fit the cast iron head. There is a 0.3mm difference between the imperial upper sleeve and the metric upper sleeve at the point of the ball bearings. Also the imperial quill is much smaller then later metric version. So the new metric spindle is wider and again there is a problem of metric versus imperial.

QUESTION & IDEAS

IF I could get ball bearing that was 0.3m bigger in its outer dimension (IMPERIAL) yet retain the same internal dimension (METRIC) the new upper sleeve would fit the cast head. Can I get ball bearings come in such a configuration / option? IF I can then it would be a simple task to make the new metric component fit the older imperial castings / components.

OR

The other option would be to purchase a piece of steel tube with a wall thickness of 0.3mm, in essence creating a jacket or sabot to fit the bore. This would allow the metric upper sleeve snuggly fit the imperial head casting. However this would not solve how to connect the spindle to the quill.

There is an eBay sale for this near me -

http://www.ebay.com.au/itm/Waldown-D...item43e131df1a

I could salvage the handles which I need but would the morse taper be a 1/2" spindle or something smaller?

JHovel - that s not a bad idea but it again boils down to find someone is willing to do such machining.

-

21st August 2015, 11:26 AM #54

Senior Member

Senior Member

- Join Date

- Dec 2013

- Location

- Sydney

- Posts

- 139

Thumbsucker,

I have nothing to add to the suggestions already made. But if you get that drill on ebay I'd like to make an offer on the spindle pulley. I need one to repair a second Waldown that I've recently bought.

Graham.

-

21st August 2015, 11:33 AM #55

Senior Member

Senior Member

- Join Date

- Dec 2013

- Location

- Sydney

- Posts

- 139

I've never heard of mixed metric/imperial bearings, but they may be available. However, can you consider making a thin cylinder to sleeve the metric bearing out to inch size? The 0.3mm wall thickness would be a challenge, but I can think of a few ways to do it, most likely involving Loctite 680 on one of the interfaces.

Graham.

-

21st August 2015, 12:26 PM #56

Could you buy some 0.3mm brass shim stock and wrap it around to form the sleeve?

…..Live a Quiet Life & Work with your Hands

-

21st August 2015, 06:27 PM #57

DSEL74 & Oldbikerider - I think you missed this part:

A sabot - "a device which ensures the correct positioning of a bullet or shell in the barrel of a gun, attached either to the projectile or inside the barrel and falling away as it leaves the muzzle."

I think this solution would solve the upper housing slop.

If we could find the imperial to metric ball bearings then I would be set.

However I am coming around to the option of salvaging the parts from another machine seems tempting. It would mean I would not have a Frankenstein machine and I would not have to jerry rig a solution. The problem then is to find a machine cheap then I need to get rid of remnants of the second machine.

-

21st August 2015, 08:33 PM #58

I decided to bid on the small Waldown, as the nameplate says it was a 1/2" machine, so I assume that the spindle should fit mine. I bid $125 but somehow I lost, even when the highest bid was $123. ??????

I think finding another Waldown to strip for parts is going to be the simplest solution. Buy Waldown, strip out the parts I want and sell the remains to others.

While a new custom replacement 1/2" spindle would be great. I doubt this is within the capacity of anyone to make. This only leaves salvaging old parts from another machine.

-

21st August 2015, 09:28 PM #59

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

I was looking at your spindle and comparing with the spindle on my one, it appears to be different and mine matches the one on the machine you missed, unless I am misunderstanding something (so perhaps it may have been a good thing you missed it). Yours has a morse taper female end, but mine ends directly with a JT6 taper (the JT6 taper is part of the shaft, and was what was sheared off on my radial arm drill).

This is from Ray's (RayG) rebuild of a 8SN series 3. Your spindle I think looks more like this one:

and mine and the one in the listing you missed looks more like this one:

So are these 2 different spindles? Or a JT6 male to female Morse taper adapter on yours? Hopefully if they are 2 different spindles, they are both the same size.

Cheers,

Camo

-

21st August 2015, 09:38 PM #60

Camo - Looks like you are right - good thing I missed out.

So it looks like I will need to get a 8SN series 1 to 3 1/2" morse taper.

I am sending the metric spindle and metric upper sleeve back to Brobo they will reimburse me the cost. I will then take the $400 spent on them and use it to find another way.

What are my odds of finding just a spindle if I posted a looking for spindle thread either in the market or in the general woodworking section?

Similar Threads

-

Help me get to know my new (old) Waldown drill press

By wsal in forum GENERAL & SMALL MACHINERYReplies: 13Last Post: 1st October 2014, 05:30 PM -

Waldown drill press

By eskimo in forum EBAY, GUMTREE, AMAZON (and other sale sites) Metalwork ONLYReplies: 1Last Post: 10th September 2014, 10:55 AM -

Waldown drill press

By camoz in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 8Last Post: 26th January 2013, 10:15 PM -

Waldown Drill Press

By KevM in forum METALWORK FORUMReplies: 24Last Post: 1st September 2011, 01:31 AM -

Waldown drill press

By mikm in forum GENERAL & SMALL MACHINERYReplies: 5Last Post: 17th August 2009, 10:35 AM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote