Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 106 to 120 of 173

Thread: Cool stuff

-

25th July 2013, 07:02 AM #106

Yup. Your first home roast is a one-way ticket. You never go back to store-bought. I went down that road 5 or 6 years ago and never looked back.

That said, a certain amount of my coffee habit is due solely to caffeine addiction. I'll drink any kind of campfire coffee after a night in a tent. Christophe's machine looks mighty good to me.

-

25th July 2013 07:02 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

25th July 2013, 08:13 AM #107

Hehe, this is a nice distraction as it's another obsession of mine! Joost, I'm afraid that you won't find such a machine as stove-tops just get too hot to be ideal. To achieve higher pressures in these machines you have to apply more heat which is not desirable. I have an old Bellman with a pressure gauge that I use every now and again, and then I put it away. It can get to 5 Bar but the problem is the temperature is then too high so it over-extracts. Ideal temp for extraction is only 91-94degC so a stovetop won't be able to achieve ANY pressure at these numbers. The only consistent way is to regulate the temperature of the boiler and then use a pump to achieve the correct pressure which is what a good machine does accurately and reliably, although somewhat more expensively! A manual machine such as Dan's HandPresso can help you get get closer to the ideal temp and pressure numbers, and this why they do such a great job.

CX-25.jpg

-

25th July 2013, 05:13 PM #108

Thankyou hugely Joost ... but I have a weird problem.

I just didn't get the coffee gene. Parents had spent so much time in Europe before they met that we were well up on the coffee appreciation in the '60s (a cultural desert in Oz) when the only place to get a decent coffee was at a Milk Bar run by Greeks or Italians - or DIY.

But despite my exposure and dabbling (even a phase of drinking of that thick Lebanese coffee) its always been the same situation.

I taste and "Meh". It is really strange and frustrating ... I like good cafes ... but I sip and ... nothing.

That goes for all types.

Coffee only comes into its own for me in desserts. Tiramisu or simple coffee cake with coffee icing ... need something for it to contrast against ... black coffee with cream floating on top isn't bad ... but my waistline and arteries.

Just don't have the coffee gene.

MIK

-

25th July 2013, 06:48 PM #109

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2008

- Location

- Tilburg, the Netherlands

- Age

- 51

- Posts

- 519

MIK,

If that is the only weird problem that you have, you are okay.

Bruce,

I have Quick Mill 820 at home which is sufficient for my needs. I like a decent coffee, but I must admit that I cannot be bothered to roast my own beans and to make my own grounds. But then again, a lot of it is roasted in the Netherlands with very short distribution lines to the speciality shops where I buy the grounds.

I know that the Brikka will never accomplish what my home machine does (lacking the pressure at 3 Bar and too high water temperatures), I am just hoping (hopefully not in vain!) for a bit better brew when camping or otherwise on holiday (pressure 1.5 Bars in comparison with the Moka and the promise of slightly lower temperatures).

My brother by the way always takes his home machine with him when going on holiday, not being able to live without it!

Joost

-

25th July 2013, 07:42 PM #110

-

26th July 2013, 09:10 PM #111

-

31st July 2013, 06:30 PM #112

3D Printer

3D Printer

At our local shopping centre today I saw a 3D printer in action for the first time. Engineering students were designing all sorts of cool stuff and then printing them out. I've seen them in videos, but never for real. They are simply amazing. It was similar to this one, which is just a baby compared to the big industrial ones

3DPrinter.jpeg

Ok, if you could have one of these in your shed, what boat stuff would you print?

-

31st July 2013, 11:59 PM #113

My son has one. A Reprap Mendel (open source, homemade). I can't say that I've found any real use for it yet. Maybe that's a function of my lack of imagination. Cool toy, though.

Sent from my cell. Please excuse typos and brevity.

-

1st August 2013, 01:47 AM #114

Probably no boat stuff. But I would certainly make various brackets and trim pieces for my car if I had one. For instance, I've wanted to replace the inadequate fog lights (simple round lamps) with high quality Hella torches. To do so, I have to reconcile the differences in the mounting bolt patterns. An intermediate bracket that fits both the bumper and the new lamps is easy to design on paper/monitor. But fabricating two of them has challenged my limited resources (and sometimes shaky hand). If I could just hit PRINT and have an exact part pop out...

Maybe we should be 3D printing the flying cars we were supposed to be driving by now...?Dave

StorerBoat Builder, Sailor, Enthusiast

Dave's GIS Chronicles | Dave's Lugs'l Chronicles | Dave's StorerBoat Forum Thread

-

1st August 2013, 02:40 PM #115

In general you can make patterns or moulds that can then be used for moulding some more usefully strong materials like the better plastics and metal.

There's a nice video of a sophisticated design of a bicycle being printed as one process from bottom of the tyres to the tops of the handlebars.

It is absolute crap to ride of course.

Just found the video

The problem is looking at one simple bit of boat gear - a simple six dollar block from ronstan.

The sheave is delrin or nylon for light weight and low friction on a simple bearing. The cheeks are a single piece of 316 stainless sheet, pressed to make it stiff - minimal working so a standard grade can be used. The rivet is probably a different grade of stainless steel - it tends to work harden easily so forming the rivet ends and then loading it as a block might require a more malleable or machineable grade of stainless. Finally the top is swivelling - two similar metals tend to bind if they rub against each otehr much and the inside part of the ring is upset heavily (flattened) so it won't pull out of the hole in the sheet.

That's the problem ... different materials for different purposes with different characteristics to make a cheap ubiquitous block that is very strong - much stronger than their ball bearing blocks.

Think of a 3d printer - it spits little bits of resin or a powder that is melted to other bits by laser or several other methods all producing a quite porous material that is surprisingly strong for handling ... but will fall over in most real tests.

I think the question is "what CAN you make with rapid prototyping (its other name) that is strong enough for a boat?

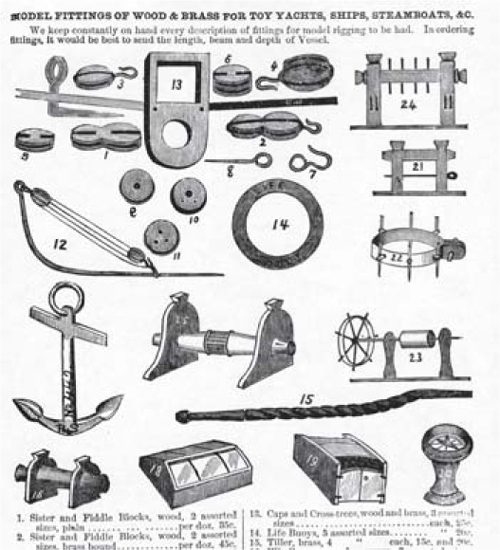

But what is exciting the chance to recreate stuff from old boating catalogues ... some was really beatiful, some cute. Then use the pattern from the printer to get something cast.

Model yachts

Real yachts (though cheaper to buy these from current makers)

I've no idea what this is

or this bit

MIK

-

1st August 2013, 09:27 PM #116

Mik, on the high end printers, they are capable of different materials, though you need lots of cash for these babies.

I can see a 30' long, 10' tall printer punching out 25' raw hull shells, with liners and deck caps in place, in the not too distant future. Perfect laminates of absolutely appropriate thickness for it's location, etc.

I hope I'm dead by then.

-

2nd August 2013, 01:52 PM #117

Nah Paul ... no need to fret.

Plastic is terrible stuff to build boats of - it is flexible, soft, heavy for the strength, not particularly tough.

Composite building is the answer .. and there we know the secret is ... fibres.

What sort of fibres?

Well, we can take 2 or three inch ones randomly oriented - and we know that such construction needs to be thick and heavy to be strong enough - and it is kindof flexible. It is quite tough because of the synergy of the weak resin and the strong fibres creating automatic crack stopping behaviour. They had a crack at building railway carriages of the stuff in the '60s and found it flexed too much for the doors to open.

So then we see continuous fibres are the solution. So a system that lays out continuous fibres and a plastic matrix at the same time in a 20 or 30 or 60 foot printer? Nah.

The other factor is the printers - to get the resolution have to work pointwise - whether sintering a powder using lasers or the molten inkjet method - how many DPI in a 30ft by 10ft by 8ft hull?

THEN there is the finishing problem. One of the economical factors of conventional boat moulding is that you end up with a finished surface that requires no painting. We know from wooden boat building that finishing is a big part of the building - something like 20 to 50 percent of building time depending on different factors. This will be the case with inkjet boats.

There's some bloking talking about using the tech to make steaks out of algae - ink jetting the components together in a nano structure. He's obviously spent very little time cooking in a kitchen - probably thinks custard comes out of a cardboard package - eeeeeuw!

MIK

-

2nd August 2013, 05:48 PM #118

I think you can engineer plastics to do about anything, including light, stiff and strong structures. It's likely a day will come, where the need for fibers in a resin matrix, will be unnecessary. We're getting close to this now.

Though I prefer wood, plastics (with fibers) do make fine boats, as do metals. In fact, my ideal material for a hull would be monel, with aluminum internal structures and cabins, with a good bit of this skined in a veneer, of several of my favorite species. I have a 65' production yacht that's only 11 tons lightly loaded and carries nearly a 50% ballast ratio. This would be very hard to do in wood or metal, including aluminum.

I've found each hull material choice, has a range where they're most effective, from several vantage points. Wood is hard to beat in smaller sizes, when everything is considered, particularly cost to weight ratio.

I also think we'll print food before more complex structures come along. As unappetizing as this sounds, it's pretty easy to fool the mouth and other senses.

-

2nd August 2013, 08:50 PM #119

Sorry, can't go sailing this w/e coz my printer ran out of plastic and Cartridge World don't have any more midnight blue in stock, so my boat won't be ready.

But I should be ok for next w/e. You bring the beer tablets and I'll print some more burgers for the crew. By the way, are you bringing android Wendy again? She's such a hot winch wench!

Sent from my iPhone using Tapatalk

-

2nd August 2013, 09:11 PM #120

Sweet God, we coming to it, I'm afraid. I'm glad I'll be dead, but we have the beginning of this, in many regards now. It would be nice to live long enough to see the android wench though.

Similar Threads

-

How cool...

By Sigidi in forum SMALL TIMBER MILLINGReplies: 14Last Post: 4th November 2009, 01:28 PM -

Cool vid

By Sebastiaan56 in forum WOODTURNING - GENERALReplies: 2Last Post: 20th June 2007, 11:12 AM -

cool pen

By ss_11000 in forum WOODTURNING - PEN TURNINGReplies: 7Last Post: 13th April 2006, 11:19 AM -

So cool

By Grunt in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 8Last Post: 11th February 2006, 07:06 PM

Likes:

Likes:

Reply With Quote

Reply With Quote