Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 64

Thread: Thoughts about a CNC

-

1st November 2009, 09:24 AM #1

Thoughts about a CNC

Thoughts about a CNC

I'm a bass guitar builder and want to get into CNC. I've done a lot of research over at cnczone a couple of years ago and read this forum every once in a while. It's time for me to start building my own (slowly) but before I bust my chops spending all my little spare time building one (I usually use all my spare time away from work building basses!), would any of you gentlemen know if there's CNC's available in Australia under 3k (not counting software, just table) that would have a cutting area of 1000mm X 500mm X 100mm. If there isn't then I'll build mine

I'll start slowly drawing up my plans in Inventor or Rhino (just bought Rhino last week) and get back to you guys with my ideas and would be happy getting criticism on it. I'll use this thread as my main design/build thread/questions thread for all the stuff that pops up my my head

Ok so apart for available cheap commercial CNC in Oz, here is my other question. I have a Bosch GOF1300 router I plan on using on that CNC. What's all that talk about collets (ER20, ER11 etc..) and would some collet fit to my router? I understand that the collets are for using different diameter bits but do all collet fit to normal routers? Is it just a matter of changing your normal router collet to that? and are these collets easier to change bits than a normal router collet during the operation of the CNC?

-

1st November 2009 09:24 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

1st November 2009, 10:04 AM #2

Senior Member

Senior Member

- Join Date

- Nov 2008

- Location

- Far North Queensland

- Posts

- 330

Hi Phil, have you seen my latest build log on CNCZone ?

The design for that was done by a mate of mine that is thinking of doing a "flat pack" kit I guess you would call it. I just happen to be the guinea pig for the prototype

The idea is that he cuts it all out of 16mm ally plate on his VMC so everything is square and you just bolt it together and add your linear rails/ballscrews/electronics etc.

Sorry but it may be a few weeks or more before we have motion but feel free to check it out and see what you think. Also being the prototype we have to iron out the bugs as we go. So far it is looking good though.

No set idea of price yet, obviously doing a one-off is more time consuming but once it is sorted the target price for the aluminium work only is about 2K. As I said it only at the "thinking" stage right now so they won't be getting churned out this week, but depending on the final result of mine possibly early next year...

Cheers.

Russell.

-

1st November 2009, 12:51 PM #3

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Feb 2008

- Location

- Australia

- Posts

- 988

There use to be one bloke who use to make them but he closed up shop, wasn't as big.

You might be able to grab something from the states (on ebay) but postage will cost quite a bit. The exchange rate is quite good now also.

-

1st November 2009, 04:20 PM #4

Thanks guys, I don't think I'll go the US Ebay route for a full machine, too expensive and too much $$ for shipping it here. I already looked at some of the smaller CNC's in the US and they're either too small or too expensive for me. I'm not ready to pay more than 3k AUD for one. Looks like the homemade CNC route is more for me.

I just had a look at your CNC Epineh, it's the Banana Bender one right? I didn't read the whole thing but have looked at some of the pics. I'm more curious to see the finished product right now I want to start on the design ASAP, not patient enough to wait to see if he'll offer his as a flatpack. I'm planning on starting the build after x-mas.

I want to start on the design ASAP, not patient enough to wait to see if he'll offer his as a flatpack. I'm planning on starting the build after x-mas.

I'd like to keep my table at under $1500, not counting motors or controller. I know our Chinese ballscrew and linear bearing man will cost me about $700 for all 3 axises. So I've got about $800 leftover for some t-slot extrusions, bolts & nuts, etc... I want to make it as basic as possible and have as little holes to drill as possible. For that price I probably won't be able to afford 8020 everywhere but a few key place will probably work. I still have a lot to think about.

I like this K2CNC design, any reason why that wouldn't work on a 1m X 0.5m cutting area?

-

1st November 2009, 04:49 PM #5

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2003

- Location

- Perth WA

- Posts

- 3,784

Hi Phil,

A couple of points

That design has a lot of CNC machined parts so it is probably out of range until you build a machine.

The span on Z axis (the longest axis) limits the length of your machine with this design. If you want to go with 1m cutting you are probably looking at 1200 span (allows for bearings) which is a bit much unless you can support it underneath or use larger side members. The under table joiner to pick up the ballscrew is the reason for this. Either beef up the sides so it will support the span or go dual ballscrew.

I use 150 or 200 by 6 steel plate on edge to overcome this on my machines. I have also used dual screws. I am not sure what spec you would need to go to do it in 8020 but John is in the process of making a machine with 8020 or Item so check that out.Cheers,

Rod

-

1st November 2009, 05:23 PM #6

With this k2cnc design, I was thinking of using 6060 metric extrusion which would make a 30mm spacing for bolting the SBR16 rails to each side, the holes are 30mm apart on each side of the rails.

Would that be solid enough for the 1200mm span? Could the table be reinforced by adding two more extrusions in the inside length of the table on each side of the ballscrew?

EDIT: could you point me to John's thread or his username please

Second EDIT: I'm a moron and a blind bastard, forget about it, I found it

-

1st November 2009, 07:43 PM #7

Senior Member

Senior Member

- Join Date

- Nov 2008

- Location

- Far North Queensland

- Posts

- 330

No probs Phil, yup Banana Bender is the one

If you want to go sooner rather than later then definitely don't wait for us, it is a side project at the moment and things seem to go a little crazy this time of year so progress will be slow and steady.

Hope your build goes well and I will help if I can.

I see you are in Brisbane, I believe the guys down that way are having a CNC BBQ in November if memory serves me right, it would be worth your while to drop in and have a look.

Cheers.

Russell.

-

1st November 2009, 09:58 PM #8

Senior Member

Senior Member

- Join Date

- Dec 2007

- Location

- Melbourne

- Posts

- 105

Russell,

Have you got a link to the CNCZone build log you made mention of in post 2?

R/-

Grant

-

1st November 2009, 10:08 PM #9

Senior Member

Senior Member

- Join Date

- Nov 2008

- Location

- Far North Queensland

- Posts

- 330

Hi Grant, here ya go :

Another Banana Bender's Build !!! - CNCzone.com-The Largest Machinist Community on the net!

As I mentioned it will probably be a slow build, my first one took two and a half years...lol hopefully this one is a little quicker

Russell.

-

2nd November 2009, 04:37 PM #10

Senior Member

Senior Member

- Join Date

- Dec 2007

- Location

- Melbourne

- Posts

- 105

Russell,

I have read through the CNCZone thread - very impressive. I will keep an eye on your progress. Hopes the build goes well.

Grant

-

28th November 2009, 04:16 PM #11

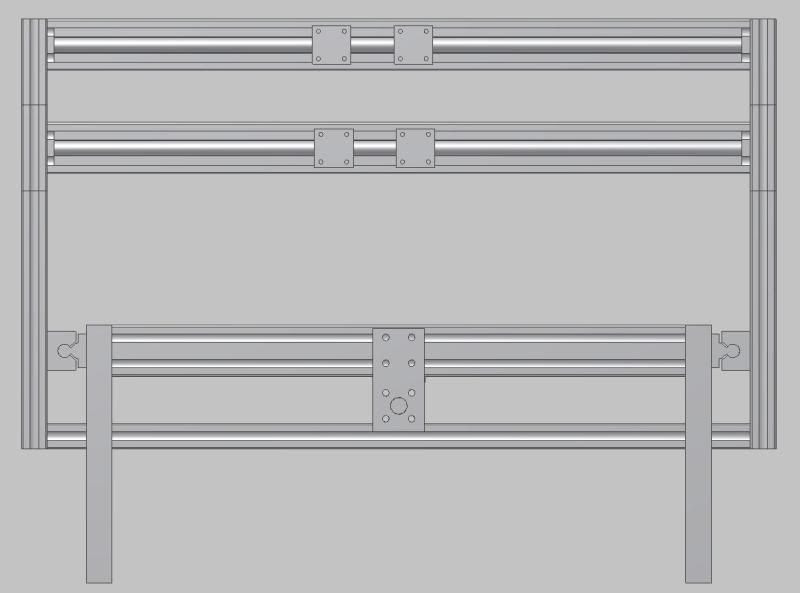

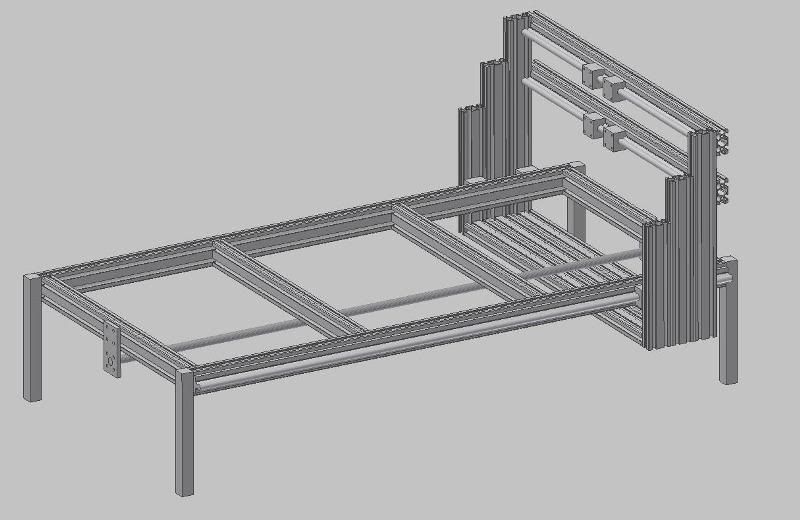

So I ordered X and Y linear rails from Chai, 1400mm and 800mm. I started the design of the machine in Inventor 3D. I'd like to thank Nismo for his great looking CNC which has given me plenty of ideas for my own CNC. I was always interested in building an 8020 CNC but always though the extrusions would set me back 1k (too much $$) thanks to the link he found (AME System | Workstation systems for efficient workplaces) it looks like the extrusion will only cost me $400 for the whole build

I designed the whole machine using 3060 extrusions and designed it specifically to fit the rails I bought (SBR16's). The gantry sides wil be made from three lengths of 3060, so 180mm wide. Once the table is built I'll simply bolt a thick sheet of MDF on top of the table to use as the table and stiffen up the table.

Now that the whole thing has been designed to size, I'll be ordering my extrusions cut to size from AME system At this point I'm still not sure what the carriage will be like. The extrusions and the rails will keep me busy for the next month or two. I'll order the ballscrews and Z axis rails when I have a bit more pocket money. I'll probably come up with a carriage design in the next month or so as I build the CNC

At this point I'm still not sure what the carriage will be like. The extrusions and the rails will keep me busy for the next month or two. I'll order the ballscrews and Z axis rails when I have a bit more pocket money. I'll probably come up with a carriage design in the next month or so as I build the CNC

The brackets that hold the ballscrews and carriage parts will likely be built out of MDF or particle board and once the CNC is ready to go I'll rebuild these parts out of Aluminium.

-

28th November 2009, 10:23 PM #12

Phil how much did Inventor 3D cost you.

Davidgiveitagoturning @hotmail.com

-

28th November 2009, 10:40 PM #13

Nothing, it's a student edition I got when I was at TAFE a year ago. Autodesk has a student community where you can download a whole lot of their latest version software. They're usually 16 month licenses but when that expires you can pretty much download the latest version and go at it again. I graduated a year ago (and they know that) yet I can still download and use their software. Go figure.

I think a seat of Inventor is about 8-10k. It's not that great for the applications I use it for anyway. It's good for engineering applications but very hard to design compound curves with it like most art programs will let you do. That's why I bought Rhino to design my instruments. I'll have to take the time to learn it though

-

29th November 2009, 01:05 AM #14

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Feb 2008

- Location

- Australia

- Posts

- 988

Maybe look at beefing the X axis aluminium up a bit as it will be taking most of the load.

Then again I think 80x80 Heavy is too weak for a 1200mm span.

The base of the gantry to which the Ballscrew will attach to, isn't 3 lengths a waste of money? A right angle joint or plate should suffice?

Just some food for thought.

Regarding custom cut parts if aluminium look at getting them waterjet cut, might cost a little fortune but its cut accurate and will be hassle free if you get everything done at once it might only cost you a few hundred depending where you go. Then again this is if you are hopeless at woodwork like myself.

If you get aluminium cut to size make sure they use a digital stop, eye sight is only accurate to so much, reason why I love 8020* as he uses a Digital Stop which is 0.1mm accurate + he just got a new machine.

*wish they stocked 120x80

-

29th November 2009, 09:16 AM #15

I'm hoping that the combination of the 3060 extrusions on the sides + the X rails bolted all along the sides + a thick sheet of MDF bolted all around the top for the table will bring the deflection down to a bare minimum. I'll cross my fingers on that one

I'll probably check the deflection with a straightedge on the X axis during the build. If it's more than I like then I'll have to think up something else.

I'll probably check the deflection with a straightedge on the X axis during the build. If it's more than I like then I'll have to think up something else.

I'd rather keep the cash than pay for custom parts. My woodwork skills are pretty allright, it won't be a problem to fix up a few pieces here and there until the machine runs and replaces these parts. I'm getting excited already

Similar Threads

-

Your Thoughts On This

By Ed Reiss in forum WOODTURNING - GENERALReplies: 8Last Post: 5th March 2009, 08:57 AM -

your thoughts please

By kmthor in forum DESIGN & DESIGNING / GOOGLE SKETCHUPReplies: 5Last Post: 6th July 2008, 10:18 PM -

thoughts for the day

By Ivor in forum WOODIES JOKESReplies: 0Last Post: 5th June 2006, 11:57 AM

Reply With Quote

Reply With Quote