Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 18

-

12th November 2013, 10:21 AM #1

saisay Chinese machine conversion

saisay Chinese machine conversion

Hi saisay

I have only looked at the Shark machine from afar, so I have no direct knowledge of the setup. However, all the CNC machines that use stepper motors are basically the same.

So, the first thing you need to do is to remove the motor connectors where they go into the control box and then re-terminate them with the Gecko DB9s. To do this, you need to first find out what the A- A+ wire pairs are, and then the remaining wires will be the B- and B+. Connect them to the DB9s as per the Gecko instructions. If you get the pairs mixed up and think that As are Bs it doesn't matter, because this is purely notional and a software setup.

The correct pairing can be determined by first stripping the four wires so that you can connect them by hand. Turn the idsconnected shaft by hand so that you know how much effort it takes to turn the unconnected shaft, then try (without connecting any power) connecting the black wire with the red wire and try again to turn the motor shaft by hand. If the shaft turns easily then connect the black wire with the blue wire and try again, then the black wire with the green wire. I have made a total guess at what your actual wire colours are and you may have pink, white, orange and purple for all I know. When you get significant resistance to the turning of the shaft by hand then you have found the correct pairs. If all the motors are the same size and type then it is likely that they will all have the same pairing.

If I err in my instructions at any time then I hope somebody will correct me ... graciously.

That is the end of the first step.

To be continued ...Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

12th November 2013 10:21 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

27th November 2013, 09:37 AM #2

OK

Here we go.

I have dusted off the Chinese 2040 and am ready to start.

On the CNC I have a female serial? plug.

The wires from the motors are soldered to this plug.

Pins 1-4 are left-right 2 red/2 blue

15-18 are up/down 2 red/2 blue

19-22 are backwards/forwards 2 red/2 blue

I call them that because I always get confused which axis is what

I am not sure I understand the shortening of wires on the motors without power. How does that stop the gantry from moving?

On the control/power box I already have 3 separate DVI? plugs for X-Y-X axis.

I would like to keep those as the holes are already in the box and it makes it easier to connect the cables.

It also already has a USB connection for the computer.

How do I find out which wire is what?

I don't want to blow up another box and computer

Thank you for your help Every day is better than yesterday

Every day is better than yesterday

Cheers

SAISAY

-

27th November 2013, 10:00 AM #3

Photos help heaps! They are also a record of what you had before you started to change things about. So, some good photos please.

We are not shortening the wires, we are shorting them. ie connecting up a closed circuit.

The motors should be disconnected and removed from the gantry drive system so that you can spin the motors by hand. After doing this, follow the instructions above to ascertain the wire pairs for the As and the BsBob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

27th November 2013, 02:33 PM #4

Shorten/Shortening, my kind of English

OK, I think I worked the motors out.

I still don't understand why this is happening when there is no power connected?

Easy01.jpgEasy02.jpgStepperMotor.jpgEasy03.jpgGrowling01.jpgGrowling02.jpg

1 =Easy 01

2= Easy02

3= Stepper Motor

4= Easy 03

5= Growling 01

6= Growling 02

I guess 5 and 6 will be the pairs you was talking about?

1 pair is red and 1 pair is blue.

This is the first time I have seen one of those flexing couplings.

I rather like them Every day is better than yesterday

Every day is better than yesterday

Cheers

SAISAY

-

27th November 2013, 05:16 PM #5

Hi saisay

I do not understand the names you have given to the motors. Growling? Who or what is growling, you or the motors. Where are you getting the colours from? You show a motor with a bare header and a bit of white wire across some terminals.If there are only four wires connected to the motors then you can safely ignore most of the following.

Read this site as well, that is someone who has already done exactly the same thing as you are now doing.

I have not seen connectors such as you have on stepper motors before.

Here is a picture of a normal 4 wire stepper motor that I am testing to find out which wires are pairs. The red and blue wires, when SHORTED together make it very difficult to turn the motor shaft by hand. That is because they are a pair and can be either A-andA+ or the B- and B+. P1030177.JPG

Some motors have 6 wires and your motors have 6 terminals. This makes it a little harder for you because ther are more possibilities. The other bloke says his motors are all four wire motors and maybe they are.

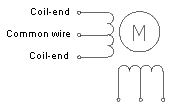

For any stepper motor to be wired up properly, you need to determine which wires are "pairs" or connected to the ends of each coil. These are usually referred to as coil "A" and coil "B", but which is which doesn't matter so much as you may think think.

This picture shows how 6-wire steppers are wired. 6 wire motors can be wired up as four wire motors by ignoring the centre tap(common wire) and just making the coil-end wires the As and Bs

Go through the motor a step at a time. Connect pin1 to pin2 test turning resistance, connect pin 1 to pin 3 etc up to pin 1 to pin 6 then start connecting pin 2 to pin3.

The full list of connections possible is:

1-2

1-3

1-4

1-5

1-6

2-3

2-4

2-5

2-6

3-4

3-5

3-6

4-5

4-6

5-6

I like the flexible couplings too. They are pretty.Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

27th November 2013, 05:51 PM #6

I don't know whether they are pretty but they do take the flex out of the screw, just in case the ends are a bit out of centre.

I haven't seen those connectors before either, they are fixed to the motors, then you just plug the wires in.

I guess that is the difference between Japanese and Chinese motors.

Sorry, the growling was an attempt at humour.

Squeaking sounded wrong, didn't how else to explain the sound when I tried to turn it.

Actually, the growling means the axle does not want to turn easily

The white wire was just an easier way of shorting the terminals as there are no wires, on each female connector are 2 pairs of red and 2 pairs of black wires that go down to the serial plug. There are 5 pins but only 4 are used.

Now I just have to work out which pin is which on the connectors already on the box. If I can use the board already there, then I can swap the Shark one on The Beast with the Gecko one and use Mach 3.Every day is better than yesterday

Cheers

SAISAY

-

27th November 2013, 06:43 PM #7

OK that sounds a lot better.

So what you are saying is that when you connect the two red wires together by hand then the rotor becomes harder to turn? If so, then that is the first pair of wires and the others must perforce become the second pair.

If that is so, then cut the wires where they connect to the existing plug and then solder them to the back plug from the G540, taking note of where they are meant to go. As I said before, there is no difference between A wires and B wires, it is just a handy convention.

Here are Peter Homann's instructions

Do the same thing for every motor.Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

29th November 2013, 08:56 PM #8

Just hit another snag.

Found out all the wires from the motors are aluminium

Very difficult to solder

Nobody locally had any aluminium solder.

Solved the problem by flushing both ends with solder, fusing them together and then covering the mess with shrink flex

Managed to get some shells for the RS232 plugs locally, no trip to Cairns needed

Anyway, ready for the next phase tomorrow.Every day is better than yesterday

Cheers

SAISAY

-

30th November 2013, 08:37 AM #9

Hi saisay

Glad you managed to work something out. But aluminium wires? They wouldn't flex more than a couple of times before they snapped. If you are certain that they are aluminium then I would suggest that you replace them with copper multistrand wire. I appreciate that you will be happy that you managed to solder to the aluminium, but a short while down the road when something unusual starts to happen you will be wondering what can possibly have gone wrong now. Ahem .. check the wires.

Bob Willson

Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

7th December 2013, 06:57 PM #10

Have you fallen asleep saisay, or did I tell you to do something wrong that accidentally killed you?

If the former then please answer on awakening, but if the latter ... don't bother.Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

7th December 2013, 09:18 PM #11

No,I am actually so peed off I didn't feel like socializing

Went to start up the CNC, accidentally touched the X-Axis cable, it was so hot I burned my finger.

Nothing wrong with the actual connection and nothing wrong where the wires from the motor is soldered to the cable, but the moulded part of the cable is very very hot.

I swapped the Z and X cables around and it was still red hot, so, thankfully, nothing is wrong with the box but one of the inside wires must have broken and is shorting out.

But I do have to wait to Monday before I can buy another cable, so annoyed.

I AM JINXED.Every day is better than yesterday

Cheers

SAISAY

-

10th December 2013, 11:06 PM #12

I am definitely freaking jinxed.

Got everything wired up and ready to test, then I realised the motor has a moulded male isolated power supply plug.

Can't buy its female partner in this country so now I have to wait for one from ebay.

You would think that if Jaycar sell the male they would have the female as well but no such luck.

Decided to start of the Beast aka Shark. Accidentally touched the x cable and burned my finger so I have to make a new cable. To work out which colour goes where I shredded the moulded RS232 plug. Turned out I can't blame Next Wave Automation on this one. Pin 1 had solder on it but no wire, found the wire but it had never touched solder. Pins 5, 8 and 9 all had their wires attached but also a big blob of solder that connected all 3 pins. Small wonder I have always had trouble with that machine. 9 is earth, 5 and 8 are paired.

You think I can buy a male 9 pin RS 232 plug in Tully. Not on your Nelly.

I AM JINXED

Some ramblings:

The catchcry in USA is

Buy American Made.

Some fanatics even refuse to buy things that are not American made.

Well, I wonder how many bother to look behind the label that says

Made in USA.

After taking the Shark apart I have found that at least 50% of the parts come from Asian countries.

At least in Australia we say:

Assembled in Australia from imported and Australian parts.

That's more honest as far as I am concerned

Even more surprised when I found the name of the shrink flex on the Shark cables has my birth name on it.

Investigating further I discovered that my enterprising "baby" brother in Denmark has a finger in the pie with that stuff.

It sure is a small world.Every day is better than yesterday

Cheers

SAISAY

-

11th December 2013, 12:12 AM #13

-

11th December 2013, 12:22 PM #14

Not at all, the name on the flex is Woer, a very old family name.

I am his godmother but we have not been in contact for years.

He has really moved upward on the social ladder by sheer hard work and tenacity and in the circles where he is moving, he does not like to be reminded of his humble beginnings.

We all inherited my mother's brains and he got the opportunity to use them to his advantage.

We were as poor as churchmice and he was the only one finishing school. He is the second youngest of 7 (only 3 of us left, one younger brother who is 20 years younger than me and a real bum) and by the time he reached high school, there weren't as many mouth's to feed and it wasn't necessary for him to leave school as soon as he could and get a job.

I admire him for using his education to his advantage and continue studying at his own expense.

He spent 37 years in IT, starting with Texas Instruments, every time he moved on it was for something bigger and better before starting out on his own.

If anything shows potential for making money, he will be there. He is an extremely clever man.

I guess he had acquired a lot of useful contacts during those years.

Well, that is a bit of family history, it goes a lot further than that but I think you have had a bellyfull by now Every day is better than yesterday

Every day is better than yesterday

Cheers

SAISAY

-

12th December 2013, 06:40 PM #15

OK saisay

You've had enough time now to get over the poor little me and I AM JINXED feelings and get back into some serious CNC remedial stuff. Have you got the new wire if so why haven't you told us that you have wired it all up?

Wassup?Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

Similar Threads

-

Need Help: New machine - G540 - 110V Huanyang VFD - Chinese spindle 1.5kW

By dubdzine in forum CNC MachinesReplies: 1Last Post: 24th June 2013, 01:22 PM -

United states machine tool co. #1 horizontal milling machine

By pmcgee in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 0Last Post: 1st March 2013, 11:16 PM -

Rebuilding Chinese Machine

By Ch4iS in forum CNC MachinesReplies: 28Last Post: 26th February 2010, 12:03 PM -

Convert manual machine into electric machine

By Tiger in forum COOKINGReplies: 4Last Post: 3rd March 2008, 01:47 PM

Reply With Quote

Reply With Quote