Results 781 to 795 of 1535

Thread: 2/3 scale Indian Straight Four.

-

14th September 2014, 12:59 PM #781

I reckon you'd churn out an MDF one in no time

Dave the turning cowboy

turning wood into art

-

14th September 2014 12:59 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

18th September 2014, 06:28 PM #782

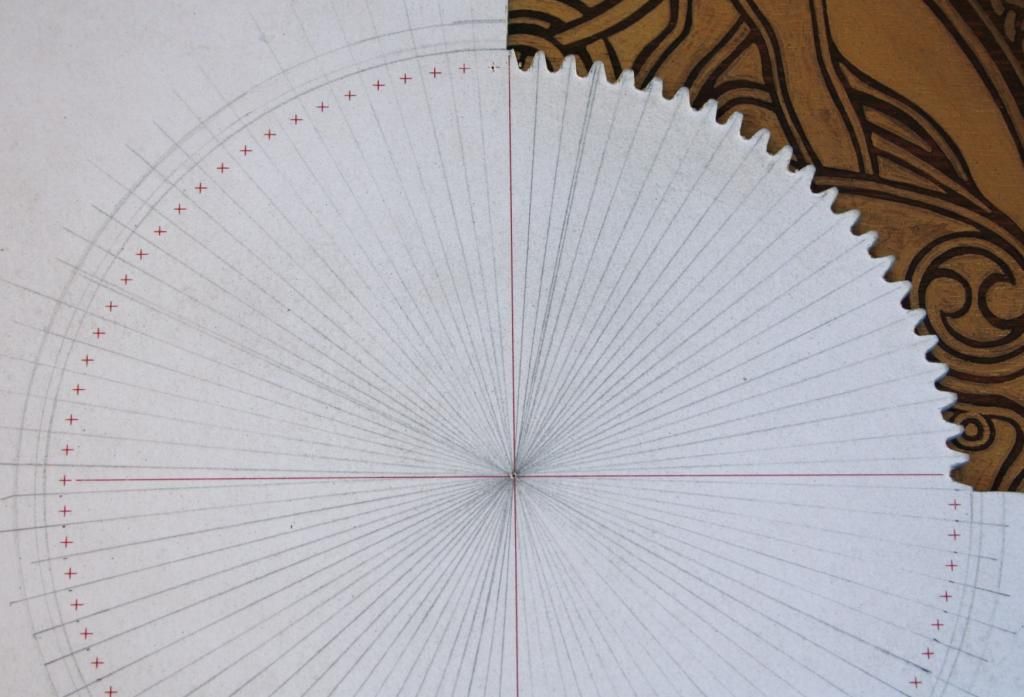

After a few days of kicking myself for not being able to workout how the heck to use those gear pattern generators.

I decided to go back to my low tech method and do it the old fashioned way.

I draw up a 180mm circle with 88 divisions on it and drilled some holes.

Then market in the teeth and started cutting on the bandsaw.

So far I've only cut out a 1/4 of it just to see if it was going to work.

The teeth themselves are only 5mm high which makes it a little fiddley.

But it seems to be working quite well.

I'll keep cutting away tomorrow and hope I don't make to many mistakes.

But it's not as if it needs to work so any mistakes should be able to be fixed with bodyfiller.

Cheers

Trev.

-

18th September 2014, 10:22 PM #783

So far it looks like a real one from here

. I hope you progress through the rest without any trouble.

. I hope you progress through the rest without any trouble.

-

19th September 2014, 05:56 AM #784

Thanks mate,

Using 3mm MDF to make the sprocket is working alright.

But the bandsaw maybe a little to much for the job.

I have a fairly fine blade on it but it is still tearing the edge of the MDF a little.

I think before I cut the rest of the teeth I'll run some super glue along the edge.

It gets into the MDF quite well and makes it a lot stronger cutting down no the tearing.

We'll see how it goes!

Cheers mate

Trev.

-

19th September 2014, 09:37 AM #785

GOLD MEMBER

GOLD MEMBER

- Join Date

- Apr 2013

- Location

- Torquay

- Posts

- 4,422

Trev,

Your gear looks great

Job well done !!!

Keith

-

19th September 2014, 11:29 AM #786

-

19th September 2014, 12:30 PM #787

-

19th September 2014, 05:19 PM #788

Here's as much as I've got done today.

The idea of running super glue around the edge of the MDF worked a treat.

I had none of the previous problems with the MDF tearing.

I drilled out the rest of the holes and cut the MDF down to size.

After drawing all of the lines and angles by hand I think next time I really need to learn how to use one of those gear generator's.

Then it was a matter of cutting all the teeth out.

After that I sat down with some 180 grade sandpaper and shaped them.

There was no major hiccup's along the way but it took a lot of time.

I'm not about to say it's the most perfectly cut sprocket but from a couple of feet away it looks alright.

The one thing I've noticed is that it sits a little flat on the spokes.

So I'll modify it at the back with some spacers to move it a little further away.

The other thing is the version of the sprocket I've been looking at is in two pieces.

So that it can be fitted without taking the wheel out.

I think I'll add that detail!

Hopefully if there's going on with it people wont look at the teeth to much

Cheers

Trev.

-

19th September 2014, 08:47 PM #789

You are just going to have to have a go at a wooden geared clock, Trev.

Chris

Chris

========================================

Life isn't always fair

....................but it's better than the alternative.

-

19th September 2014, 10:12 PM #790

Looks fantastic

-

20th September 2014, 05:18 AM #791

When I was younger (about this time yesterday).

I had it in my head to build a room full of wooden gears and levers.

Even a huge clock in the middle of it all with a giant governor on top of it.

When you opened the door at one end you'd pull a lever that set it all in motion.

About five minutes later at the other end of the room it would flick on a light switch.

I was going to call the hole thing "Progress"

I really am a Luddite

But after trying to make one little sprocket I'll leave the idea for another lifetime.

Cheers mate

Trev.

-

20th September 2014, 03:14 PM #792

I made up some spacers this morning to move the speedo drive away from the spokes.

Mounted on the wheel it looks about right.

The drum brake needs to fit in front of it.

So there'll be some juggling around to be done.

I'll add the detail of the speedo drive being in two halves after the drum has been made.

I also need to get the spacing right on the drive sprocket on the other side.

Still I'm getting closer to be able to strip it all down to be painted.

That's the part I'll really enjoy I've pretty much seen enough of the grey primer.

Cheers

Trev.

-

20th September 2014, 03:27 PM #793

Trev, this is an amazing piece you are unbelievably talented and I truly admire your works.

Cheers,

Frank.

In trying to learn a little about everything,

you become masters of nothing.

-

20th September 2014, 07:28 PM #794

-

20th September 2014, 11:28 PM #795

Im still speechless

Cant wait to see it totaly finishedThe person who never made a mistake never made anything

Cheers

Ray

Similar Threads

-

How straight does a straight edge need to be?

By Sir Stinkalot in forum WOODWORK - GENERALReplies: 20Last Post: 8th November 2013, 10:41 AM -

Aluminium straight edge - not so straight

By Dengue in forum WOODWORK - GENERALReplies: 28Last Post: 7th November 2010, 09:54 AM -

How straight is your straight edge?

By echnidna in forum HAND TOOLS - UNPOWEREDReplies: 17Last Post: 5th November 2005, 10:12 AM -

3m straight edge - or how straight can one get angle iron

By burn in forum WOODWORK - GENERALReplies: 10Last Post: 16th February 2004, 07:06 AM

Thanks:

Thanks:  Likes:

Likes:  Needs Pictures:

Needs Pictures:  Picture(s) thanks:

Picture(s) thanks: