Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 74

-

14th September 2017, 05:30 PM #1

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- Dandenong Ranges

- Posts

- 266

Coffee table - legs to rail attachment

Coffee table - legs to rail attachment

Hey all. I asked if tapering the legs of a little coffee table I'm making would reduce the strength and the answer got me really thinking about how to join the rails (aprons?) to the legs.

I don't have a lot of experience and what I do have is almost all with boxes. I got rather determined to get the boxes to come out well and it's been a nice change with the table so far to let that go and have fun. On the other hand I have enough of the same wood as the top is made from to make the rails and I would rather not stuff up completely and have to use different wood.

A simple version of a mortise and tenon is what I am looking for that still has reasonable strength.

Was thinking of having the tenons go through the legs but I got rid of the breadboard ends so I want the short and long rails at the same height so maybe not I could have tenons that have two shoulders instead of four - either the vertical or horizontal. Right now I am wondering if one shoulder on the outside and putting dowels through the leg going through the tenons as well might work?

I could have tenons that have two shoulders instead of four - either the vertical or horizontal. Right now I am wondering if one shoulder on the outside and putting dowels through the leg going through the tenons as well might work?

Easy-ist but strong-ish. No screws, dowels, biscuits etc. Just don't want to.

-

14th September 2017 05:30 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

14th September 2017, 05:54 PM #2

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2003

- Location

- Central Coast, NSW

- Posts

- 3,330

Rather hard to follow. Perhaps a diagram might help us understand what you are planning.

Cheers

ArronApologies for unnoticed autocomplete errors.

-

14th September 2017, 06:39 PM #3

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- Dandenong Ranges

- Posts

- 266

I tried drawing it. Unsuccessful. Found a picture and it has a name - according to this it's a barefaced tenon.

So I was thinking this might be easier for me. I could drill a hole or two through the whole leg including the tenon and glue in a dowel through the whole lot. My thought was to give a little more strength to the joint with the dowel.

-

14th September 2017, 06:40 PM #4

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- Dandenong Ranges

- Posts

- 266

And thanks for letting me know it wasn't clear. I wasn't sure

-

14th September 2017, 06:49 PM #5

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- Dandenong Ranges

- Posts

- 266

Sorry trying to work out why the picture didn't appear

-

14th September 2017, 06:53 PM #6

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- Dandenong Ranges

- Posts

- 266

-

14th September 2017, 06:56 PM #7

... and this too shall pass away ...

... and this too shall pass away ...

- Join Date

- May 2012

- Location

- Brisbane (Chermside)

- Age

- 71

- Posts

- 2,084

A good mortice and tenon joint will not need any additions such as dowels. If the fit is not spot on, use an epoxy glue to fill any voids.

-

14th September 2017, 08:30 PM #8

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- Dandenong Ranges

- Posts

- 266

I was thinking that the shoulders of the tenon must add to the strength. The vertical and horizontal shoulders would press on the leg with pressure and reduce the chance of splitting the tenon?

I really know very little - I had never even screwed something together until a year and half ago.

-

15th September 2017, 12:08 PM #9

... and this too shall pass away ...

... and this too shall pass away ...

- Join Date

- May 2012

- Location

- Brisbane (Chermside)

- Age

- 71

- Posts

- 2,084

Mnb,

We all start out knowing zip about woodworking. The only difference between you and craftsmen like Wongo and Ian (and a bunch of other craftsmen here) is a little education and experience.

In engineering terms a M&T joint can be complex as one works out turning moments and tensile, shear and compression forces. However, the short answer is that when gluing long grain to long grain nearly all of the strength comes from the glue area in long grain.

So, for a M&T joint we assess strength based on the area of long grain on the cheeks of the tenon. The edges don't count. That's why the Domino folk are happy to have us cut an oversize length for the floating tenons. Nearly all the strength comes form the glue area on the sides of the tenons, providing we have a good fit between the cheeks of the tenon and the sides of the mortice. If these are not a good "tap in" fit, epoxy should be used to fill any gaps.

When I started woodworking I made a few joints of different types and tested them to destruction. A decent M&T joint will hold, and the timber will split along the grain. If the joint is stronger than the timber, and it should be, any attempt to add extra strength is, in most cases, wasted. The timber will split when it will split, even if you double the strength of the joint itself.

Even biscuit joints can do a decent job, especially if we use 2 or 3 biscuits to make a joint, but M&T joints (or floating tenons) are stronger and they make assembly a breeze compared to biscuits. Once you own a Domino you will wonder how you got by without one, but they are not cheap. Nevertheless, all the coffee tables in my house were made 15 years ago with biscuits, and they are all in great condition.

I have made few M&T joints (mostly for frame and panel construction or for glass panels in a timber frame). These days I use a Domino and floating tenons, but my tests with double or triple biscuits suggest that there is not much wrong with good biscuit joints. For the budget conscious biscuit cutters are an economic option, and the biscuits themselves are inexpensive. The pic is a display cabinet I made 15 years ago shortly after coming to woodworking. Because I knew no better, the joinery is all single biscuits, including the glass doors. 15 years and two moves later, it is still like new.

-

15th September 2017, 12:24 PM #10

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- Dandenong Ranges

- Posts

- 266

I apologise. Not used to interacting online. I should have taken the time to think about what I was trying to ask. Thanks John. That is a good explanation and exactly what I was wondering regarding m&t.

Could someone explain the various forces on a table and which direction they act. I love understanding the reasons behind things and it will probably help in the future.

I really want to do a m&t. Even if I don't use it much in the future it feels like something I should be able to do. Maybe I am getting caught up in purity thing. Though I have found that attempting something above my skill level, but not impossible for it, has taught me a lot more than the ability to do that specific thing. In other words I will learn from the attempt.

-

15th September 2017, 01:02 PM #11

... and this too shall pass away ...

... and this too shall pass away ...

- Join Date

- May 2012

- Location

- Brisbane (Chermside)

- Age

- 71

- Posts

- 2,084

No need for an apology. We are here to help each other.

Wood is stronger in compression than it is is tension. Compressive forces try to compress or to squeeze the member. Tensile forces want to pull the wood apart. In fact, wood is very strong in compression, which is why cabriole legs are plenty strong enough. So long as you can draw a vertical line through the leg and remain in wood, the leg is likely to be fine.

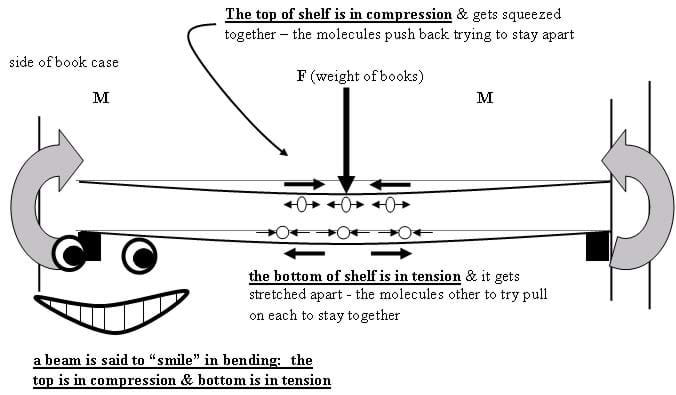

Imagine you have a coffee table without a top, and you stand on the aprons. The weight is transferred to the legs. Because they are holding in compression, they will be fine. However, where the aprons attach to the legs (assume a M&T joint) the aprons suffer two sets of forces we need to know about. First there is the tendency of the apron to bend, introducing what is called a turning moment.

When we stand on the aprons (and they bend a tad) the top of the apron is in compression (strong) and the bottom is in tension (not so strong) which is why such timbers will fail from the bottom up. To prove that, put a piece of wood across your knee and pull on the ends until it fails. It will fail in tension. Many years ago I came home late to find that my wife and her mates had been on the wine. One of them was dancing on one of my coffee tables. It held just fine. If the rails are a decent size, they will not snap in the middle.

The stress we need to be aware of is that around the joint. When you stand on the apron, the tenon wants to "shear" off the apron and/or the tenon will try to turn in the mortice. Wood is reasonably strong in shear, so with a decent M&T joint that should not be an issue. The joint will likely hold for a decent M&T joint because the joint is stronger than the timber is along the grain. If you were elephantine is size, the apron will bend and the most likely form of failure is for the leg to split along the grain right at the edge of the tenon in the leg (assuming a good M&T joint).

Long answer short ... with well made joints wood will generally hold well in compression and in shear. Failure tends to be in bending (in tension, where the forces try to pull the wood apart) so either the apron will crack at the bottom and then fail, or you will split the leg. This is a bit simplistic, but is good enough for a start, I hope.

In summary, a well made M&T joint tends to be stronger than the wood. If the wood will hold, so will a well made joint. The same can be said of table tops. Because you are joining long grain to long grain, a well made joint is stronger than the timber, so if we use dowels, biscuits, splines or tenons, it is usually for location rather than for strength.

I read these words a long time ago, but have a tendency to test matters for myself. I jointed two boards together and tried to break the joint a couple of days later. The timber split; the joint held. Then I made M&T and biscuit joints with a rail and a stile. The rail was put in a vice and I pulled on the stile until it split along the edge of the biscuits or of the tenon. The theory works. A well made joint is generally stronger than the wood.

If you want to make a M&T joint, go for it. Usually, the tenon is (at least) one third as thick as the wood member, but in the example you posted (barefaced M&T) the tenon is likely to be one half the thickness of the member, so it will be stronger in shear.

-

15th September 2017, 01:15 PM #12

... and this too shall pass away ...

... and this too shall pass away ...

- Join Date

- May 2012

- Location

- Brisbane (Chermside)

- Age

- 71

- Posts

- 2,084

Does this help? Do a Google search for "beam, compression, tension, shear" for more info.

The shear forces act right where the apron meets the leg.

Another example ...

-

15th September 2017, 01:24 PM #13

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2003

- Location

- Central Coast, NSW

- Posts

- 3,330

Just adding to Johns excellent explanation on m&t joints, there are three reasons I can think of to have a shoulder on a tenon.

1 for aesthetics. Most of us who still chop mortises by hand will tend to leave the top edge of the mortise a bit messy - especially when getting lazy and levering chopped up timber out. The shoulder hides all this.

2 it can be a natural consequence of reducing the thickness of the workpiece to give a reliable tenon. There are lots of tests of joints on the web, and in the main they show that if a joint is going to fail it's going to split around the mortise - the tenon or biscuit or domino is rarely at risk. Getting the size of the mortise re the thickness of the leg right is the important bit.

3 for alignment. They help a great deal during a complicated glueup.

Strength is not one of the advantages, in fact I've always wondered whether they sometimes reduce strength by providing a point of leverage beyond the extent of the mortise.

So yep, the barefaced tenon you show is good. Shoulders at the front to hide the join and barefaced at the rear because no need to reduce strength. Plus time saving.

ArronApologies for unnoticed autocomplete errors.

-

15th September 2017, 04:28 PM #14

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- Dandenong Ranges

- Posts

- 266

Thanks

Thanks

Thank you both for those replies.

John, that was a fantastic explanation. I so appreciate you taking the time to write it.

My daughter is distracting me at the moment - will post later.

-

15th September 2017, 06:51 PM #15

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- Dandenong Ranges

- Posts

- 266

Arron, I think I have discovered another reason for having shoulders. Vertically anyway. I started the mortises this afternoon after reading your posts and realised that the barefaced tenon means either the rails need to be below the top of the legs or the mortises open to the top of the legs. So a shoulder at the top means the top of the rails can be flush with the top of the legs AND the mortises can have a top wall. (Not sure of the correct terminology.)

Similar Threads

-

Coffee table legs

By Mnb in forum FURNITURE, JOINERY, CABINETMAKING - formerly BIG STUFFReplies: 10Last Post: 11th September 2017, 08:37 PM -

Coffee table legs

By bassmansimon in forum WOODWORK - GENERALReplies: 7Last Post: 8th April 2012, 07:15 AM -

Turned Coffee table legs.

By Robomanic in forum WOODTURNING - GENERALReplies: 0Last Post: 22nd February 2009, 04:28 PM -

Coffee table legs question

By basser425 in forum FURNITURE, JOINERY, CABINETMAKING - formerly BIG STUFFReplies: 5Last Post: 1st January 2009, 03:51 PM -

Ideas for coffee table legs

By Afro Boy in forum WOODWORK - GENERALReplies: 12Last Post: 29th December 2007, 01:02 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote