Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 6 of 6

Thread: The journey of a new project.

-

14th October 2013, 03:50 AM #1

The journey of a new project.

The journey of a new project.

I am interested to know how others plan their projects, and about the interesting discoveries they make along the way.

For the past month or 6 weeks, I have been accumulating information about Wegner's "The Chair".

I plan on building this ...

... but with this seat ...

Usually I create a basic plan consisting of a few dimensions, with the image and details locked inside my head, decide on the build sequence, and then just start working.

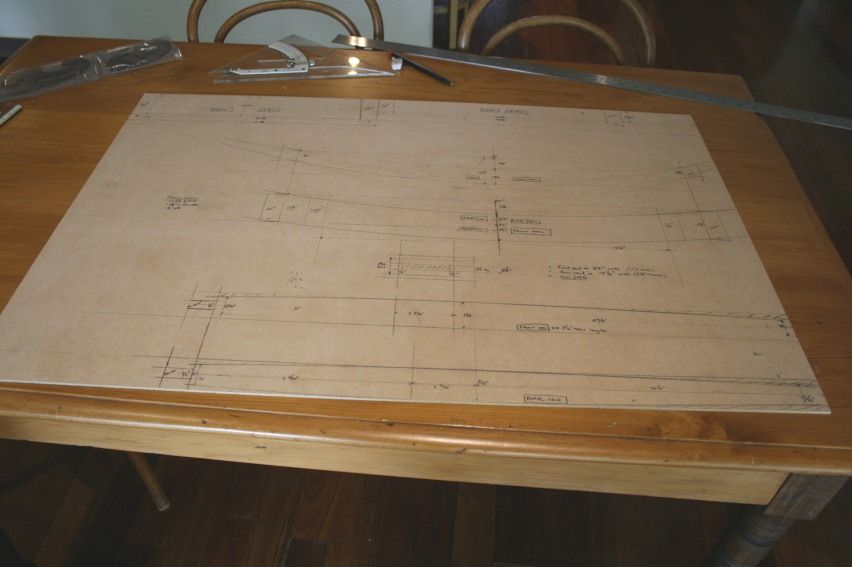

This time it is different. For a start I am copying a famous chair and the details are important. Never mind that I do not have one at hand to measure and work from, but I have not actually seen The Chair in the flesh. I've been fortunate to obtain several important measurements, which have enabled me to draw up full size plans ...

Measurements have become important as the drawings unfold a picture of complex curves built from solid wood, and the realisation that bigger chunks of timber are necessary than I had imagined at the start. I needed 6" x 6" posts.

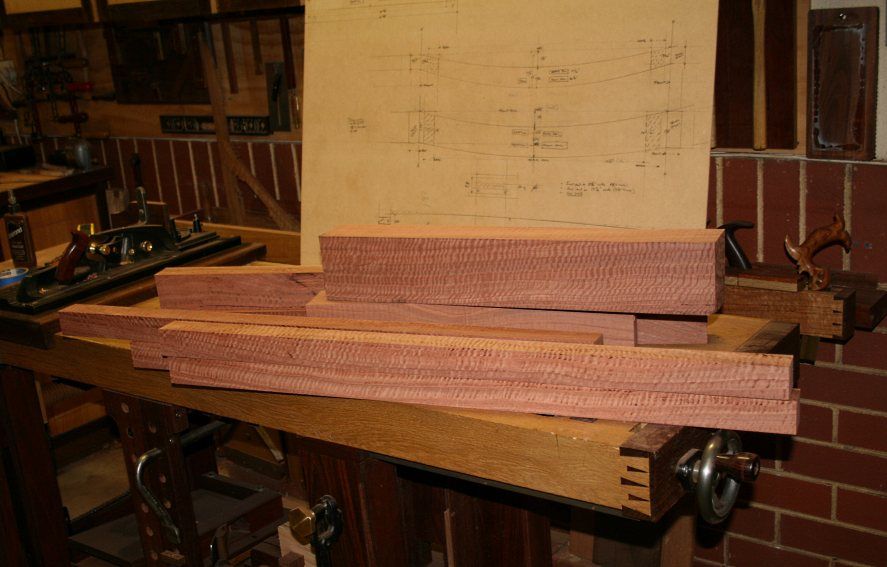

I went looking for wood ... and met Derek The Timber Bloke. Yes, another Derek. Derek (the other one) flies helicopters in his day job and spends his spare time and weekends salvaging urban trees. He stores, resaws, and sells some very exotic West Australian timbers. I called Derek, and he said that all he had was 13 feet (4m) of fiddleback (curly) Jarrah in this size that was from the same tree, dry and ready to go.

I must admit that I had mixed feelings. I had recently completed a kist in curly Marri, and it was a real bear to work - not just because the wood was hard, but because there is the added complexity of matching the direction of the curl as well as the colour of the wood and the grain. I really wanted to get on with the build, and so I decided to have a look at it. Anyway, I had not visited Derek before, and this was a good excuse. How many of us need an excuse to look over a new wood supplier. And just 30 minutes from my home.

The storage was impressive. This was just one of two warehouses ...

Derek The Timber Bloke (no, not me) ...

I bought the curly Jarrah. Derek gave it to me quite cheaply ($150) as there was a good deal of checking and it would be necessary to saw around this. I guess that is somewhat expected with 6" x 6". I loaded it into my wife's Golf, feeling shocked at the incredible weight of each section, and wondering how I was going to manage this in my shop.

About two weeks have passed while I plotted and planned. Today I began sawing the timber. This represents the 4 legs and the 4 rails.

My plan is to build the lower section of the chair first. The chair back and arms will be easier to size and position this way. Onward to the lathe ...

Any thoughts or stories of your own?

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

14th October 2013 03:50 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

14th October 2013, 10:39 AM #2

... and this too shall pass away ...

... and this too shall pass away ...

- Join Date

- May 2012

- Location

- Brisbane (Chermside)

- Age

- 71

- Posts

- 2,084

Very interesting project. I've pulled up a chair, filled my coffee cup and await the next installation.

I guess a lot of us are like you. usually, a rough sketch to start with and then figure the rest out as we go ... except when we are venturing into new territory, when more detailed planning is required.

-

16th October 2013, 09:12 PM #3

Here is a cross post from WoodCentral that some will find interesting:

What I like about the work of Wegner and Maloof is their use of sweeping lines. However there is a flow in The Chair and the Maloof rockers that does not work well in the Maloof chair. It just seems a little busy to me. I had been considering building one for a few years, and even purchased plans.

I envisage building The Chair in a way similar to the methods used by Maloof. Some of it is best done with power tools, such as a router for the mortices and a bandsaw for the rough shaping. Then it will be spokeshaves and scrapers.

The measurements and templates I am building will help get close. And then it is by eye.

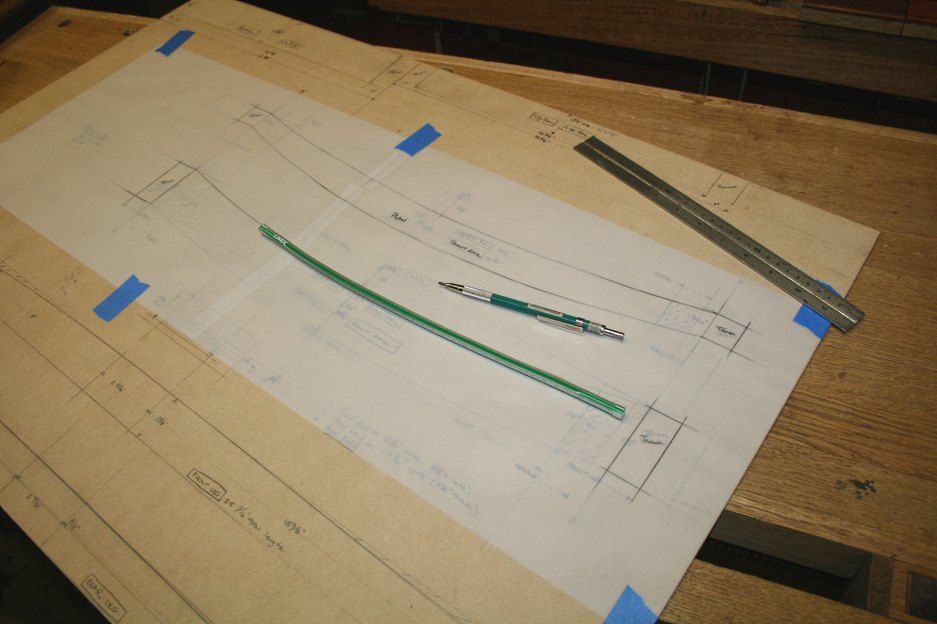

Tracing the drawings onto templates ...

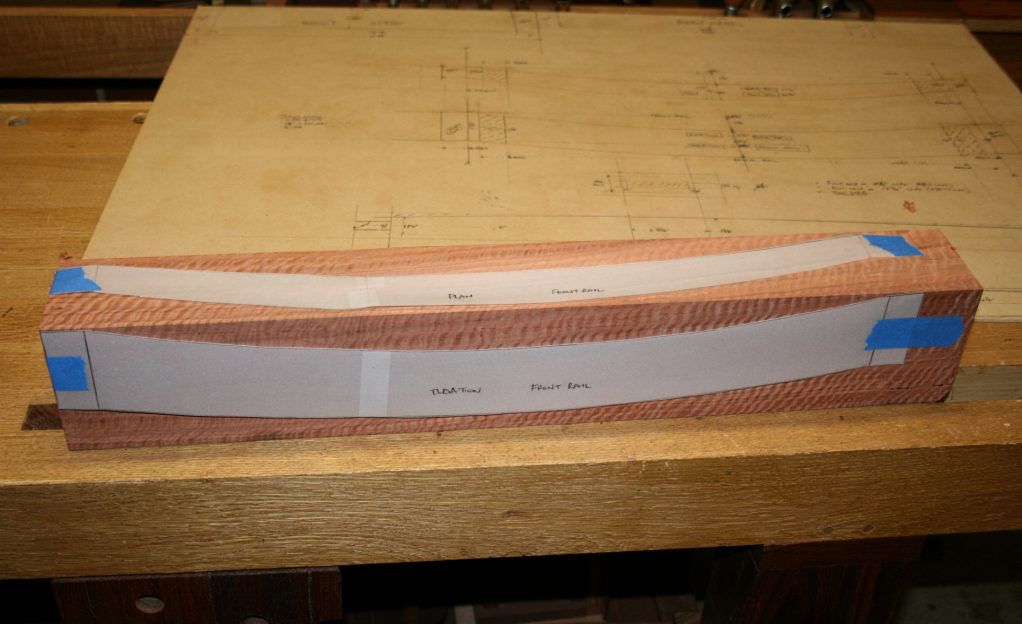

Just to show the templates. Which would you saw first, the top or the bottom?

I was advised ...

Maloof's bandsaw carving: Sam Maloof: "And that's the arm" - YouTubeCut and fit your joinery first, while you still have reference surfaces.

Cut the concave faces first, because your offcuts will come off in one piece, instead of several. Then tape them back onto your stock (using 3M blue painter's tape, but you knew that) to provide support and reference faces for subsequent cuts, and also to preserve the marks you made from the pattern.

Using the bandsaw the way Sam Maloof did is something I just shake my head at. My Hammer 4400 scares me at times as it is so powerful that an unsupported board can be (has been!) ripped out of my hands. A thinner blade than I usually use - 1/4" rather than 1/2" - may help. Sam's looks like 1/4".

The issue of joinery first or later is one that I have been thinking about for some time.

The given for most joinery is to work/mark from a reference side. The joinery here is (1) mortices in the round legs and arms, (2) tenons on the stretches, and (3) finger joints on the chair back/arms.

The mortices on the legs will be cut after the legs are turned. I could do this before (have done this in the past), but I am concerned the wood will chip out too much even with the mortice plugged with a filler piece. Further, there are intersecting mortices, and these are not at right angles. In fact I will only be sure of the second angle when there are parts to fit together.

The reason for a router for the mortices is that the tenons are haunched, that is, the mortices will have two depths each. That is difficult to chop accurately. Of course I could use a different joint, but I did want to explore what Wegner designed.

Here is the mortice and tenon joinery used on The Chair (stills taken from the video):

Tenon ...

Mortice ...

Tenon into mortice ...

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

16th October 2013, 10:51 PM #4

A bit of luck

A bit of luck

Today I won an auction for an original Wegner The Chair. These were made under license in Australia for a short while in the 1960's. The price was low, so I am feeling quite pleased. This is a solid seat, in Tasmanian Blackwood and Teak.

I am going to put any sawing on hold until it arrives so I can check the measurements I have. It is on the other side of Oz, and will take a few weeks to get here (I have to arrange shipping).

Now I will have a proper model to compare to. That should make a very big difference. Importantly, I shall have the seating to explore first hand.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

16th October 2013, 11:07 PM #5

I will be watching this work in progress. Could I ask why this chair? Does it have to be exact copy?

-

16th October 2013, 11:15 PM #6

Hi Christos

It doesn't have to be an exact copy - I doubt anyone could do that - but I would like to get close. Partly it is the challenge and partly it is homage to the designer.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

the secret project ... near the end of the journey

By fletty in forum WOODWORK - GENERALReplies: 79Last Post: 20th October 2010, 10:05 PM -

One Man's Jig Journey

By Carry Pine in forum BOX MAKINGReplies: 2Last Post: 12th August 2010, 10:35 AM -

The Journey Of Man

By Barry Hicks in forum WOODIES JOKESReplies: 2Last Post: 24th April 2008, 04:50 PM -

I'm going on a journey, man

By journeyman Mick in forum MOTOR HOMES, CARAVANS & CAMPINGReplies: 34Last Post: 3rd July 2007, 11:54 PM -

The journey

By ozwinner in forum WOODWORK - GENERALReplies: 7Last Post: 12th July 2004, 05:23 PM

Likes:

Likes:

Reply With Quote

Reply With Quote