Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 4 of 4

Thread: A Chip Guard for the 260

-

3rd November 2010, 12:14 PM #1

Cba

Cba

- Join Date

- Aug 2007

- Location

- Melbourne

- Age

- 68

- Posts

- 1,417

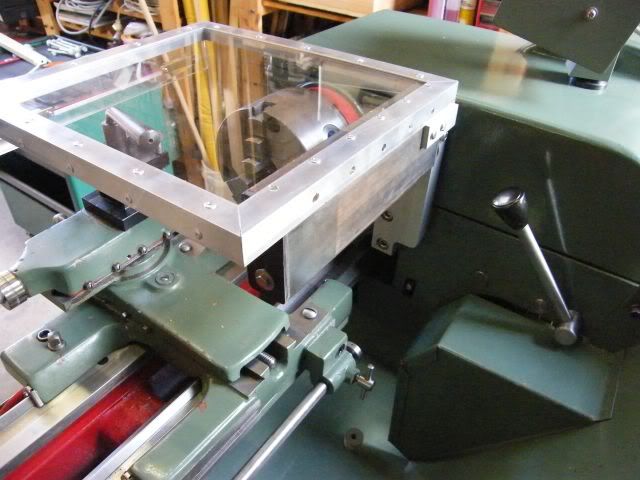

A Chip Guard for the 260

A Chip Guard for the 260

F.W. Hercus have an "interlocking chip guard" for the 260 on their website. They want an outrageous AU$ 499.00 + GST for it. 260 Metal Lathe - Interlock Chip Guard - F W Hercus Pty. Ltd

I had a homemade chip guard on my older lathe for 20 years. It served me well and I still like to use it whenever possible. It protects from flying chips and coolant when working close to the chuck. And it protects my eyes without the need to swap my ordinary glasses for protective plastic glasses which I hate...

Anyway, I decided to make my own chip guard for the Hercus 260, slightly improving on my old one. No, no interlocking switch, I want to be able to use the lathe with the guard open or closed. I am the only person using my lathes, so there is no ohs issues for me.

So this is what I came up with

(Yes the lathe is still on wheels, it will be a while until I convert my garage. The smaller lathe/mill lives indoors in a spare bedroom)

The little allen screw on top of the mounting bracking adjust how deep the lid can close

Plenty of room for the 4-jaw chuck too.

Hope you like, Chris

PS: it turns out to be VERY rigid - I can put a sixpack on top and it will barely sag 2mm. Probably overkill.... could be made simpler next time

-

3rd November 2010 12:14 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

3rd November 2010, 12:44 PM #2

Cba

Cba

- Join Date

- Aug 2007

- Location

- Melbourne

- Age

- 68

- Posts

- 1,417

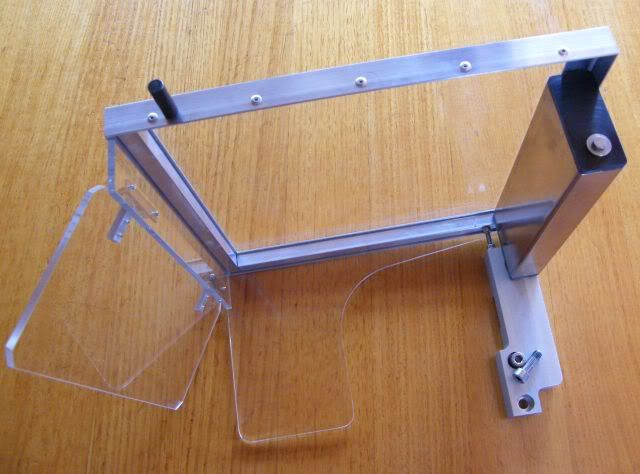

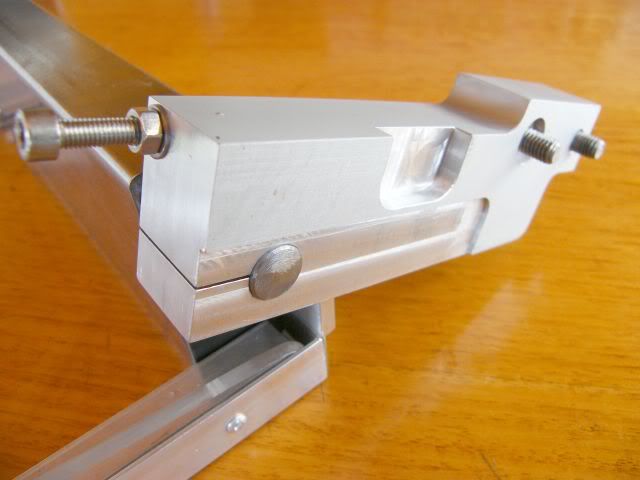

Here some more pics about how it is made. Essentially, I had a look in my scrap bin and designed something around materials I already had at hand. The clear window is 4.5mm acrylic sheet that I long ago bought as large offcuts on eBay. Most of it I used for chip guards on my mill. The rectangular ally profile is a reclaimed scrap, the framing profiles and the kitchen door snap locks are from the big green warehouse. The black delrin I bought from offcuts galore eBay a while ago - whilst machining I found out it is too soft to be delrin, it is something cheaper, but it works.

The holes I bored in the lathe, it is for the 1/2" ground steel shaft (salvaged from an old laser printer).

It's all riveted together with 3.3mm Ally rivets

The 1/2" thick ally bracket is actually cut from a scrap part. The screws are M8, so I has to drill and tap M8 where it attaches to the Hercus.

The golden part is a kitchen door snap lock. I tossed away the central part, and replaced it by a hinge piece that I milled out of some scrap. By tightening the two large slotted screws I can adjust for enough friction to hold the lid in any position. It is exactly the same system I used 20 years ago on my old chip guard, so I am confident it will last at least that long.

Same from inside. I threaded M3 directly into the perspex

From the side

The 1/2" steel shaft is clamped into the slitted bracket. When using the faceplate, I simly loosen the M6 clamp screw from behind with an allen key, and remove the chip guard from the bracket which can remain attached to the lathe. Quick and easy.

The bar at the bottom right limits how for the whole canopy can be swung back.

-

3rd November 2010, 12:54 PM #3

Product designer retired

Product designer retired

- Join Date

- Nov 2006

- Location

- Heidelberg, Victoria

- Age

- 79

- Posts

- 2,251

Well done Chris,

That's a very professional looking guard, seems a bit of a shame to cover up some of that magnificent 260, still eyesight comes first. The hinge arrangement is cool, using cabinet catches is very clever.

Reckon I'd like to see some green paint applied to the aluminium frame, to help make it blend in. Just a thought.

Ken

-

3rd November 2010, 02:54 PM #4

Mechanical Butcher

Mechanical Butcher

- Join Date

- Oct 2004

- Location

- Southern Highlands NSW

- Posts

- 920

The only good thing about failing eyesight - I've always got protective specs on!

That's a nice job, isn't it? I might have put a metal plate on the other side of the plastic for the brass hinges, to strengthen and maybe avoid future cracking.

Jordan

Similar Threads

-

New chip amplifier

By hybridfiat in forum HI FI EQUIPMENTReplies: 21Last Post: 4th February 2010, 01:16 PM -

Chip on or patch up?

By Reno RSS Feed in forum BRICKWORK, CONCRETING, PAVING, RENDERING, etcReplies: 0Last Post: 24th July 2009, 08:10 PM -

Dry as a chip

By Allan at Wallan in forum WOODIES JOKESReplies: 2Last Post: 9th January 2008, 11:18 PM -

Anyone want to chip in?

By Grunt in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 14Last Post: 18th February 2007, 10:42 AM -

if we all chip in...

By Slow6 in forum HAND TOOLS - POWEREDReplies: 4Last Post: 30th November 2006, 07:47 PM