Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Results 1 to 7 of 7

-

19th March 2017, 05:46 PM #1

Member

Member

- Join Date

- Aug 2015

- Location

- Victoria - Ferntree Gully

- Posts

- 53

My dust extraction journey begins here.

My dust extraction journey begins here.

I thought I would share my journey in dust extraction.

I love doing woodwork, however woodworking does not agree with my health. I'm an asthmatic and cant handle the dust created by my machines.

Here lies a dilemma. I already have some safety measures in place to allow me to do this, but they just are not good enough to allow me to work without some suffering.

So I have decided to do something about it and am heading down the path of making my dust extraction work.

So what do I have at the moment?

A 20+ year old generic 2hp Dusty

IMG_0573.jpgIMG_0572.jpgIMG_0571.jpg

It does however have a 6 inch outlet from the impeller housing which is a good start!

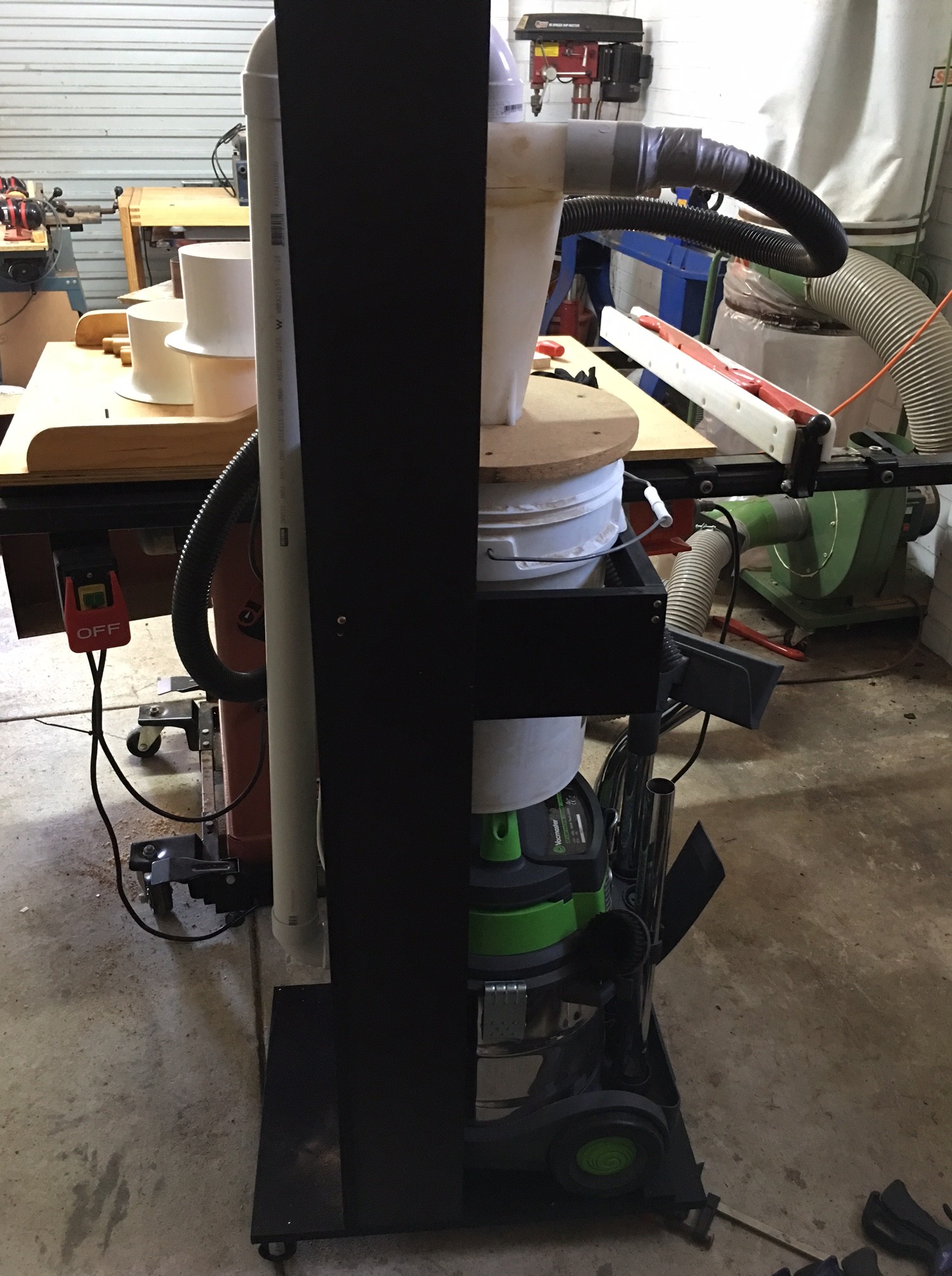

I have also made up a dust extraction cart with a shop vac and a dust deputy cyclone for use with my orbital sander.

IMG_0578.jpgIMG_0577.jpgIMG_0576.jpgIMG_0575.jpg

I have a few woodworking machines that need better DE;

Table Saw

Bandsaw

Jointer

Drum Sander

Belt Sander

Lathe

So I thought the best place to start would be with the DE guru himself, so BobL came over for a look at what I have to see what could be done!

A big thankyou to BobL for his time on Friday, it was great to meet you and I had a very enjoyable conversation regarding the ways that I could improve my DE and hence my health. We are very lucky to have such a knowledgeable person who is willing to offer their advice and expertise to us.

Anyway this is my thread to show my progress of my dust extraction setup, which might just take a little while to complete with all of my other commitments, however I thought it would be good to share my experiences on a path to better DE.

First job is to modify Dusty (my kids nickname for the SANFU 2hp DE)

I have the BMH's for the impeller inlet (Thanks Bob!)

IMG_0574.jpg

Next job is to work out how to relocate the inlet to the dust separator to the other side to allow the DE inlet to be on top, and the flows to be in the right direction.... At the moment I am thinking that I will need to cut off the seperator inlet and weld it onto the other side, and then block off the hole that is created. - If anyone has some better ideas Im open to suggestions.

Once all of the DE is sorted I will need to fabricate some sort of enclosure either inside or outside the workshop.

-

19th March 2017 05:46 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

19th March 2017, 06:50 PM #2

Woodworking mechanic

Woodworking mechanic

- Join Date

- Jan 2014

- Location

- Sydney Upper North Shore

- Posts

- 4,469

I've just about completed a total upgrade of my 2HP unit (really 1.5HP if you go by my measurements).

Your lucky having a 6" inlet to the separator. I'm upgrading mine from 5" to 6" at the moment. Good move on the 6" inlet - BobL's BM inlet will work a treat.

I take it you are removing the pump and motor from the base, turning the impellor and motor on the side and raising it up to separator height and that's why do you want to move the inlet from the LH side to the RH side of the separator - if I'm reading you right?

Can the inlet face down? Others on this site have done that and some machines come that way.

I don't know what the gauge of your separator metal is, but mine is like tissue paper so welding is going to be tricky. I'll let you know how it goes.

so welding is going to be tricky. I'll let you know how it goes.

Good luck and keep us posted.

-

20th March 2017, 10:39 PM #3

Member

Member

- Join Date

- Aug 2015

- Location

- Victoria - Ferntree Gully

- Posts

- 53

Hi Lappa

Yes you are correct, the plan is to remove the motor from the base and to turn the impellor housing onto its side.

I might have to rethink the design if welding is not an option. Perhaps I could leave the existing port where it is and close off that hole, then cut a new inlet into the seperator, perhaps using a piece of 6" PVC with a radius cut into it the same diameter as the seperator housing. Then make an mdf block, again with the same radius as the seperator and with a 6" hole in it.

This would give me something to attach to the seperator, and something to attach to the 6" PVC. It would also allow me to return it back to standard if I ever wanted too.

http://imageshack.com/a/img923/5696/dngLxY.jpg

http://imageshack.com/a/img921/8341/9FXOTl.jpg

http://imageshack.com/a/img921/8412/akvwwQ.jpg

http://imageshack.com/a/img924/4646/pEIiCj.jpg

http://imageshack.com/a/img921/1184/KmcyeN.jpg

http://imageshack.com/a/img922/892/JsAigc.jpg

http://imageshack.com/a/img923/6128/40SQ32.jpg

http://imageshack.com/a/img922/2784/uLtaDl.jpg

-

20th March 2017, 11:13 PM #4

Member

Member

- Join Date

- Aug 2015

- Location

- Victoria - Ferntree Gully

- Posts

- 53

-

21st March 2017, 11:01 AM #5

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,790

I thought you were going to connect the impeller and filter housing with just a very short length (cm) of straight flex?

-

21st March 2017, 05:52 PM #6

Woodworking mechanic

Woodworking mechanic

- Join Date

- Jan 2014

- Location

- Sydney Upper North Shore

- Posts

- 4,469

I had mine welded this week. Picked it up today. Thin but able to be welded. See Generic 2hp thread near the end

-

23rd March 2017, 10:40 PM #7

Member

Member

- Join Date

- Aug 2015

- Location

- Victoria - Ferntree Gully

- Posts

- 53

Not sure yet Bob, going to get all of the parts together and then decide if I go up or down with the inlet pipe.

Similar Threads

-

Not quite dust extraction......rathermore hot air extraction....

By FenceFurniture in forum DUST EXTRACTIONReplies: 23Last Post: 13th May 2014, 10:40 AM -

Dust extraction

By hardwoodjoint in forum ROUTING FORUMReplies: 7Last Post: 23rd August 2009, 03:27 PM -

ROS dust extraction

By TK1 in forum DUST EXTRACTIONReplies: 2Last Post: 2nd May 2009, 11:17 AM -

TS dust extraction

By greenie512 in forum DUST EXTRACTIONReplies: 9Last Post: 24th September 2006, 08:43 PM -

PVC for Dust Extraction

By sandman in forum DUST EXTRACTIONReplies: 3Last Post: 20th February 2004, 01:51 PM

Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote