Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 31 to 45 of 124

Thread: Show off your workbench

-

14th April 2007, 10:43 PM #31

What can I say?

.... I am sure it is there ... somewhere ... it was here yesterday!

... there is it ....

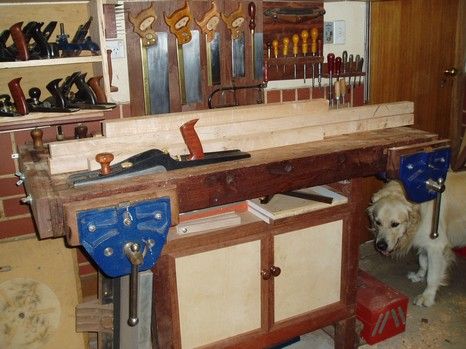

more functional than pretty. It began life about 12 years ago (when we moved into the current house) as a very basic top and legs. Mostly Karri salvage roof trusses. As I increasingly became involvedwith handwork it began to evolve - I never could justify the time to build another bench with so many household jobs to do (but the time is getting close when I will build the "dream bench"). Sometimes is pays to wait and understand how one prefers to work.

So there are "clever" add-ons, such as ...

an adjustable planing stop

a dovetail vise

Why two face vises? Because I can clamp large boards between them when jointing with handplanes. And, being right-handed, I actually prefer to clamp large boards on the right when sawing.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

14th April 2007 10:43 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

14th April 2007, 11:01 PM #32

Underused, you have a beautiful workbench.

and whatever you are working on is beautiful too.

Visit my website at www.myFineWoodWork.com

and whatever you are working on is beautiful too.

Visit my website at www.myFineWoodWork.com

-

14th April 2007, 11:39 PM #33

Skew, thou shalt not covet thy fellow member's bench

The beatings will continue until morale improves.

-

15th April 2007, 12:29 PM #34

Like many others my workshop doesn't allow me to put the bench in the middle ... but I do dream of being able to one day!

In case that dream ever comes true, I made the last slat on the bench top loose so that it can be slid up to stop tools from rolling to oblivion down the back or dropped down level with the bench height.

One day ......

Fletty

-

15th April 2007, 09:08 PM #35

You can see my 'first' bench here: https://www.woodworkforums.com/showth...618#post464618 which is designed to get me through the next few years until I build the real thing. I'm firmly with the recycled timber gang - this one's made from a friend's deck, the rest is feeding termites at the bottom of the garden as an on-ground deck. The photo is the day I put it in place - it now looks more like Derek's only with fewer quality tools! I'll post more pics when I've sorted out the vices.

Derek, I notice you've got a hand powered grinder - what do you use it for? The one I have has a smaller gear box, but it's the only thing I have to sharpen with. Oh, and can you explain how you fit your vices flush with the front of the bench? Thanks!

-

15th April 2007, 11:35 PM #36

There are some great benches posted here, envious of more than one!

I have to post photos of two benches, because I work equally in metal and wood, maybe use the metalwork bench more. The frames are both made from recycled material, mostly cypress, with a bit of hardwood and ply etc. Some through-tenons, all bolted together. Above each is a flouro, sliding along a swinging arm so I can throw light exactly where I need.

The metalwork bench is higher, and consists of 2 'towers' at each end with a gap in the middle, into which rolls my mechanic's toolbox. This allows me to move it to where I'm working, but also clears a space for sitting on a stool at the bench. There is a ply front on the steel frame, with a handle-cum-rag rack out front, and it locks into place when home. Cheap pivoting vice, would love to replace it with an offset one.

The woodwork bench is pretty basic, and has copped a real caning. I have just installed a homemade Wonderdog setup, but have only drilled holes where I needed them. Before that I just nailed cleats for wedges onto the bench when planing, working aginst a large drop-down stop at the far end of the bench. The vice is a quick release Chinese version, with a slip-in pivoting jaw I made. I'm planning a new bench, which will be trad European...even have some timber set aside (very large pine, 7"x 5"). That ugly metal sheeting in front is an unused door, and will one day be replaced with a wall and window.

Thanks for looking!

Last edited by Andy Mac; 15th April 2007 at 11:37 PM. Reason: forgot the photos!

Andy Mac

Change is inevitable, growth is optional.

-

16th April 2007, 12:55 AM #37

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,794

Yuv'all seen my main bench before before but just in case, plus a couple of additions.

Attached Photos show.

1) New front vice handle

2) Small tools/machine assembly/repair bench, underneath used to store power tools, drawers store all manner of bits and pieces.

3) A sort of metal work bench, frame welded up 27 years ago from a bed frame. Underneath you can see my sharpening stone tray - dripping onto a nice bit of sheoak - damn!!! Never mind have plenty more of that now.

Cheers

-

17th April 2007, 05:04 AM #38

Mick,

I purchased the Gramercy Holdfasts directly from Tools For Working Wood in the USA. I included them in an order with some other stuff in an effort to spread the cost of shipping over a few items. I've since found out you can buy them in Australia from Micheal Connor Woodwork.

I haven't had the holdfasts for long so I haven't used them a lot. So far though, they have worked fine. They lock down nice and firm with a simple whack from a mallet and they hold on tight. I'm very happy with them.Regards,

Ian.

A larger version of my avatar picture can be found here. It is a scan of the front cover of the May 1960 issue of Woodworker magazine.

-

17th April 2007, 11:14 AM #39

GOLD MEMBER

GOLD MEMBER

- Join Date

- Aug 2005

- Location

- Queensland

- Posts

- 2,947

My work benches aren't anywhere near as fancy as some but I could easily compete in the messy department - most horizontal surfaces have a magnetic attraction for all manner of bits and pieces.

I mainly use and old steel framed ping pong table [cut and shut to ply sheet size] on which I have attached a sheet of 19mm form ply and a support and storage shelf underneath - I also have 360 degree access.

As an "extra" table I use my trailer with a jockey wheel and brace at the tailgate end - inside is a removeable support frame which supports a top deck which is located with cleats. This allows me to move 360 degrees around the job or move the entire job from one place to another by moving the trailer - I have even on rare occasions worked by standing on the deck.

Regards,

Bob

-

17th April 2007, 10:23 PM #40

Member

Member

- Join Date

- Oct 2004

- Location

- Posts

- 84

There's some nice set ups here. Very sexy.

Mine's a little more basic.

First bench is made of spotted gum and bluegum, with shipwrights dovetails. This is my favourite bench, although it's very heavy, can be moved out from the wall to alow access around perimeter. 7ft x 3 ft and perfect height.

Second bench was slapped together in 2 seconds, just made from scrap pine, comes apart, one side has radial arm saw. 16ft x 3ft

Workshop is long and skinny so can't fit too much in @ just 65ft x 12ft. Still trying to work out how to fit my panel saw in, with a footprint of 22ft x 12ft

-

17th April 2007, 10:34 PM #41

Member

Member

- Join Date

- Oct 2004

- Location

- Posts

- 84

View of rest of the workshop.

Photos could be bit better.

-

18th April 2007, 07:22 AM #42

Here is my current workbench.

It uses salvaged 32mm chipboard covered with white laminex, where the base uses salvaged hardwood that is seriously hard...

Workbench is about 8 foot long and as the workshop is only 18 foot wide it tends to dominate the shed a bit.....

Like most woodworkers, want to build a more traditional workbench but I still have a s*#tload of laminex covered MDF, then I will probably replace the top and do my welding somewhere else to avoid burn marks...

Couple of shots, which also show off the variety of my collection of hand tools.

Scott in Peakhurst..

-

18th April 2007, 11:26 AM #43

When it was finished.....it is now surrounded by 20mm conveyor belt, after the #20 incident. I will be adding another LV holddown, and a tail vise, and a planing stop, and mebbe a dovetail vise using the holddowns on the front, and...

After about 2 yrs the top needs flattening - it has developed a 3mm cup for some reason.

i really like working on this bench, and that I recyled the timber for the legs from a 100yr old bridge.

I am happier working with it against a wall, though haven't really tried it in the open. I like the idea of having the tools on the wall in a cool cupboard, which is one of the winter projects planned.The only way to get rid of a [Domino] temptation is to yield to it. Oscar Wilde

.....so go4it people!

-

18th April 2007, 12:14 PM #44

Here it is, about 6', Canadian oregon top made out of 6 x 3's. I made it about 20 years ago and it has followed us around.

-

18th April 2007, 12:18 PM #45

Similar Threads

-

Melbourne WWW Show

By TritonJapan in forum TRITON / GMCReplies: 9Last Post: 25th October 2006, 08:31 PM -

@*&%$*! postjumping **&$@&%! - HELP!

By TassieKiwi in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 3Last Post: 27th April 2006, 09:33 AM -

Sydney Wood Show Vs Canberra Show

By I_wanna_Shed in forum WOODWORK - GENERALReplies: 8Last Post: 10th April 2006, 06:16 PM -

What did you buy at the wood show?

By soundman in forum WOODWORK - GENERALReplies: 16Last Post: 25th May 2005, 11:00 PM -

Melboure Wood Show Prices

By Sir Stinkalot in forum HAND TOOLS - POWEREDReplies: 4Last Post: 9th October 2003, 11:06 PM

Reply With Quote

Reply With Quote