Needs Pictures: 0

Needs Pictures: 0

Results 16 to 30 of 207

-

18th March 2017, 03:53 PM #16

good point

Don't know about Melbourne, but in parts of Sydney a property with gas heating and/or gas cooking typically was wired from a single phase and might only have 1 x lighting and 1 x power circuit.

It's also possible that the wires feeding the garage are only a nominal 10A. and that the sustainable current draw (due to marginal sized wiring) is less than 10A. It will pay to have a sparky check before purchasing too many tools.regards from Alberta, Canada

ian

-

18th March 2017 03:53 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

19th March 2017, 07:31 PM #17

Thanks All

A few answers - the house is a rental and the house is about 15 years old. Therefor I cannot not add windows or renovate the garage/house.

Having read what people have written it looks like it will be simplest to just add a heavy duty circuit to run the machines and as was statedplus the owner is okay/reasonable. This will solve all ambiguity regarding juice. I have been in this house 5 years and I can see myself staying for another 5.Unlikely that the owner of the house would object to this sort of improvement.

I had a look at the switchboard - bare bones, one master switch, two switches labeled power, one switch labeled lights, one for oven, thats it.

I would prefer 3 phase machines and I have looked into Phase Change Converters. What problems would I face with such an option?

I am left handed yet I switch back and forth between the two.

I do not own a mitre saw, for ruff cutting to length I have a panel saw and two saw horses, they take up less space.

Wood storage will have to be in the house or outside the workshop under cover simple no space, and I cannot go adding timber racks.

I have two Krenov work stands that are ideal as temporary tables for storying tools & timber on.

I am single and unattached so no pain in the posterior to placate.You can also earn brownie points by stacking all the tools to one side of the garage so her indoors can get her car in there at times.

I do not own a lathe as of yet just planing long term.

I can see the advantage of having a bunch of stuff on wheels.

FenceFurniture I will draw up your layout suggestions when I have some time this week.

-

19th March 2017, 08:12 PM #18

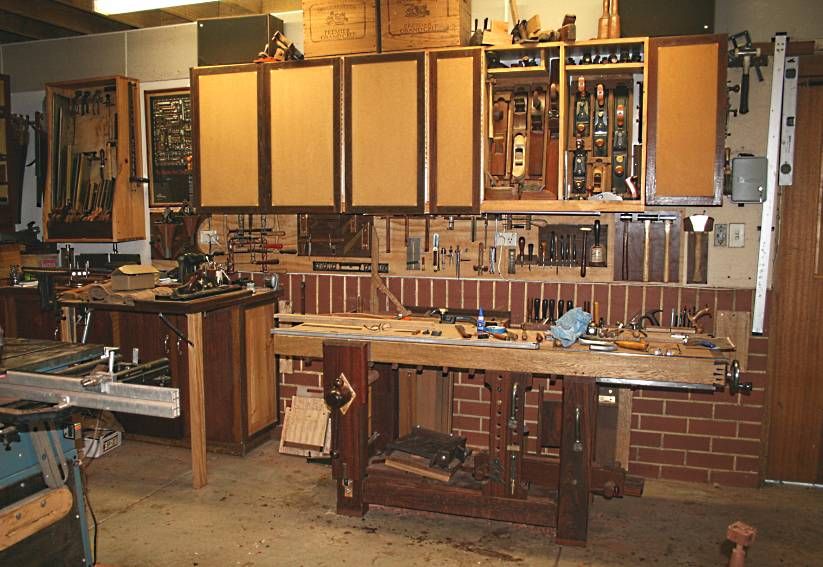

With regards layout, I also have a double garage, and park one car (mine!) inside at the end of a day. The standing power machines you mention are essentially what I have. So, for interest ...

From the garage door end, right hand corner (facing the garage door): combo thicknesser-jointer, bandsaw, 2 hp dusty (no, it does not exhaust outside. I cannot do this. I open the garage and rear door to clear the air), floor standing drill press. At the front you can see my old tablesaw with sliding table ...

Panning across, there is a small lathe at the far end, with a belt sander, and then the handtool cabinets ...

That would swing you around to the other end of the workshop. Note that I use the walls for tools that need to be grabbed frequently ...

The tablesaw has an integrated router table, which saves a lot of space ..

Cabinets get a lot out of the way. Keeping them up high provides useable space below ..

Shooting is done at a space auxiliary bench ...

To the left of the photo below is the entry door, and it is on the same wall as the bench. This is my dedicated sharpening centre. I plumbed in running water purposely for it ...

With the car out, there is plenty of space for wheeling out saw horses or trestles. Everything is on wheels anyway, so it remains a fluid and flexible work area.

Wood is stored near the garage door. Since taking these shots, I have built better racks (using the Triton system) ..

Hope this helps with ideas for placement.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

19th March 2017, 11:59 PM #19

I took most of the advice from FenceFurniture. Especially the placement jointer / tablesaw & bandsaw close to the dusty to reduce the ducting distance. This also gives me the option to handle long stock through the rear door and roller door.

Derek reminded me to include the dedicated sharpening station. The bench light & the shop vac.

-

20th March 2017, 12:31 AM #20

Yes, that is why mine are group close together.Especially the placement jointer / tablesaw & bandsaw close to the dusty to reduce the ducting distance.

Yes, that is why mine are group close together.Especially the placement jointer / tablesaw & bandsaw close to the dusty to reduce the ducting distance.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

22nd March 2017, 10:28 PM #21

I am now considering ducting for dust extraction.

This is my private workshop - I will be the sole user and will never use more then one machine at one time.

The dust extractor I am looking to purchase Timbercon Sherwood 2HP Industrial Dust Extractor it fits my budged.

Then I plan to modify as per BobL instructions here.

From the limit amount that I have been able to assimilate this is what I have come up with.

Looking for feedback.

Since I rent I cannot hang ducting from the ceiling would it be feasible to run 150mm diameter PVC pipe on the floor between the machines and the wall.

Shown in red in the drawing.

Then use 150mm flex hose (shown in blue) from the exit port at the back of the machines connecting the PVC pipe. Then run Flexible Dust Hose from dust extractor to the start of the PVC pipe.

My reasoning is that the PVC will not reduce suction as much as meters of Flexible Dust Hose also its cheaper then hose.

Another question is there much difference between Flexible Dust Hose? Some stuff is plain, some has steel wire, some has copper wire prices vary from $30 to $40 a meter.

-

22nd March 2017, 11:57 PM #22

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,792

This DC does not need any modification - it already has a 6" dust port and the impeller mounted integral withe the filter bag housing.

You need to be aware that it is quite noisy and I would find out about this.

Don't bother asking Timbecon about it.

Ask on the dust forum.

Its far from the best but there is not much else you can do.Since I rent I cannot hang ducting from the ceiling would it be feasible to run 150mm diameter PVC pipe on the floor between the machines and the wall.

AT the door way to the back you will have to fit a removable panel across the door that has a hole in it otherwise the fine dust is going to go straight back inside the shed.

Something like a heavy plastic curtain might work.

CorrectThen use 150mm flex hose (shown in blue) from the exit port at the back of the machines connecting the PVC pipe. Then run Flexible Dust Hose from dust extractor to the start of the PVC pipe.

My reasoning is that the PVC will not reduce suction as much as meters of Flexible Dust Hose also its cheaper then hose.

For that reason I would look at making the connection between the DC and the section inside the shed out of hard PVC - it should not be too hard to lay it out when you need it.

It depends on the length used - there won't be that much difference for short lengths but if longer lengths are used then the smooth walled stuff is better,Another question is there much difference between Flexible Dust Hose? Some stuff is plain, some has steel wire, some has copper wire prices vary from $30 to $40 a meter.

-

23rd March 2017, 12:05 AM #23

-

23rd March 2017, 12:14 AM #24

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,792

If you contain the extractor in a sealed box it won't work as the air has to go somewhere so it needs an opening.

The fine dust will come out of that opening and back into the shed.

You could add a chimney to the enclosure but it will need to clear the roof line of your carport.

-

23rd March 2017, 12:26 AM #25

Fudge

-

24th March 2017, 02:13 AM #26

Dust Extraction Questions:

My thicknesser jointer & tablesaw machines will come with 120 mm dust connection.

Now the dust extractor comes with a 150mm dust connection.

Would it be best to increase the dust connection from the machine from 120 mm to 150 mm. Then use 150 mm ducting from thicknesser jointer & tablesaw machines to the dusty?

My reasoning is that it this would avoid bottlenecks in the system.

The problem is finding a 150 mm fitting to fit the machine. Where would I find such fittings?

How much difference would it make in the real world having 120 mm dust connection connected at the machine to 150 mm flex hose / PVC running to the dusty?

-

24th March 2017, 05:56 AM #27

Your last design is missing the lathe.

-

24th March 2017, 09:38 AM #28

It may only be 30mm difference, but in cross sectional area it is a big difference. The ratio of surface area comparisons between 120mm and 150mm is 3600:5625 or 36:56 (½ the diameter squared in keeping with the area of a circle being Pi*r²). So 36/56 = 64% which means that the 150mm flex carries 50% more air, and that is very significant indeed in picking up invisible dust which relies on air volume for capture, rather than velocity.

Invisible dust is a double whammy: it is the dust that penetrates further into the lung tissue, hence is much more dangerous. At the same time - because it is invisible - we are fooled into thinking that there is no dust around and that the atmosphere is safe, and therefore are tempted into taking off the dust mask (if that is the chosen last wall of defence) or thinking that room purification is not necessary.

-

24th March 2017, 10:10 AM #29

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,792

Correct

The difference is VERY significantThe problem is finding a 150 mm fitting to fit the machine. Where would I find such fittings?

How much difference would it make in the real world having 120 mm dust connection connected at the machine to 150 mm flex hose / PVC running to the dusty?

DC impellers moving X cubic m of air through a 150 mm duct will only move 55% of X through a 125 mm bottleneck and around 34% of X through a 100 mm bottlenecks.

Two factors have to be considered

1) Getting air/dust out of a machine

You cannot purchase efficient connections specifically for this task and - you have to be prepared to remove the old port and replace it with a bigger port.

Removal may require using an angle grinder to cutting into the cabinet. Some woodworkers are not comfortable with doing this especially on a new machine.

Some large size PVC plumbing parts can be adapted - seen second thread below.

2) Allowing enough air to get into a machine

Additional holes are usually needed to be cut into cabinets to allow air to get into the cabinet to sweep up the sawdust.

An example of #2 is this in a BS cabinet like this Band saw port grills

There is a thread dedicated to all this in the dust forum

Improving machine cabinet dust ports

On some machinery the major parts of the dust extraction system inside a machine needs to be completely rebuilt to meet both factors above.

An example of this is most combo jointer/thicknesser machines that have a choked dust collection chamber

The generic 2HP 10" planer/thicknesser dust control issues

Some of these things are beyond DIY wood workers who have to unfortunately live with what they have.

This thread is better suited to the Dust forum rather than here.

I suspect you need to spend a couple of hours reading through some of the newer longer threads in the Dust forum where you will see a lot of ideas for improving dust collection from machines.

Just beware that many posts (especially the older ones) are riddled with misconceptions.

The most common misconceptions are

- running 6" ducting all the way to machines and then using 4" connections is OK - It's not, it's a complete waste of time.

- 2 x 4" ducts = 1 x 6" duct - no so - it takes 3 x 4" ducts to equate to the flow of a 6" duct.

- 4" ducting is OK - it is on some machines like a DP or a small sander or a power tool, but it's not enough on TS, BS, jointers etc.

- relying on visual indicators is a reliable way to determine effectiveness of dust extraction - not so. Testing by DIY folks is expensive, difficult, boring and very time consuming. About the only thing left for DIY is to heed to advice of folks that have done the measurements like BP.

-

24th March 2017, 06:05 PM #30

Senior Member

Senior Member

- Join Date

- Apr 2012

- Location

- Thornton NSW

- Posts

- 456

Lots of good advice here. One thing I will say from my own experience is that the size of the machines etc is only half the story, you have to give equal or more weight to the space around the machines. For example, your table saw takes up X amount of space but you need to allow enough room around it for what you plan to cut. An over/under planer thicknesser feeds from opposite directions, so you have to allow the space to feed in thicknesser mode which is lower. Also, if you put machines on mobile bases, try to do this so their work surface is all at the same height. This will allow you to use your workbench as an outfeed table for the saw or router table.

Another thing you might consider is if the garage door is a panel lift, you will have brackets suspending the door tracks which could be used to hang a duct across the garage. This might give you a bit more flexibility in machine placement without making irreversible alterations.

Similar Threads

-

Dust extraction layout ideas wanted.

By Albert in forum DUST EXTRACTIONReplies: 1Last Post: 14th August 2013, 05:46 PM -

Layout ideas

By Stiebs in forum THE SHEDReplies: 6Last Post: 26th March 2011, 06:36 PM -

New Workshop Layout

By Lumber Bunker in forum WOODWORK - GENERALReplies: 4Last Post: 9th March 2008, 11:55 AM -

Workshop Layout

By Jim Grant in forum HAND TOOLS - UNPOWEREDReplies: 23Last Post: 28th February 2005, 12:11 AM -

home workshop layout

By jow104 in forum TRITON / GMCReplies: 1Last Post: 29th April 2003, 04:08 PM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote