Needs Pictures: 0

Needs Pictures: 0

Results 16 to 30 of 31

Thread: Laguna 14-BX feedback wanted.

-

7th March 2016, 11:40 PM #16

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Dec 2012

- Location

- Australia

- Posts

- 684

I've been reading this closely and am very happy I have as I was planning on purchasing one of the 14 SUV's next month and I think you've sold me on one. Can't wait. It will be my first bandsaw.

-

7th March 2016 11:40 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

8th March 2016, 09:44 AM #17

-

8th March 2016, 09:50 AM #18

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Dec 2012

- Location

- Australia

- Posts

- 684

That was the main reason I went for it as I compared similar priced models with the same features and there weren't too many around that weren't a lot more expensive and it is still quite a small unit in comparison to some others that have the same power.

-

27th March 2016, 05:41 PM #19

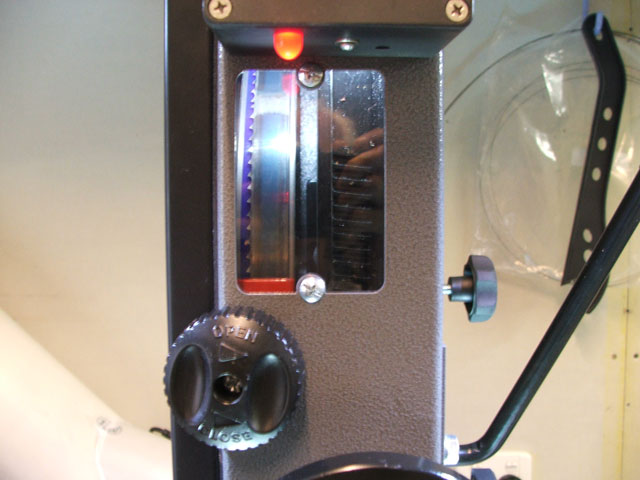

Had an 8 day road trip and now back to finishing the bandsaw installation, I have a few jigs to make for cutting some small logs, cutting and trimming bowl blanks, a circle jig etc, but before getting into that I decided to fit two small led assembles inside the top cabinet, one for viewing the blade tension indicator and one for the viewing the wheel/blade through the blade tracking window. Both run from 12v and were simple to install and connect trough an existing unused mounting hole for the front light fixture, I have small diecast box mounted there with an existing 12 volt source inside for my Led table lighting system that is attached to the top of the diecast box.

I didn't realize how useful these two internal cabinet light would turn out to be until I actually used them, it really adds a nice touch.

I also had an idea and for a bit of fun decided to revisit the subject of bandsaw vibration, it's often said that a bandsaw is likely one of the most vibration prone pieces of workshop equipment, and although I had finally removed the initial vibration problems I had with the saw, I was interested to see if was possible to get it even better. One thing we / I don't know are the tolerance values manufactures allow for in tooling and assembly of these machines.

Is every wheel balanced to the same value? Or is there a limit that is set and above which, a wheel is pulled and rebalanced to meet the limits? Are they even tested at all?

From my point of view, static balancing is not going to work on a new bandsaw due to bearing tightness, and with heavy cast wheels you would need to be out of balance quite a bit to try and fine tune the wheel, even then nothing really compares to running a bandsaw at operating speed to adjust wheel balance.

I feel that dynamic balancing is the way to go and this actually turned out to be very simple, it was surprisingly quick to do with the right tools. The first thing needed is a dial indicator, in a previous post I mentioned the ballpark price and the one I used. I now feel that the magnetic mounting hardware is worth the extra price, the combined dial indicator and base I bought are just brilliant.

The second thing that made this task simple was a set of rare earth magnets from Jaycar. There are 4 very small 10mm x 3mm magnets in the packet, part# LM-1622. These will hold their position anywhere around the cast iron wheel. There is no way they will shift unless you physically pry them off.

To start with, I removed the blade and set the dial indicator against the side of the table. The dial indicator must be mounted to a solid object separate from the bandsaw, the complete mounting and dial gauge must be rigidly mounted and free from any movement.

Note: To me the front of the bandsaw is the side facing the wheel, and the side of the bandsaw is where you stand to look through the blade tracking window.

I marked a random reference start spot on the lower wheel, powered the saw and measured the amount of vibration on the dial gauge. I tried a few positions along the side of the table to find the position of most movement and noted the reading.

Stop the saw and place a magnet on the inside of the rim at the reference point. Re-measure the vibration, shift the magnet 45 deg clockwise and repeat, do this until you find the point of lowest movement on the dial gauge, mark that spot and move the magnet either side of the spot until you find the point of lowest vibration. Depending on how far out of balance the wheel is and if you can't find a low point, you may have to move the weight closer to the hub OR you may have to use two magnets.

These magnets are fairly light for the weight of the wheel and even when placed at the extreme outside edge and in a position of worst vibration, the difference was only around 0.05mm (0.002") on the dial gauge.

It took me around 3 minutes to find the sweet spot and get the dial gauge reading down from 0.01mm to the thickness of the dial markings, say around 0.003mm, or from 0.004" down to 0.0001"

To balance the upper wheel, I fitted a very small blade in an attempt, as much as possible, to eliminate the blade from the equation.

Obviously!!!!!! - you have to be very careful with balancing the upper wheel as it involves running the saw with a blade fitted.

Again it only took about 6 attempts to get close to the sweet spot.

Side movement (vibration) was now down from 0.05mm to 0.005mm, or 0.002" reduced down to 0.0002"

With a 20mm (3/4") blade I now have 0.015mm or 0.0006" on the dial gauge.

Previously with a 13mm (1/2) blade I had 0.07mm or 0.003"

The 20mm blade @ 0.015mm - 0.0006" now has less vibration that the previous 3mm - 1/8" blade reading, which was around 0.03mm - 0.0012".

The only thing I can feel now is the induction hum of the motor.

If you already have a dial gauge, then for the cost of a set of magnets it's definitely worth a try and involves no modifications in any way to the bandsaw.

Again this was not to fix a fault, it was just of interest to me to see if it was possible to better the manufacture tolerance of an already balanced set of wheels.

My wife uses a number of different bandsaws at the club, her first comment when using this BS was this 14BX is so much smoother and has a high quality feel about it when compared to all the others she has used.

-

31st March 2016, 11:44 AM #20

Member

Member

- Join Date

- Dec 2015

- Location

- melbourne

- Posts

- 83

Thanks MandJ for the balancing tip.

I got my 14bx before Easter, been running great so far. Only problem is the fence is warped out of the box, managed to change a better one with the supplier but still not dead flat.

Is your fence flat?

-

31st March 2016, 12:23 PM #21

Hi, great to hear from another BX owner, there was a slight variation, more of a slight twist, I just put it in the vice sort of tweaked it, it's ok now.

-

6th August 2016, 05:34 PM #22

Member

Member

- Join Date

- Jun 2016

- Location

- Brisbane

- Posts

- 72

Thanks for the great thread. Heaps of info in here. I'm deciding between the 14BX and the SUV (or their Harvey equivalent). GregMach tell me that the fit and finish on the BX is supposed to be better than the SUV and from this thread I'm wondering if that was just a line to steer me towards the BX because they are out of the SUV's. The brakes on the BX do look better but the 3hp motor, beefier construction, wider blade capability, and greater resaw capacity has me leaning towards the SUV. The smoother winding action, the side mounted dust port, and accessory GPO of the BX arepluses in its column. Decisions, decisions !!!

-

8th August 2016, 07:24 PM #23

So that's how you change this field...

So that's how you change this field...

- Join Date

- Aug 2012

- Location

- Emu Plains, NSW

- Age

- 40

- Posts

- 136

Hey MandJ,

Could you take a snap (or two) of the under table dust collection you mentioned a while ago?

I've got a 14BX and as you've said, the in-cabinet dust collection is pretty good, but I've got shagloads of dust coming from right under the table.

-

10th August 2016, 09:04 PM #24

Hi, the BX is actually better then a lot of them, it's a problem with the design constraints of a consumer bandsaw. Here is link with lots of pictures: Beginner attempt at DC - thanks to forum members

On previous posts in that thread you can see the progression to this final design.

-

10th August 2016, 09:16 PM #25

Hi, I've read a few threads where owners have said the BX was a better finish that the SUV. I quess it depends on how big the timber is you are likely to cut, and the need for a wider blade, nothing I have cut so far has been able to slow the 2.5HP motor on the BX. BTW the foot brake on the BX is brilliant, instant stop and very little effort to activate.

-

10th August 2016, 09:41 PM #26

Member

Member

- Join Date

- Jun 2016

- Location

- Brisbane

- Posts

- 72

That's what the guys at GregMach said as well, but now I see that that the Harvey version of the SUV is selling for $1999 !!! So it's cheaper than the BX with greater resaw and blade capacity. I'm starting to lean towards that machine. They didn't have the SUV on the floor but the 18" version didn't look too bad. The height adjustment wasn't as smooth as the BX though....

-

21st December 2016, 11:16 AM #27

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jul 2014

- Location

- Brisbane

- Posts

- 935

I'm a little late to this and I haven't used my BX all that much - there some issues that I think I'll need to address but overall, even at the price, the BX is a very good bandsaw. The finish of similarly priced bandsaws seem a bit lacking, which is sad considering these things aren't cheap. I work out of my garage so 18" would be overkill. The BX has cut through spotted gum with no effort, so I have no complaints about it's power.

Also late but thanks for your detailed write ups MandJ, very much appreciated.

-

21st December 2016, 11:42 AM #28

Yes, I've had no problems at all with the BS once I got the few easily fixed slightly annoying things sorted, FYI I've just added a pressure switch to the lower cabinet to detect any problems with the dust extraction, thing like the blast gate to the BS closed, another blast gate open at the same time or low extraction flow rate. with the modified dust pickups and extraction on this BS it is still spotless inside and out - see last post for picture of dirty lower cabinet.

Sensitive vacuum switch for DC ducting.

-

21st December 2016, 12:36 PM #29

I've the SUV14 and wouldn't mind doing the dynamic balancing to smooth it out.

How did you attach your dial meter to something solid to measure the wobble? Where did you poke the saw with it to take the measurements?

Overall, I tend to agree with your assessment of saws and their prices. For an important machine, there are many small things that are lacking. Finish is a good start, but there are 100 compromises that seem so unnecessary and detract from what would be a brilliant machine.

The only people who would say woodworking machines are fantastic in quality are those who have never worked in IT. Even the most basic thing has a quality control that is easily 40,000 times better than anything I've ever seen in woodworking - with the sole exception of Festool.

How can one spend $3000 on a bandsaw and the fracking TYRES arent fitted properly?

How can one spend $3000 on a bandsaw and they WHEELS aren't balanced?

These two things, other than the motor, ARE the bandsaw! Get them wrong and its a mess.

On the SUV14 I could be critical of about 10 things. (why 7 ////different//// allen keys! Why a HEX BOLT to tension the motor and not an Allen key! Why is the tilt adjustment so pathetic... why no basic sensor on the tension arm/lever to avoid loose-starts? The underside guides are almost impossible to get too..... plus dust, dust, dust!)

What is most disturbing is that the "experts" who do reviews that carry on like pork chops over the "improved" dust collection! One can only imagine how absolutely rubbish their previous experiences must have been in order to claim what is an entirely-rubbish solution is somehow an "improvement".

Might buy some Carter tyres

-

21st December 2016, 02:53 PM #30

The magnetic base for my dial gauge was placed on one of those heavy steel sawhorse / camping system devices. I measured vibration from the side edge and the front edge of the cast iron table, it's interesting that the wheels don't stay synchronised. IE If you place a mark on the top side of each wheel and run the saw for a few seconds and recheck, both marks will no longer line up with each other at the top. You can get some funny phased resonances as the blade slowly changes position and it's inherent imbalance either adds or subtracts from any slight wheel / machine imbalance.

I first balanced the lower wheel by itself (no blade) and never touched it again. I then set the top wheel for least indication, however it's important to do this with a really small blade in order to take the blade out of the balance equation as much as possible, obviously some bad or poor quality larger blades can have a very noticeable effect on vibration.

I can say that I never notice any vibration at all now, I feel you can be overly critical when focusing on just one thing, but I think a valid test is this: If you turn on the BS to cut something and you are focused on the job at hand AND you are totally unaware of any residual vibration, then you can't ask for more than that.

I can say that I am extremely happy with the Laguna BX now, it is a joy to use and it tracks 100% true for me - I don't even know what all this talk about blade drift is. I track the blade gullet as close to center as I can for a given blade width, I find I have to tension the blades on the low side of the tension indicator, there appears to be a ton of reserve tension available in this BS, I never have to adjust the tracking once it's set unless I change a blade, love the guides, and if you have seen my posts on the dust extraction modifications, you can get almost 100% dust removal from the entire bandsaw in most cutting situations.

Once I made a nice cross cut sled, I found we were using this BS for just about all cutting jobs because it was just so nice to use - no dust, no cleaning up and quick, fast, accurate and smooth.

Similar Threads

-

Feedback on Laguna 12/14 bandsaw needed

By Dengue in forum BANDSAWSReplies: 27Last Post: 10th May 2017, 08:50 PM -

Jet or Laguna

By Superbunny in forum BANDSAWSReplies: 10Last Post: 25th November 2015, 03:16 PM -

Opinions on Laguna 6" and/or 8" Wedgebed HH jointers wanted

By aarggh in forum PRODUCT REVIEWSReplies: 3Last Post: 11th August 2015, 06:22 PM -

Carba-tec sbw 4300CE feedback wanted

By skippy in forum BANDSAWSReplies: 2Last Post: 16th December 2010, 02:42 AM -

Feedback wanted - Yr 9 Students working at Sydney Timber Show

By eddie the eagle in forum WOODWORK - GENERALReplies: 3Last Post: 27th June 2009, 10:44 AM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote