Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 12 of 12

-

18th April 2006, 04:54 PM #1

Novice

Novice

- Join Date

- Apr 2006

- Location

- Palmerston Nth

- Posts

- 16

Newbie intro...bandsaw guides...where

Newbie intro...bandsaw guides...where

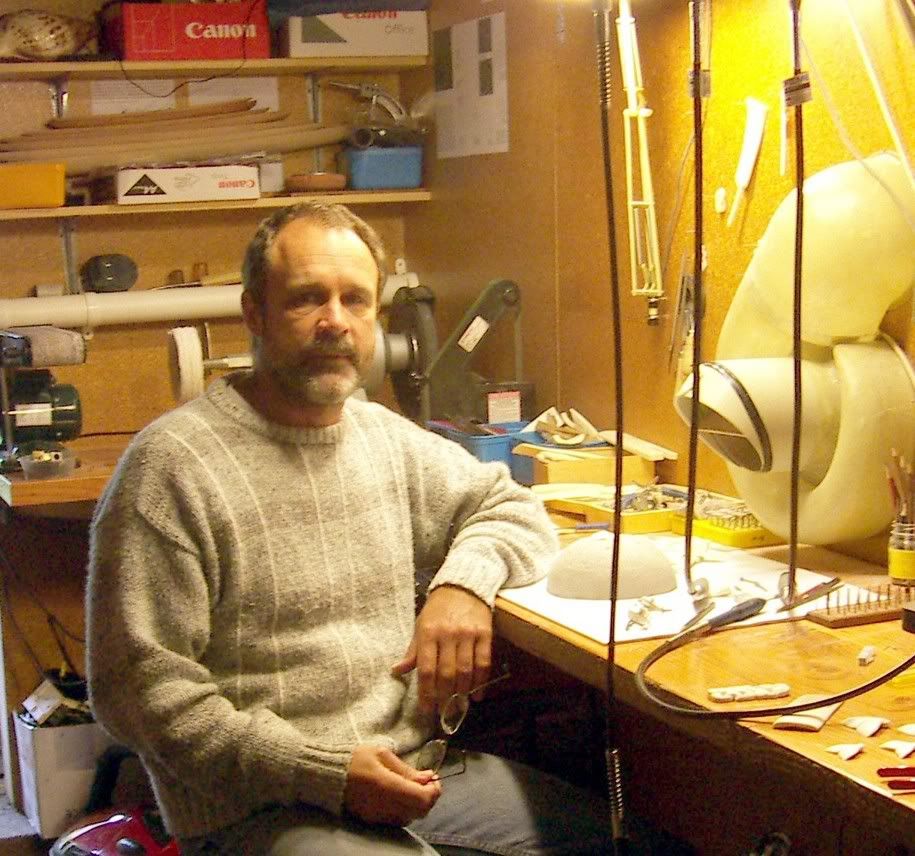

Hi guys...new to the forum and thought it polite to introduce myself.[IMG]

[/IMG]

[/IMG]

I'm a NZ maori carver...carving fulltime the last 3 years, mostly bone as decent carving native wood has been tricky to get...I've spent a fair bit of time recovering logs from my local river here in Palmerston North and ready to rumble with a good cache seasoning/drying under cover...some of the logs I have have been est from a few hundred years to a couple of thousand having been buried in the bed of the river...this in itself posses a number of problems the biggest being the outer cracks etc being full of course river sand so local mills won't touch them...

I've got a large Pantograph for routering out presentation type boxes for my carvings and just bought a bandsaw...un beknowingly a butchers saw...which I need to modify in adding decent band guides in place of the rudimentary steel slotted blocks top & bottom...any suggestions.

I'm also looking to build a bandsaw arm to attach to one of my chainsaws (90cc Dolmar) so I can slab my logs (up to 40" dia), the larger ones I rip in 2 down the middle so I can handle them i.e this Totara uncovered in a one in 100 year flood 2 years ago

Thats a Husq60 with a 20" bar to get an idea of the size...the pith down the middle is only about 4" of dozey wood...apart from a few minor shakes at the near end, the rest of the log is clear and sound.

I'd like to be able to bandsaw these logs to save waisting precious wood...think its a better long term option...any opinions out there

-

18th April 2006 04:54 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

18th April 2006, 06:31 PM #2

G'Day,

I thought it was illegal to carve Maoris these days... Seriously though, I took a trip to NZ a year or two ago and met a really great (Maori) carver - some really cool stuff is made and I gave it a go - and gave up...

Seriously though, I took a trip to NZ a year or two ago and met a really great (Maori) carver - some really cool stuff is made and I gave it a go - and gave up...

Anyway, welcome to the board.

As for your post, well there are a lot of questions there and a lot that could be mentioned. First of all, I don't know if a meatsaw is properly set up for cutting wood - ie the speeds may well be wrong.

The sand will also kill your blades (just as it would kill miller's blades).

The guides for a bandsaw are a bit of a personal thing... Everyone will recommend different guides - just search the forums and you will find how many conflicting bits of advice there are. :confused:

For my bandsaw I use the follwoing set up:

Top guides:

Back bearing - top quality bearing as this can't be fudged.

Side bearings - I usually use oily hardwood specially machined blocks.

Bottom guides:

Back bearing - best bearing I could find that was sealed and would fit.

Side bearings - I usually use oily hardwood specially machined blocks.

NOTE: Self-made wood blocks operate similar to the phenolic blocks or "cool-blocks" you can buy and can be butted hard up against the blade, but for wide blades a set of side bearing are worth considering.

Anyway, that is my advice.

Cam<Insert witty remark here>

-

18th April 2006, 06:49 PM #3

Welcome Errol.

What's that organic looking spiral thing on the wall at the back of the bench?

Sorry, can't help with bandsawing logs that big. I've got bearing guides on my little BAS350. Seem to work OK.Those are my principles, and if you don't like them . . . well, I have others.

-

18th April 2006, 06:56 PM #4

Welcome Errol,

Have a chat to a blade supplier, people like Henry brothers in Sydney or somebody local in your area they may be able to help you out with the blades as well as runners.

In the mean time I'd be interested in the following when you get it finished.

Himzo.I'm also looking to build a bandsaw arm to attach to one of my chainsawsThere's no such thing as too many Routers

-

18th April 2006, 07:57 PM #5

I have a meat saw that I have used to rough out blanks for wood turning.

It works but it is VERY rough.

Without properguides it blade wanders all over the place & bows as well.

I bought a proper bandsaw.

Do you have a lot of logs to slab?

Would it be better in the long run to pay somebody to slab them for you?Cliff.

If you find a post of mine that is missing a pic that you'd like to see, let me know & I'll see if I can find a copy.

-

19th April 2006, 11:55 PM #6

Butchers bandsaws

Butchers bandsaws

G'day Errol.

I've also got a Nolex butchers bandsaw that I've considered using. I've not looked at mods on guides etc but will research more after this thread.

I'm interested to see a pic of the pantograph you use. If you're electronically minded you could check out Rodm's CNC thread.

http://www.woodworkforums.ubeaut.com...ad.php?t=24299

Enjoy the forum

David

-

27th April 2006, 10:56 AM #7

Novice

Novice

- Join Date

- Apr 2006

- Location

- Palmerston Nth

- Posts

- 16

Thanks guys for taking the time...just for a little more info on what I'm doing,

some of the logs I work are Black maire...not quite as hard as some of the hard woods you have in oz but close, and like using a chainsaw on the stuff, slow (cool) is better so the speed of the bad should suit better than a wood workers bandsaw, especially with deeper bands that can expand with head at the teeth side and cause a sort of bowing and running off the wheels...but we'll have to see...just a matter of putting a bigger primary pulley on to speed it all up. Also the meat saw I have has a much heavier and stiffer frame than any of the wood saws I have seen to date...12" wheels with a 20" high throat which I can increase a further 3" quite simply with a little work...large water proof bearing blocks which will take quite a bit of tension if needed. Being waterproof I could use water feed for cooling and cleaning at the cut

As with anything ground breaking, although I wouldn't have thought it ground breaking...getting the cuts just the way you want it, usually better to do it yourself so rather than end up waisting precious logs ! !.

so rather than end up waisting precious logs ! !.

I have several chainsaws and have seen chainsaw mills in action...not terribly effective in hardwoods, especially when constant sharpening is required...carbide tipped chains are as expensive and anything you can find and I thought a bandsaw attachment would be a much better way to go, certainly cheaper and will cut more effectively than a chainsaw mill with less waiste. Ever tried to find anyone who knows how narrow a band you can get away with on a 40inch wide cut and control the tracking problem...been to saw mills and saw doctors...the problem is everyone that does experiment with this sort of stuff just go for the biggest blade they can accomodate and that always seems to be well within the safety margins (what ever they may be) of the bands being used...this approach would be OK for long service life in resharpens etc...but I've come to the conclusion that the blades tend to fatigue way before they wear to a point that the band begins to track/wander, then they just wind on more tension...so go figure :confused:

I guess I'll just make some guide blocks according to logic.

On thing...is the reason for rounding and polishing the back of a band, to do with it sliding past the rear thrust bearings and prevent galling on the bearing face?

-

27th April 2006, 11:03 AM #8

I think it is more to do with making round cuts so that the trailing end doesn't catch.

I think it is more to do with making round cuts so that the trailing end doesn't catch. Originally Posted by errolc

Originally Posted by errolc

Not much of an issue for you - but I may be wrong.

Cam<Insert witty remark here>

-

27th April 2006, 11:51 PM #9

Novice

Novice

- Join Date

- Apr 2006

- Location

- Palmerston Nth

- Posts

- 16

My patern makers Pantograph...was used by a shoe manfacturer for forming shoe sole molds...the copy table is at the top...its old but good...10 - 30,000rpm, up to 10mm collets, weights 440kgs and was a mission to get off the trailer when I got it

Zenwood asks " What's that organic looking spiral thing on the wall at the back of the bench? " can't work out this darn quote thing

its a 6" dust sucker...this is my workshop for carving bone pendants and the like...its under the house and gets a bit cold in winter...the sucker extractor draws the bone dust away and blows it into a cavity in the wall...dumps the heavier particals in a sealed catch tray and it recycles out a vent at the top of the wall, through an air filter off a Nissan Skyline Turbo

extractor draws the bone dust away and blows it into a cavity in the wall...dumps the heavier particals in a sealed catch tray and it recycles out a vent at the top of the wall, through an air filter off a Nissan Skyline Turbo  and back into the workshop so I don't loose my nice warm air, speed controlled to manage the hummmm and stop loosing my carvings

and back into the workshop so I don't loose my nice warm air, speed controlled to manage the hummmm and stop loosing my carvings

Cliff Rogers Q: Do you have a lot of logs to slab? Would it be better in the long run to pay somebody to slab them for you?

No one wants to touch them...the woods quite expensive if you have to buy it so financially its worth it to me...the log in the pic is 1 of 6...and I have another dozen or so about half the size & 6 to 7 mtrs long.

-

28th April 2006, 12:46 PM #10

Senior Member

Senior Member

- Join Date

- Dec 2004

- Location

- Brisbane

- Posts

- 464

I have a client in Brisbane who can help you with slide bars to which you can attch chainsaws. You are welcome to contact me.

I have a client in Brisbane who can help you with slide bars to which you can attch chainsaws. You are welcome to contact me. Originally Posted by errolc

Originally Posted by errolc

cheers,

conwood

-

11th May 2006, 05:32 PM #11

Senior Member

Senior Member

- Join Date

- Apr 2004

- Posts

- 383

Hi Errol,

for someone who is more local with blades, GP Sawdoctors in East Tamaki, 17 Andromeda Cre East Tamaki Auckland Phone 0-9-274 1700, are terrific as they can make the blades up to any length you want. They also have a range of industrial blades for longlife and can advise on their use with NZ timbers. Their prices are realistic as well as they are 2 blokes in an industrial unit.

As regards buying bandsaws in New Zealand, I did a lot of investigation a year ago when I was looking for a 16" unit (had dreams beyond my workshop size ). Drop me a private message and I'll let you know my findings so as not to bore all the Aussies.

Cheers

PaulNew Zealand

-

11th May 2006, 05:35 PM #12

Paul,

There are plenty New Zealanders here too mate (not me though ). If you post the info. here, then in the future someone else might come along and find it useful too. Don't worry about boring us Aussies.

). If you post the info. here, then in the future someone else might come along and find it useful too. Don't worry about boring us Aussies.

Cam<Insert witty remark here>

Similar Threads

-

Roller Bearing Guides - Newbie Question

By prokofiev_2000 in forum BANDSAWSReplies: 10Last Post: 2nd January 2008, 10:09 AM -

Carter bandsaw guides

By monoman in forum BANDSAWSReplies: 5Last Post: 11th August 2005, 07:26 PM -

H&F BP-16A bandsaw Newbie advice

By jackruss in forum BANDSAWSReplies: 11Last Post: 4th June 2004, 07:53 PM -

Review - Spaceage Ceramic Bandsaw Guides

By Dean in forum WOODWORK - GENERALReplies: 0Last Post: 21st May 2004, 12:42 AM -

Bandsaw guides upgrade question

By Rod Smith in forum BANDSAWSReplies: 0Last Post: 30th September 1999, 12:59 AM

Reply With Quote

Reply With Quote