Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 13 of 13

Thread: Tell me I'm dreaming/crazy

-

10th November 2023, 01:38 PM #1

Novice

Novice

- Join Date

- Sep 2020

- Location

- Adelaide

- Posts

- 16

Tell me I'm dreaming/crazy

Tell me I'm dreaming/crazy

Hi all

Looking for honest feedback, and possibly convincing that this is a bad idea!!

I've wanted a bandsaw for a long time (decades!). I'm a home enthusiast, I make smaller things, a little woodturning, and enjoy using recycled and reclaimed timber. I've spent many hours reading here and elsewhere about bandsaws, know the Snodgrass method well enough, but also "spent some time" with Alan Holtham and Eth from stockroom supplies. I've dreamt of a Laguna 1412, and have kicked the tyres of a Rikon 10-326 on the shop floor. They both have their fans and detractors, but both seem to be well-regarded at the high end for the home workshop. However, both are expensive (relative to home use and my personal justification), and both are quite BIG. I have very limited space and need things to be wheeled in and out and stored with as little footprint as possible.

So, I've been looking again at the classic 14" Taiwanese made, cast iron BSs that pop up on Gumtree and FB quite regularly. Badged variously as Hafco, Carbatec and other 'brands'. All have ¾ HP motors, basic block blade guides, thrust bearings etc etc. One thing I really like is the smaller footprint and overall compact size (the 10-326 has such a long fence guide rail, that no matter how you might try to place the machine, it's taking up a lot of space).

I've started a spreadsheet to get my numbers right, and I've nearly convinced myself this could be a good idea...

-Bandsaw, looking at a Carbatec badged version in really good condition for $400

-New urethane tyres, assuming that the current tyres have flat spots due to years under tension $45

-New link belt (I know not everyone will be a fan, but the adjustability would seem to be a good idea) assuming the old belt has settled into an oval $50

-Space age ceramic guide blocks and thrust bearings (again, not all will be fans, but this seems to be the quickest and cheapest way to update, a full Carter bearing kit would be nice, but Down Under would be more than the cost of the saw), have priced these online, with shipping at about $100

-New tension spring, again assuming fatigue in the original $70

-Timber wolf 105" ⅜" wide 3TPI with a focus on some resawing capacity while not going crazy and expecting to adequately tension a ¾" beast, but maybe ½" too (I know a local supplier could likely offer as good/better option and maybe cheaper, but I'm being lazy and using prices i can find now) $85

-12" Riser block - perhaps the most controversial bit. I've read extensively about the Pros (mostly from people who have fitted them and used them) and the Cons (seemingly mostly from people who have not fitted and used one but don't think they are a good idea) and don't expect to be resawing a 12" slab of jarrah (anyone seen 12" wide jarrah recently!?), but would like to have the capacity to go beyond 6" $246

By my maths, I'm at $995 for an, underpowered yes, (but wait...) compact, first bandsaw with decent *theoretical* resaw capacity that will likely be enough for my needs to rip, resaw, cut a few curves, rough out some small bowl blanks and help me convert smaller bits of wood into timber.

The final kicker is a new 1.5 HP 4 Pole, single phase 1400rpm (which seems to be the RPM of the motor of many of these 14" BS when they have this detail) for $260 (possibly find one for less too), bringing the total (if I decide to go down this extra HP path in the future - the graded expenditure here is also appealing) to $1255. Most likely as not, this will not be a simple 'plug-n-play' swap, but I'm willing to do some work to make it work.

Again, I know that cast iron, especially with the riser block is not going to be as stiff as a proper steel frame Rikon, Laguna, Harvey etc with true 12-13" resaw capacity, but for the amount of use, and intended use, I could put up with slower feed rates and buying an extra blade or two to keep them sharp.

At $1255 I'm up against the Rikon 10-321 (which I've had a look at and they seem overall poor quality to me) and getting close to the Rikon 10-324TG at $1600 and the 10-326 at $2000 (both with the added cost of buying a decent blade), but the overall footprint of both of these is going to be a problem. The Hafco BP-355 at $1298 currently seems a good unit, but shipping to Adelaide looks expensive and I don't have a forklift to get it off the truck...

I can almost convince myself I'm mad looking at the older 14" cast iron models and trying to upgrade it, but then I look at the numbers again, and can convince myself that this is a more appropriate and economical way to proceed.

Sorry for (what is now) a very long post, and thanks to any who have made it this far and would like to share frank and fearless thoughts, I won't be offended if my ideas are shot down!!

Thanks, Tim

-

10th November 2023 01:38 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

10th November 2023, 02:25 PM #2

I had the Hafco 14'' cast iron frame saw for a while and as you have suspected the 3/4 hp motor is only good for smallish work. The saw itself was ok and even the block guides work better than they look. You can also use hardwood blocks in them and the saw runs very quietly. I looked into getting the height extension and a bigger motor but that put me in budget range of a new saw. In the end I opted for the BP 355. Had that for about 15 years now and still happy with it. 2 blokes can get one out of a ute and set up without a forklift. You would have to find the extra pair of hands as a lot of delivery drivers wont handle heavy lifting.

Regards

John

-

10th November 2023, 02:40 PM #3

I have an old generic cast iron 14" bandsaw; it is plenty stiff. I also regularly maintain and use a few generic Chinese 14" units (H&F, Carbatax etc) and a Laguna 14/16. Only the Laguna is slightly stiffer than the cast iron unit.

My 2c? If you have the money go a Laguna; otherwise pick up an old cast iron unit. The only mod I would add would be a Cobra spring and maybe a de-tensioner; I haven't bothered with mine and still use the crappy tiny aluminium fence but don't have any issues. I have a riser but haven't fitted it as I don't need the extra height at the moment.Nothing succeeds like a budgie without a beak.

-

10th November 2023, 04:00 PM #4

All other things being equal in your choices, I would choose one with the split in the table for loading the blade coming from the side rather than the front. I have an older Hafco 16" MJ344 and one of the few things I dislike about it apart from (I just looked at all of it), is this one feature. Pain in the butt removing/refitting/tuning the fence each time the blade is changed

-

11th November 2023, 12:52 PM #5

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- Éire

- Age

- 39

- Posts

- 300

None of the nicer saws have a table slot to the side, it's a sign of a cheap machine.

Here's some small Italian machines, sizes range from 400, 440, or 450mm wheel size.

They have the same footprint as anything else really, though get progressively larger thereafter,

so are about the size as the cheapest 20" far Eastern machines you'll find

eyJidWNrZXQiOiJkb25lZGVhbC5pZS1waG90b3MiLCJlZGl0cyI6eyJ0b0Zvcm1hdCI6ImpwZWciLCJyZXNpemUiOnsiZml.jpegacm snac.jpgSP400 £600.jpgmultico bandsaw.jpegN'RA 400.jpgJolly-45-4.jpghammer n440 small.jpg

400 quid s450.jpgScreenshot-2023-6-7 Bandsaw Tuneup- Laguna 16 Bandsaw Gets A New Woodslicer Blade and Dust Colle.jpg

Or a 4300mm cheapie large frame sized machines are about the same, and also some tightly cramped 20" are about the same size.You get the jist, and I'd rather spend my money on that, the good machines have cast iron wheels, the cheaper, then you'd need check that.

And, even if three phase, it'll give you all the resto vibes yer after, to make it yours.

Screenshot-2023-5-10 Band saw in Ellon, Aberdeenshire Gumtree.jpg

All the best

Tom

-

11th November 2023, 03:06 PM #6

-

11th November 2023, 07:26 PM #7

Tim, been there done that.

Today I have a Hammer N4400 18" bandsaw, which is as solid as a brick dunny. However, my first bandsaw was a Carbatec 14" about 20 years ago. This had a 6" re-saw and 3/4" hp motor. I added a 1 1/2 hp motor, which certainly gave it ooomph. Then I added a riser kit, and now the re-saw capacity was 12" ...

The problem was that the frame of the bandsaw was not stiff enough to carry the depth of cut. It could not take the tensioning needed for the height of cut. I sold the bandsaw, which was otherwise very decent as long as the cut remained at 6". Nevertheless, as long as the frame could not take more tension, better (carbide or bimetal) blades could not be used, and so the cut would remain mediocre regardless of all the power in the world.

The frame is more important than the power/motor. Get the most heavy-duty bandsaw you can.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

12th November 2023, 10:25 AM #8

My story is similar to Derek's in some ways. I started out with a Hafco 14". It wasn't perfect, but importantly, the table was flat. Apparently, they weren't always thus. I was able to set it up so that I could cut 1mm veneers in blackwood, to almost the full depth of cut, with a bi-metal blade. However, it was a slow process, and may have been made faster with a more powerful motor. It was important to keep the blades sharp. I was fortunate in being taught how to sharpen them.

Over the years I did have to replace a few things. I can't remember what the original block guides were, but I do remember replacing them with nylon ones. The casting that holds the tensioner broke, and examination showed a faulty casting. I also replaced the upper & lower bearings when one of them failed. I never tried a height extender, as I'd read of problems with flexing. However, I didn't have any such problems with the standard unit. I did fit an after-market fence.

Eventually, it was too small for my needs, so I sold it to a Mens Shed and replaced it with a Hammer N4400, with which I am very happy after about 15 years.

-

12th November 2023, 11:33 PM #9

Novice

Novice

- Join Date

- Sep 2020

- Location

- Adelaide

- Posts

- 16

Thanks everyone for all of the responses. You have confirmed what I knew in my head (bad idea, well perhaps not 'bad' per se, but at least sub optimal) but my heart did thrill to the idea of refurbing something old and making it into something worthwhile and 'mine'. Strong silk purse from sow's ear vibes from watching too many my mechanics videos on YT...

John, thanks for the BP 355 advice. Ticks a lot of boxes, but when I do look at the freight it adds hundreds, and I get stuck in a "what don't I spend the freight, plus a "little" extra and get a Laguna 1412" loop!

Chief, a valuable 2c, and with time a few more sales I'm hoping to get there.

mic-d, it's always struck me as an odd design choice to have the table split towards the front, especially those machines with the fence rail bolted on *both* sides of the table split

Tom, I've noticed front and side access in a range of saws, both cheaper and more expensive. All of the classic cast iron 14" Delta (I believe) clones from Taiwan have the blade slot to the side, while the "Full Boar" bunnings cheapie has the slot to the front. Those are some serious bandsaws on display! You're right about the resto vibes, I'll just have to find a different project I think!

Derek, thanks for your real world experience. I must admit I read your post and started to 'argue' "but what about just a ⅜" or ½" blade, surely it could tension that..." But I'm probably still at the 'bargaining' stage on this one... I think the tipping point for me was the idea of putting in still considerable dollars, lots of time, lots of hope, but still getting mediocre results that waste time and timber.

Alex, again, thanks for sharing your personal experience. I've since read and watched a few things about the casting that holds the upper wheel axle and manages the tensioning and wheel adjustment cracking. A hard part to fully inspect on the old cast iron BSs and lurking cracks could be trouble.

In all, talk of 15 or so years of happiness going for a more modern machine, and some buy once cry once thinking has me (mostly 😉 convinced.

convinced.

Thanks again to everyone for your time and thoughts

Tim

-

13th November 2023, 06:54 AM #10

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- Éire

- Age

- 39

- Posts

- 300

There's plenty of reasons to go looking for an Italian machine, none of which have a slot to the side.

I suggest some studying of those machines to see why that is.

Seems your on the right track regarding that, I for one can mention something from Novellara having super skookum castings,

not to mention some comical piccies of bent chassis from those who've used too long of a blade.

If that ain't a good test, then I dunno what is.

Not saying don't buy a Far Eastern machine, even a cheaper version of one with a slot to the side, (which has cast iron wheels, that is) for cheap,

but best to check it's got a common wheel size, ala the Italian machines, 400, 440, and 450mm standards since the '80's,

as you might find it more difficult to source replacements if you wished to buy stretch on types.

Don't omit a gander of the three phase market, and you'd be looking at spending much less money, factoring in a hundred quid VFD to run it,

but on a little saw like those, then the reasoning is for a bargain only, (most likely,but depending on extraction)

and the likelyhood of anything compared to the CO450 being guaranteed success, right off the bat,

that goes for brand spankin new or old, is pot luck, by design.

The CO , (one which has a foot mount motor) is the only way to be sure of anything,

other checks worth noting the wheels being balanced, and nothing missing or broken,

That would be the machine I'd be taking home, be it single or three phase.

CO 450.jpeg

That's for someone who would be quite bothered about making a flange mounted motor adjustable.

It's one of the ways I made me saw mine, and should I find another machine for a few hundred quid local,

I'd be doing the same thing again.

Partial Centaurolization if you will... well yes, if the machine was made from thick enough steel with trustworthy cast iron, that is.

Good luck on the scavenge!

Tom

-

13th November 2023, 01:43 PM #11

Tim ... you are crazy if, after decades of wanting a bandsaw, you buy a crappy toy.

Italian, yes.

LARGEST possible, yes.

You will not regret it.

IMO anyway. (H intentionally omitted) “We often contradict an opinion for no other reason

“We often contradict an opinion for no other reason

than that we do not like the tone in which it is expressed.”

Friedrich Nietzsche

-

13th November 2023, 03:48 PM #12

Hi Tim,

Perhaps another perspective for your consideration.

I think if you want to resaw wide boards, you should get the biggest machine you can possibly fit into the allocated space. I know the feeling of buying a smaller (16") bandsaw for the purposes of resawing ex demolition timber, only to be disappointed that it was unable to tension the blades needed for the job.

If you look at the second hand market, your money will go a long way.

Without knowing how much space you have to play with, my hunch is that you will get away with a much larger saw than a 14 inch model, unless height becomes a factor.

For example, I have a smallish shed, yet can easily fit a 30inch machine I bought for a couple of hundred dollars. Yes it needed a bit of TLC, however it has been going strong these last 70 odd years and there's no reason to think that it will give up the ghost any time soon. The wearable items like belts, bearings etc can be replaced provided the fundamentals are sound.

Others have recommended Italian machines, however there are a number of quality older English machines such as Wadkin and Robinson that I would recommend keeping an eye out for.

Cheers, Zac.

-

14th November 2023, 12:12 AM #13

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- Éire

- Age

- 39

- Posts

- 300

The C500 looks pretty compact, if a bit tall/tippy possibly, should one be thinking of making a deeper mobile base for it, might be a good thing.

$_86.jpg

Still much larger footprint that a compact Far Eastern machine though, much like all the Italian machines, space savers buying Italian might step things down a tad.

Here's me old new lemon what I had briefly before returning, one of the lighter duty offerings from the Far East,

with much smaller table and slot to the side, but featuring decent enough cast iron wheels, which is the most important part really, well that and the motor.

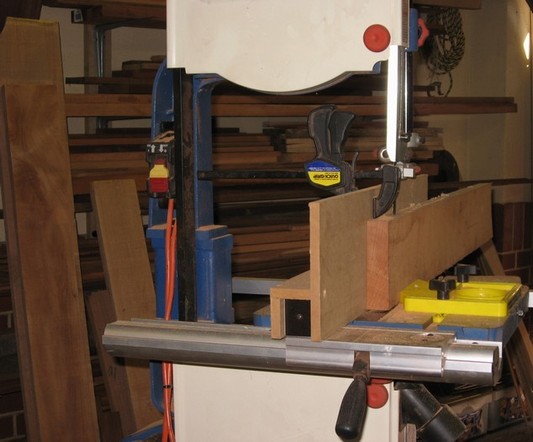

Checking for coplanar .jpg

Here's another shot of the same machine, from the back you might just make out the table size, quite small compared to some.

Far Eastern compact 20" bandsaw.jpeg

Many might agree a 500mm machine being one size more than they're after, but that's the usual rule of thumb anyway.

Not saying the table on the CO 450 isn't huge, compared to some in that size wheel range, but something with an adjustable motor deserves

an extra mention, should one stumble across one.

Also worth noting, the possibility of finding something old (welded steel frame old, not of the babbitt bearings era)

will probably feature vulcanized tires, as per most of the Italian machines...

and will likely be needing the rubber dressed to a camber again.

As a consequence, that might likely mean that these machines could've been used very briefly in anger, and tucked away into a corner and neglected thereafter, so there's likely the kinda machine out there for cheap, which would fit the bill.

Tom

Similar Threads

-

Tell them there dreaming !!!!

By Simplicity in forum FOR SALE on eBay and external sites.Replies: 17Last Post: 19th February 2020, 09:13 PM -

Just dreaming......

By Cal in forum THE SHEDReplies: 16Last Post: 16th February 2017, 03:10 PM -

You must be dreaming!

By DSEL74 in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 4Last Post: 14th August 2013, 08:52 PM -

Do-able or dreaming???

By TTIT in forum TIMBER & WORKING WITH WOOD SHOWSReplies: 13Last Post: 22nd May 2011, 11:07 PM -

Tell him he's dreaming

By 741Baus in forum SMALL TIMBER MILLINGReplies: 5Last Post: 23rd April 2009, 09:15 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote