Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 10 of 10

Thread: D8 panel saw refurbishment.

-

24th February 2015, 01:12 PM #1

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

D8 panel saw refurbishment.

D8 panel saw refurbishment.

Hi all. I purchased this panel saw around 10 years ago. Its a Disston D8 Panel Saw; 20" saw plate; 10 ppi; crosscut tooth. Its been wrapped in storage during that time period awaiting the day I could get around to refurbishing it.

That day had finally arrived.

The 1st job was to remove the ugly finish that the previous owner had hastily applied. Its rather bulky original handle shape was typical of its circa. I felt the need to include some reshaping to improve its general appearance.

http://www.disstonianinstitute.com/d8page.html

Before;

After;

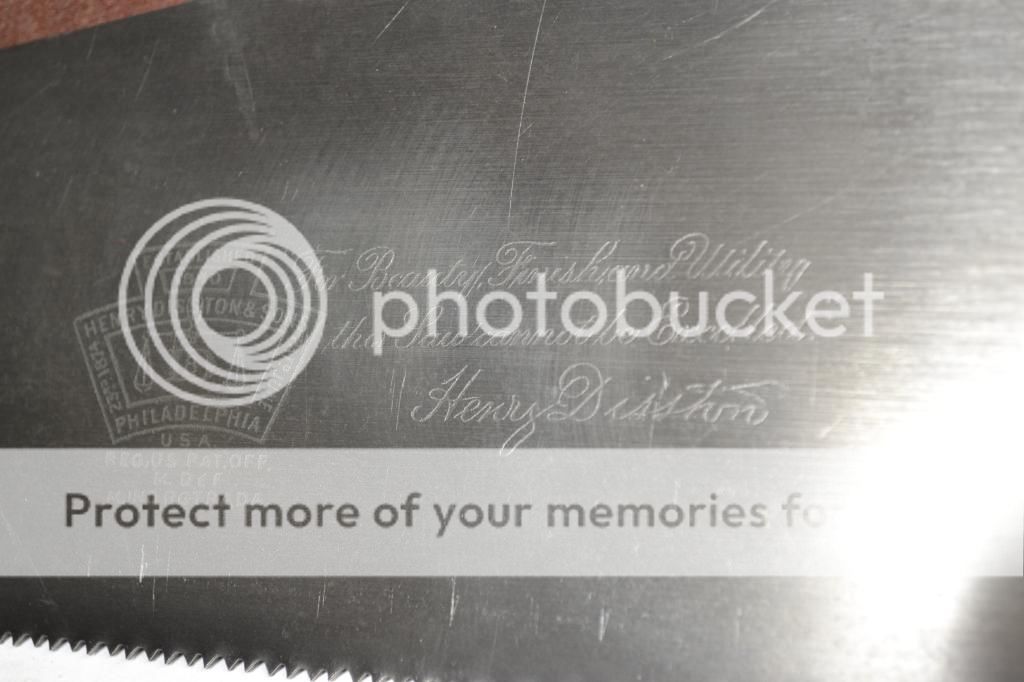

Next thing to do was darken the etching so it stood out more clearly.

Before;

After;

With the hyphenated etching, I was able to determine the age of the saw as being post 1928. The H Disston & Sons medallion that's has been fitted to the saw is clearly not original, as its use stopped in 1917. Not of great concern.

http://www.disstonianinstitute.com/etch.html

The saw teeth are in excellent condition, and will only require a light sharpen when time permits to allow this saw to be in excellent user condition.

I would appreciate your thoughts to the changes I made to the saw handle's shape.

regards Stewie;

-

24th February 2015 01:12 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

24th February 2015, 02:45 PM #2

Very nice work Stewie. Your mod's make diminish the blocky look of the handle and benefit the saw overall.

Innovations are those useful things that, by dint of chance, manage to survive the stupidity and destructive tendencies inherent in human nature.

-

24th February 2015, 03:10 PM #3

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

Hi Rob. Thanks for the feedback. Modifying a pre existing design comes with its many challenges. But overall I think the changes I made remained within the bounds of being tastefully not over done. It was a very worthwhile and enjoyable project.

regards; Stewie.

-

24th February 2015, 07:08 PM #4

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

Wow looks great! I love the finished product.

ive got two full sized D8s I'm goin to be working on soon. I posted about them and would be interested to hear your opinion on the matter.

cheers,

luke

-

24th February 2015, 08:40 PM #5

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

Hi Luke. Where I can offer some help via the open forum I am willing to assist. If you could post a couple of photo's of your D8s within the thread you have started would be of great help.

regards Stewie;

-

24th February 2015, 10:14 PM #6

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

Update. I have gone back and reviewed the information withinhttp://www.disstonianinstitute.com/etch.html . After 1928 the model no. would be etched as D - 8. This saw has the 8 etched inside the D. That translates to this saw being pre 1928, and the medallion is most likely correct for this saw.

regards Stewie

-

25th February 2015, 03:51 PM #7

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

-

27th February 2015, 09:48 AM #8

Sweet little saw, Stewie. There are a couple more lifetimes in it yet, by the look.

While I agree the old handles lack finesse, they were at least shaped enough to give a comfortable grip. I haven't felt obliged to re-shape any of my pre-WW2 Disstons, but I have certainly 'fixed' the handle on a 1950's ripsaw that I acquired from FIL's kit. The blade is good (& taper-ground), but the handle was decidedly substandard. Maybe some day I'll tart up the old pot's pre WW2 D8 a bit, but I sort of like it looking very well-used, as he left it....

CheersIW

-

4th March 2015, 02:03 PM #9

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

Hi all. This is the final presentation of the Disston D8 panel saw refurbishment.

The handle has had 3 coats of garnet shellac. Later buffed to a nice shine.

The saw teeth have been sharpened with a crosscut profile of 10 degree's side fleam.

I also completed some test cuts with the panel saw on both hardwood & softwood to insure the work completed on resharpening the saw teeth was of an acceptable standard.

regards Stewie.

Testing the saw on Oregon.

Testing the saw on Oregon.

-

4th March 2015, 10:39 PM #10

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

Zen Rules for Woodwork

http://www.woodreview.com.au/news/ze...for%20Woodwork

Similar Threads

-

The great handtool refurbishment

By michael_m in forum HAND TOOLS - UNPOWEREDReplies: 29Last Post: 12th October 2014, 08:54 PM -

El Cheapo Lathe - Refurbishment

By Bushmiller in forum WOODTURNING - GENERALReplies: 24Last Post: 6th September 2013, 01:20 PM -

Machine Vise Refurbishment

By Anorak Bob in forum METALWORK FORUMReplies: 10Last Post: 29th January 2013, 10:25 AM -

Pelin Cherry refurbishment

By Cherry_334 in forum BOAT BUILDING / REPAIRINGReplies: 8Last Post: 12th June 2010, 11:19 AM -

barking bar refurbishment

By footrot in forum SMALL TIMBER MILLINGReplies: 1Last Post: 22nd June 2009, 06:19 PM

Likes:

Likes:

Reply With Quote

Reply With Quote