Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 21

Thread: Bbandsaw advice please

-

28th July 2016, 04:28 PM #1

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2010

- Location

- Port Sorell, Tasmania

- Posts

- 592

Bbandsaw advice please

Bbandsaw advice please

Am looking at an old bandsaw on gumtree.

Large Bandsaw | Power Tools | Gumtree Australia West Tamar - Bridgenorth | 1114980724

The seller has confirmed that the silver looking mark on two adjoining spokes near the centre of the top wheel are welds.

Dont know much else about the machine but am interested in others comments on using welded cast wheels. Welding a "non free casting" like a wheel can set up stresses if the whole wheel is not heated before and cooled slowly after welding.

Current owner has been using it for some time without problem but have heard of dogie old bandsaw wheels breaking in use and I find that a scary thought.

Comments or experiences appreciated

Tony

-

28th July 2016 04:28 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

29th July 2016, 10:53 AM #2

I don't know that much about welds, but I would think that a bandsaw wheel is not under a huge amount of stress. Looking at the photo, the welded wheel would be the least of my concerns. I know it's a big bandsaw, but the price seems high for something that's really old (i.e. questionably safety, and probably no parts readily available), rusted all over, obviously repaired (why did it break in the first place), and is being sold in non-working condition without a motor. It may take a lot of time and dollars to get this machine functional again. Unless you really need the huge size, or negotiate a better price, or have a shed full of suitable parts to restore it with, you could get a smaller bandsaw for not too much more that would server you far better as a safe and functional tool for most woodworking.

Good things come to those who wait, and sail right past those who don't reach out and grab them.

-

29th July 2016, 12:06 PM #3

I'm glad someone else said it first....judging by the state of the thing, and the amount of work and money that would need to be put into it, I wouldn't pay anything near $400 for that.

$200 would be nearer the mark, and I'm not sure I'd take it on even at that price.

-

29th July 2016, 02:45 PM #4

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,790

-

29th July 2016, 08:18 PM #5

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2010

- Location

- Port Sorell, Tasmania

- Posts

- 592

Thanks for your replies, They are completely logical and 100% correct. Next question, have you been talking to my wife.

Anyway, curiosity got the better of me and I drove over, with trailer, and had a look at it today. Its an old Macson (as best we could tell in bad light from a painted over name plate). And it is old, with babbit bearings. Everything turns and the bearings have minimal play but the machine would take a fair bit of work to have it looking respectable. It is on a fabricated chassis so it can be moved with a forklift, or pallet trolley. No motor but has mounting bracket on the chassis.

The top wheel has been welded as you can sort of see on gumtree and a closer inspection revealed that the bottom wheel has also been repaired in he same place. two adjoining spokes where they join onto the centre hub of the wheel. This repair was with bronze; presumable from an earlier mishap. The machine appears to have been working for some time with these repairs.

Both wheels appear to be pressed onto the shaft with two circular 1/4 or 5/16 keys. No grub screws etc to secure the wheels.

I didn't buy it but it would be a mate for my old Macson thicknesser. I might have bought it if it were in better condition, none the less an interesting old machine.

Tony

-

29th July 2016, 10:37 PM #6

With these old machines, it depends what you are looking for....

If you are really into machine restoration, love tinkering with bits of metal, tracking down parts, finding the original factory paint colour so you can duplicate it, and generally bringing a machine back to its' former glory - this might be a good project. Alternatively, if you want to just get a half-decent bandsaw and do some woodwork, this isn't the way to go. Two very different things.

-

30th July 2016, 10:17 AM #7

We are in the Antique and Vintage part of the forum aren't we?

If you want to promote Asian rubbish go to the general woodwork area.

My thoughts were that it has survived with blazed repairs as a slow speed metal saw.

The speed and forces generated are way different for wood so forget it as a goer.

Being Macson and babbit means definitely prewar.

The postwar Barkers or Wolfendens would be a better saw if you could find one.

H.Jimcracks for the rich and/or wealthy. (aka GKB '88)

-

30th July 2016, 10:25 AM #8

Oooh...touchy touchy. Pull your head in mate, and maybe engage your brain before posting, eh?

I'm not promoting anything, so stop putting words in my mouth. If you're so keen on this machine, why don't YOU buy it and restore it?

Go back and read the original post - he is looking for a user bandsaw, not something to be done up and looked at.

-

30th July 2016, 12:08 PM #9

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

I didn't reply to this post as the question as I read it, was about welds and the suitability and safety concerns relating to the repair. Admittedly the heading is "bandsaw advice please", but Tony has seemed to have gotten a lot of answers about a lot of questions he hasn't asked, some possibly handy advice, others seem to be coming from not knowing the bandsaw in question and/or having limited experience with restoring machines, but most with a lot of assumptions being made about his intentions and the condition of the bandsaw (that I don't understand how they can be made based only on the photo's and description).

-

30th July 2016, 01:11 PM #10

Have to agree with Camo. what forum are we on here? Band saw are dead simple and you be surprised how dead this older kit has to be to be called a lemon. Braze welds are about the best cast iron welds there are. most likely someone removing the wheels to work the Babbitt broke them with a puller by the looks of it. Wheels just don't brake there on there own. From what little i have seen of that maker its a good one

All tools can be used as hammers

-

30th July 2016, 02:55 PM #11

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2010

- Location

- Port Sorell, Tasmania

- Posts

- 592

I should have been more specific with the title of the thread. The above would be sensible advice to someone who didn't know what they were letting them selves in for.

For me its partly about giving an old machine a new spell of life, they do look fantastic, but it has to be functional. I seem to be racing towards retirement at an unnecessarily rapid rate and have been accumulating timber for that eventuality. I buy logs when I get the chance, have them milled, then rack the timber. As I have generally have no particular project in mind, I have the logs milled into wide 50 mm thick slabs with the idea of breaking them down later. Thus the reason why I think I "need" a large bandsaw, but if it isn't up to the task in mind because of past damage then I'm not interested.

Those of us who are old enough to remember when ABBA were scorching up the charts probably have had a couple of broken bones and carry the odd scar, I know I do, so I wont dismiss a machine an old machine as long as it's still functional (like me).

Tony

-

30th July 2016, 07:43 PM #12

And that's what this bandsaw presented could be, and thats why he is here asking questions on this part of the forum.

This Bandsaw could not only be done up and looking good but I'm pretty sure Tony would be able to cut timber on it as well, and yes looked at too, with a beer in your hand if you like.

I have had a similar 36 inch Bandsaw since I was 24, its a beautiful machine that cuts perfectly and with a wide blade will deep rip as well, as a professional woodworker it has suited my needs and has never let me down.

What's amazing is the lack of vision some members have when it comes to restoring old machines and how they push their limited views on others who either may or may not be interested in undertaking such a restoration task.

Tony, if you were to take this restoration on I would be very "Keen" to help you on your project step by step, and as you will find once finished and running the sense of accomplishment in preserving our industrial heritage far out weighs any joyless unwraping of an imported cardboard box.

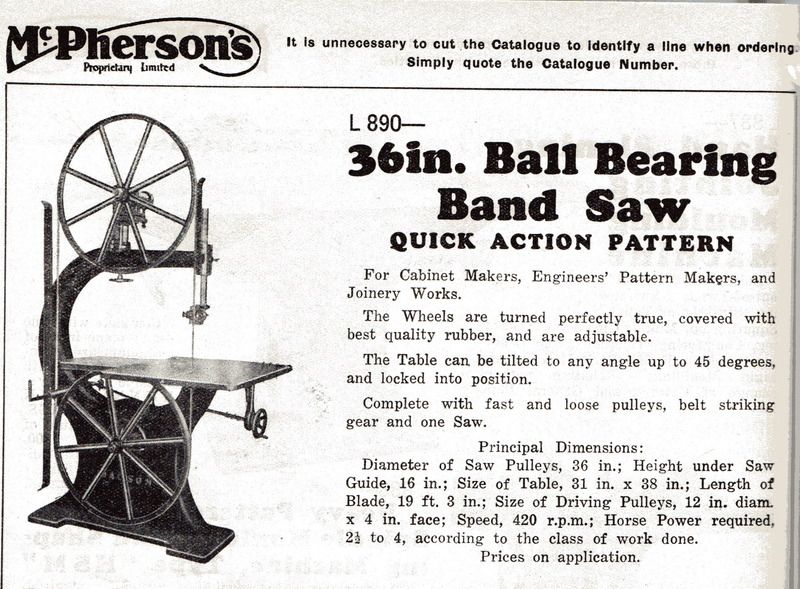

Here is the Ball-bearing version from the 1933 McPhersons catalogue, if it has white metal bearings then its earlier again.

Melbourne Matty.

-

30th July 2016, 08:19 PM #13

If you tap a welded object and it rings , all is good . Is it as good as the day it was made . ?? I don't know, but Id bet on probably not

If any of the welds are still cracked the wheel wont ring , it will have a buzzing sound, you will most defiantly hear it .Its the same as tapping a cracked bit of pottery , fired ceramic . you can hear it .

If it sounded good Id be happy to use it .

$400 and no motor means no one else will buy it . Its a scrap machine, so if the price of cast iron is good , its worth $100 at the most.

I don't think scrap values are to good at the moment so its not worth the scrap guys effort I think .

There's nothing wrong with Babbitt bearings , in fact they are very cool .

Its a bearing type that was superseded because a smaller modern bearing could be put in the same place for a cheaper price, that's why they went by the wayside, they needed more maintenance possibly ? as well , with oiling . Smaller and cheaper took over but did not beat the Babbitt in quality of strength .the Babbitt still exists in new things where those quality's are needed.

If I liked the size of that saw , Id get the guys details and hang around until no one else buys it . And offer what ever you think will take it home .

Rob

-

30th July 2016, 10:01 PM #14

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2010

- Location

- Port Sorell, Tasmania

- Posts

- 592

Thanks for the replies and thanks for the offer Matty. If I need to re do one of the babbitt's I will be looking for advice. I was hoping for some opinions from people who work in the industry and know old machines. As no one is coming out with bad stories Ill take that as a positive. Ill bet this isn't the only machine with welded wheels so presumably you folk would know if there were serious associated problems.

Didn't tap the wheels Rob but did a fair bit of wire brushing and they had a harmonic sound with them. The Ni weld on the top wheel looks particularly neat. The bronze less so but it has likely been operating without problem for many years. I can remember eutectic Ni ? arc welding rods for cast in the late 70's so the bronze work may well predate that.

I could feel a couple of mm movement up and down in the bottom wheel . Wasn't able to see if there were any shims in the bearing housing. Just out of curiosity, at what point do you consider re poring a babbitt?

Tony

-

30th July 2016, 10:22 PM #15

I don't know Tony ? When it's not working any more , or has worn through the Babbitt ?

Lack of oil may be the reason its so worn ? There is some good stuff on you tube about re pouring them .

It doesn't look to hard , Ive never done it though but I have a fair bit of metal working gear, all the stuff to do it so maybe that's why I think its no big deal? Ive one machine with Babbitt . Its running fine last time I used it , So I'm not touching it unless it needs it

When I got this machine going again, the bearings were filthy with rust and crud from sitting outside in the rain . I had the main shaft re made by an engineer and I scrapped the Babbitt clean and as true as I could. I did try bearing blue and putting the shaft in and out and testing , taking a little off here and there . I don't think I got it as good as it was supposed to be , but it worked perfect and I left it at that.

Rob

Rob

Similar Threads

-

Help/Advice 300x300x2500mm wood bench (Metal support advice)

By ryanluo23 in forum WOODWORK - GENERALReplies: 3Last Post: 30th August 2015, 01:36 AM -

Advice ?

By spankingpigeon in forum WOODTURNING - GENERALReplies: 13Last Post: 31st December 2012, 08:14 PM -

need advice desperatly - train trip advice for a smoker!

By Spanner69 in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 11Last Post: 12th June 2010, 03:36 PM -

Need some advice

By emo in forum WOODWORK - GENERALReplies: 3Last Post: 8th June 2010, 01:21 AM -

Need some advice

By lubbing5cherubs in forum WOODTURNING - GENERALReplies: 26Last Post: 8th February 2008, 05:27 AM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote