Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 18

-

10th December 2008, 11:13 PM #1

A 22' Gentleman's Racer begins........

A 22' Gentleman's Racer begins........

Well it's time to put it out there. My new project for 09 is 22' replica Nelson Zimmer runabout.

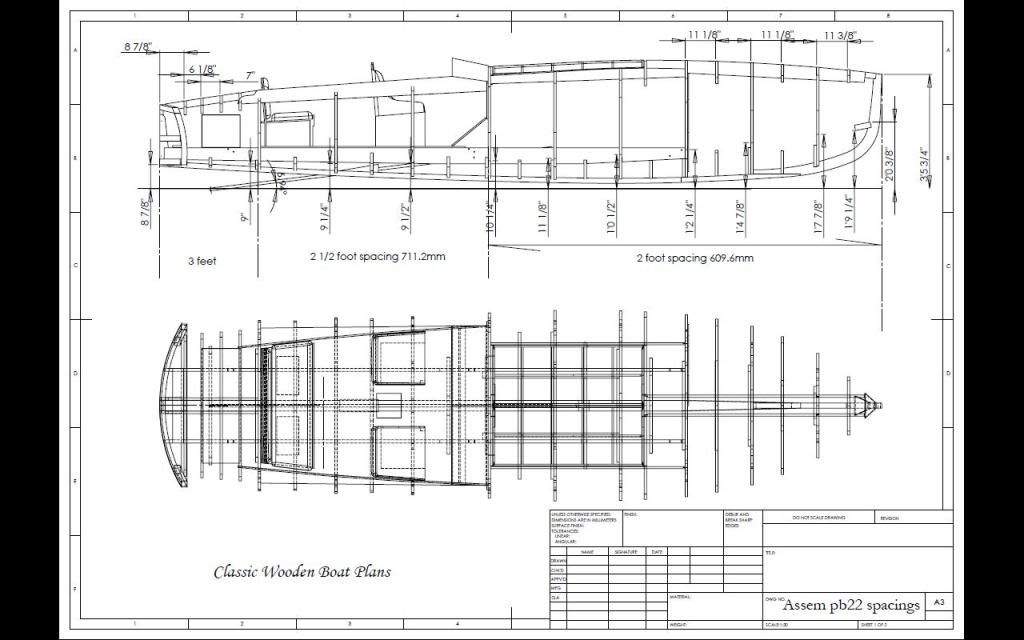

Below is a plan showing spacings etc.

The boat will be a complete replica, as in it will be completely built using lighter and stronger materials. This includes ply ring frames and epoxy stabilisation. There will be no fixings in the frames. The only fixings will be in deck hardwear or accesories as requied. There will be an absolute minimum of accessories as in guages and fancies etc. With a bit of luck in the budget we may even have reverse in there somewhere so long as it pokes out of the floor in an inconvenient place. The exhaust will be musicly and decibely (is that even a word) adequate that MP3 and CD may only be used for the Gold Cup racing numbers that will adorn the sides.

Once the ring fames and ribs are complete and faired, it will be covered in 2 x 4mm ply and faired, ready for the mahogany. The bottom of the hull will be 2x 7mm ply with dynel and filled. Then painted to the water line.

Then the sides will be covered in 7mm mahogany timber, book matched for authenticity and then covered in 3 coats of epoxy. To complete the look there will be 10 - 15 coats of varnish.

The completed boat will have the look of an authentic racer and be finished in Brazilian mahogany. With custom windscreen and deck fittings, it will be similar to this finish.

Any way i wanted to start the thread and open up as much negetive and positive input on the project.

I am starting the project officially on the 5th of Jan 09 so i am slightly ahead of schedule The completion will be the 30th of March 2010.

The completion will be the 30th of March 2010.

Any info that users are willing to input will be valuable towards the completed project if not always appreciated at the time. The feedback offered by more skilled or experienced boat builders will be appreciated as this kind of art needs to be kept alive.

The feedback offered by more skilled or experienced boat builders will be appreciated as this kind of art needs to be kept alive.

There are still many people who appreciate a wooden runabout and the nostalgia they generate in even the youngest of people is proof that they will never trully die .

.

This is the current progress of the boat. Strongback has been constructed and levelled, bolted to the floor and ready for the start of frame construction. First to be fitted will be the engine stringers and aft frames followed by the stem and forward frames. This is the progress as of today.

Stop destroying our planet!...........It's where i keep all my Stuff.

Stop destroying our planet!...........It's where i keep all my Stuff.

Acting my shoe size since 1979

-

10th December 2008 11:13 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

11th December 2008, 06:44 PM #2

Deceased

Deceased

- Join Date

- Dec 2007

- Location

- Guernsey Channel Islands UK

- Age

- 54

- Posts

- 307

she looks nice but where's the sails..lol..

cant wait to see the build progress on this little beauty

-

11th December 2008, 07:26 PM #3

Pricey, that is a project I have often dreamed of.....good luck with it. What are you powering it with?

Rhys

-

11th December 2008, 11:03 PM #4

And you won't find any solar or other electrics either

And you won't find any solar or other electrics either  I must admit i am an old sailor from way back when, but this one will be easier to build than a large sailer.

I must admit i am an old sailor from way back when, but this one will be easier to build than a large sailer.

I would really like to run a Chrysler 360 in her, it will just depend on what's available at the right price at the time. If it's not going to be Chrysler then it will be a 350 Chev Vortech both engines would run around 330-350 HP. Should see her cruise nicely and pull some skiers when the need arises.that is a project I have often dreamed of.....good luck with it. What are you powering it with?

Seems my biggest issue in the short term will be sorting out some suitable and reasonable ply supplies. I would like mahogany ply but getting some that's up to spec is difficult at the moment. I'll track some down after Chrissy.Stop destroying our planet!...........It's where i keep all my Stuff.

Acting my shoe size since 1979

-

12th December 2008, 08:41 AM #5

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Aug 2008

- Location

- Birkdale

- Age

- 51

- Posts

- 279

Pricey,

Firstly, I must say "Holy Sh*t" . That's a nice looking craft.

. That's a nice looking craft. Good luck with the project. You obviously have a lot more patience than me.

Good luck with the project. You obviously have a lot more patience than me.

Cheers,

Chris

-

12th December 2008, 09:14 AM #6

Senior Member

Senior Member

- Join Date

- Nov 2008

- Location

- North Gosford

- Age

- 66

- Posts

- 128

This is going to be fascinating Pricey,

This is going to be fascinating Pricey,

looking forward to the next instalment.

Cheers,

Dave.

-

12th December 2008, 11:52 AM #7

Fantastic project. I will be watching with interest

.

.

-

6th January 2009, 10:32 PM #8

Update on progress

Update on progress

Today i completed the girders for the engine and cut out the first frame. The girders run from just forward of the engine to the transom nearly 5 metres long. These are made out of some beautiful tassie oak. Over the next couple of weeks i'll get the stem and frame six made along with the forward deck stringers. This will allow me to place parts on the strong back and i'll get to see an upside down frame with big gaps in it

. Atleast it will look like to a boat

. Atleast it will look like to a boat  maybe.

Stop destroying our planet!...........It's where i keep all my Stuff.

maybe.

Stop destroying our planet!...........It's where i keep all my Stuff.

Acting my shoe size since 1979

-

7th January 2009, 12:39 PM #9

Plywood ring frames have to be substantially deeper in the molded dimension to replace gusseted sawn or steam bent frames. Who did the frame conversion modifications? How much bigger are they in the molded dimension compared to the originals? It's a very important consideration, especially in light of plywood's physical attributes, compared to solid lumber.

You'll get exceptional performance from this hull form with half of the HP you plan on tossing at her. There's also a "drag wall" you'll encounter around 55 knots (hull form related), where additional power does little but drive the stern deeper and waste fuel, but speed doesn't increase much. Apply more power then this and she'll begin to show signs of instability, plus can trip or swap ends (CG moves too far aft, partly because of bow up attitude), neither of which is enjoyable. These are typical traits of early double wedge type hulls.

This hull type is really best suited at 40 knots as it's maximum, with 30 to 35 knot cruise speeds the norm. 150 HP will get you to the mid and upper 20's, 200 the low to mid 30's and 250 the upper 30's. Much more then this and serious handling issues begin to crop up. This is the very reason no modern hull forms use the early double wedge shapes any more. Without chine flats, lift strakes, stern flare and non-progressively decreasing deadrise aft, the hull has limitations (like all choices in yacht design).

This particular model is an excellent example of the Hacker style of runabout. In their day, they were the fastest of the bunch. Restored originals are worth thick 6 figure sums and I've always thought of these as the class of this model type.

Your other ideas, planking, veneer sheathing, etc., all sound great. It should be a stunning piece once you've completed her.

-

7th January 2009, 11:41 PM #10

Thanks Par for the info. I enjoy input from people who have had experience in this area as i am definately an amateur

From what i understand (which isn't a lot) your comments regarding the power and speed capability are correct. While i was away home visiting family this Christmas i caught up with an old family friend who is also building a similar version called Rosita. He had no idea i was intending building such a craft and i didn't find out until just before i got there he was building 1. Any way after talking to him about the source of power and hull speed capability i will most probably be going for a 305 chev. This will bring the power to around 270 hp. The plans i have are for that horsepower and 50mph max.

After going over the plans from classic wooden boat plans and discussions with several boat builders, i have decided to go with the AS2272 rated F17 Austral Hoop Pine ply. It has a higher rating than BS1088 and cannot be replaced by BS1088. The original plans had a variable frame size from about 1"3/4 at the sheer line too 2"1/2 at the chine. The only gussetting was at the deck which had 1"1/2 across the crown. All frames are 3/4 and some bottom frames are 7/8.

The frames i will be using will be 3/4 or 19mm by a minimum 3" wide. At the sheer and chine i will epoxy on 2x6mm pieces to add structure for the chine and sheer, and energy transfer to the frame around the joints. "Gussetting" is via radius bends in the ply frame itself.

I am confident that this will be sufficient strength wise and is far stronger than original. I would like to build it out of BS1088 mahogany as it is half the cost of the Hoop product. The bottom will be 2x6mm Hoop ply with triaxial glass over the top and the sides will be 2x4mm hoop cold molded where required with 7mm mahogany planking.

This method i also feel gives a strong boat with reduced labour.Stop destroying our planet!...........It's where i keep all my Stuff.

Acting my shoe size since 1979

-

26th January 2009, 07:09 PM #11

Update

Update

All frames, stem and girders are completed. Girders are in place on the strong back and now the frames need to attached to the girders. They are only resting on the girders in the pictures.

Stop destroying our planet!...........It's where i keep all my Stuff.

Stop destroying our planet!...........It's where i keep all my Stuff.

Acting my shoe size since 1979

-

5th March 2009, 08:55 PM #12

Update.................

Update.................

Well just thought i'd post a quick couple of pics of the boat as she is today.

Started on the installation of the chines and had a cube of mahogany delivered.

The chines are 50 x 50 so thaey will be going on in 3 laminations to get the bends required. Even at that size (17 x 50) the hoop is difficult to bend.

I scored a bit of a bargain as well as most of the 8" x 2" are actually 8" x 2 1/2". So i should get 12 x 4" planks from one piece. The planking will be book matched so that means i'll get 6 pairs from the bigger bits versus 4 pairs + 2 unmatched pieces from 2" thickness.

So i should get 12 x 4" planks from one piece. The planking will be book matched so that means i'll get 6 pairs from the bigger bits versus 4 pairs + 2 unmatched pieces from 2" thickness.

The chines and sheer clamps, ribs and the transom should be completed by the end of next w/e 15th. Then i'll get to do some fairing of the hull ready for skinning with ply.

Stop destroying our planet!...........It's where i keep all my Stuff.

of the hull ready for skinning with ply.

Stop destroying our planet!...........It's where i keep all my Stuff.

Acting my shoe size since 1979

-

5th March 2009, 09:28 PM #13

Great progress Pricey- nice to see you have two shop stewards. The timber looks luscious.

-

6th March 2009, 07:49 AM #14

Pricey,

if you are going to re-saw the mahogany yourself on a bandsaw and want to maximise the amount of timber then either use

1. a woodslicer 3/4" blade (0.6mm kerf an really smooth finish) on a smaller saw; or

2. if your saw can take a 1" blade, get a 1" Lennox Woodmaster CT which although is slightly wider in kerf (1.2mm) cuts a bit truer, will last heaps longer and gives an amazing finish - just some sanding required. I would rate this as the best re-saw blade on the market (and we have tried a few believe me!)

Woodslicers from www.highlandhardware.com

Woodmaster from Henry Bros Saws in Sydney.

ADwww.denmanmarine.com.au

Australian agent for Swallow Boats, Bruynzeel Multipanel Plywood and Barton Marine Products

-

6th March 2009, 09:54 PM #15

Stop destroying our planet!...........It's where i keep all my Stuff.

Stop destroying our planet!...........It's where i keep all my Stuff.

Acting my shoe size since 1979

Similar Threads

-

another Yellowtail begins

By honkongphoie in forum BOAT BUILDING / REPAIRINGReplies: 88Last Post: 30th June 2009, 09:19 AM -

And So It Begins...

By funkychicken in forum A Woodies YarnReplies: 294Last Post: 5th May 2008, 11:34 AM -

The Spiers Saga Begins!

By Auld Bassoon in forum HAND TOOLS - POWEREDReplies: 46Last Post: 27th July 2006, 08:58 PM -

Another box begins

By GRS in forum WOODWORK PICSReplies: 4Last Post: 15th November 2005, 08:42 AM

Reply With Quote

Reply With Quote