Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 16

Thread: My 7x12 Mini lathe...first item

-

10th June 2009, 04:33 PM #1

My 7x12 Mini lathe...first item

My 7x12 Mini lathe...first item

Finally got around too having a go on my mini lathe which has been sitting there for 6 months.

Heres my first item, works way better than I imagined.

[ame="http://www.youtube.com/watch?v=FZOA1zTI-fA"]YouTube - HPI 5B Baja axle dog bone dust boot installation[/ame]I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

Albert Einstein

-

10th June 2009 04:33 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

10th June 2009, 05:36 PM #2

Senior Member

Senior Member

- Join Date

- May 2009

- Location

- SW Sydney

- Posts

- 112

Looks pretty good for your first try and I know how much it sucks turning long tapers on a 7x12

Did you use a 4 jaw chuck or is the block simply bolted on? My biggest gripe is the small through hole in the spindle and the even smaller hole in my chuck.

-

10th June 2009, 06:00 PM #3

-

10th June 2009, 06:27 PM #4

Senior Member

Senior Member

- Join Date

- May 2009

- Location

- SW Sydney

- Posts

- 112

Its impossible to fit anything bigger than 22mm through the headstock, 18.5mm in my chuck (3/4" is a tight tight fit)

It makes turning anything bigger than 3/4" next to impossible for me when the object is longer than a few inches. I was offered a job of making some 1lb rocket tooling (3/4") and had to turn it down as It was impossible (without spending $100+ on a new chuck) to face and drill out the long rammers. I'll probably end up selling my mini lathe and getting something bigger, only cost me $250 (ebay bargain eh)

-

10th June 2009, 07:42 PM #5

i know its something for a car right?

looks goodhappy turning

Patrick

-

10th June 2009, 07:54 PM #6

-

19th June 2009, 06:01 PM #7

[ame="http://www.youtube.com/watch?v=BBZ3jbJT1-U"]YouTube - mini lathe on aluminium[/ame]

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

Albert Einstein

-

28th June 2009, 03:15 PM #8

Nice video Martrix

Don't want to come across as a "safety nazi", but I cringed every time that hand with the glove went to the spinning lathe .

.

Was polishing some brass rifle cartridges the other day and didn't want to get black fingers, so used some very tight fitting surgical gloves, still managed to get gloves caught, just as well they stretched!!!

Generally not recommended to wear gloves around spinning machinery

-

28th June 2009, 03:55 PM #9

yep fair point and well understood. That hand was generally always a good 7" - 8" away from the chuck at all times. I had to wear the tip-less gloves that day because it was dead cold, so I proceeded with extra caution and took a risk. The old 400watt motor is not overly powerful anyway, but point taken. Not to mention also that my feet were absolutely frozen cold from standing still on a cold concrete slab for hours on end. I'm definitely going to get some of that thick rubber flooring stuff.I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

Albert Einstein

-

28th June 2009, 04:05 PM #10

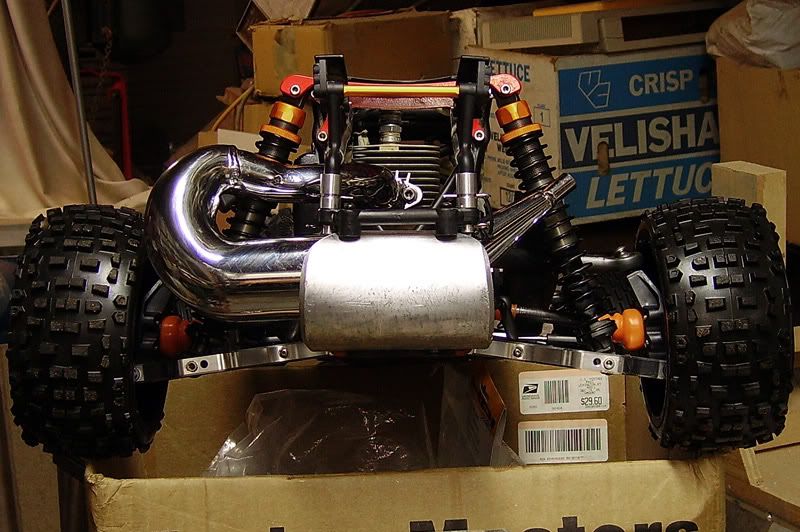

I forgot to post the pics of what I was making in that vid, here they are. They lift the roll cage up 1/2" to clear the hot exhaust pipe.

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

Albert Einstein

-

28th June 2009, 04:22 PM #11

-

29th September 2009, 08:50 PM #12

latest off the mini lathe. I had a bit of problems with chatter on these ones, mainly I think because its a little harder? than other brass Ive turned? plus I was chucking the piece from the internal diameter because I didn't realise the lathe came withe bigger jaws which you can use which would've enabled me to hold the outside of the piece....lol, newbie.

The outside dia. is about 55mm. Also was my first crack at turning mild steel using HSS cutter. Works well with a little cutting oil brushed on before each pass.

The items are holding sleeves for my MIG torch, of which I will post later.

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

Albert Einstein

-

15th November 2009, 12:18 PM #13

Latest off the mini. This was to solve the old "odd" size dust outlets for some power tools. Normally I would stick the vac pipe on and wrap masking tape around it to hold it there, pain in the ass.

So Ive turned up these adapters to suit with a 2.5° taper push-on fit. I think next time 1° taper would be better. Spun out of Acetal or 'Delrin', awesome stuff to turn, so easy.

Had a play with throwing some grooves on it for looks and to add a little extra grip to them. Need to grind up a tool specifically for this as I used my parting tool on a 45°.

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

Albert Einstein

-

15th November 2009, 12:43 PM #14

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,795

-

15th November 2009, 01:18 PM #15

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

Albert Einstein

Similar Threads

-

Mini Lathe

By LiliB in forum WOODTURNING - GENERALReplies: 19Last Post: 29th November 2008, 03:43 PM -

Mini Mini lathe

By wheelinround in forum WOODTURNING - GENERALReplies: 5Last Post: 13th August 2008, 11:01 PM -

Which Mini Lathe?

By CLEVE in forum WOODTURNING - GENERALReplies: 1Last Post: 15th June 2006, 05:35 PM -

Mini Lathe

By Bodgy in forum METALWORK FORUMReplies: 6Last Post: 6th August 2005, 11:50 PM

Grab yourself a lathe, they are so friccin handy, Ill be getting a bigger one for sure when the space permits.

Grab yourself a lathe, they are so friccin handy, Ill be getting a bigger one for sure when the space permits.