Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 181 to 195 of 196

Thread: All hail the shaper gods!!

-

22nd June 2012, 01:50 AM #181

Clean up the broken bits so i could braze some more cast in. They are at the end of the table but of course it just occurred to me i could lock the clapper and use the tool backwards

. There are several sections on the middle of the table though and i would think using the shaper to cut pockets for new cast would be a bit hard....i think....

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

. There are several sections on the middle of the table though and i would think using the shaper to cut pockets for new cast would be a bit hard....i think....

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

22nd June 2012 01:50 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

22nd June 2012, 09:31 AM #182

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

-

26th June 2012, 08:08 PM #183

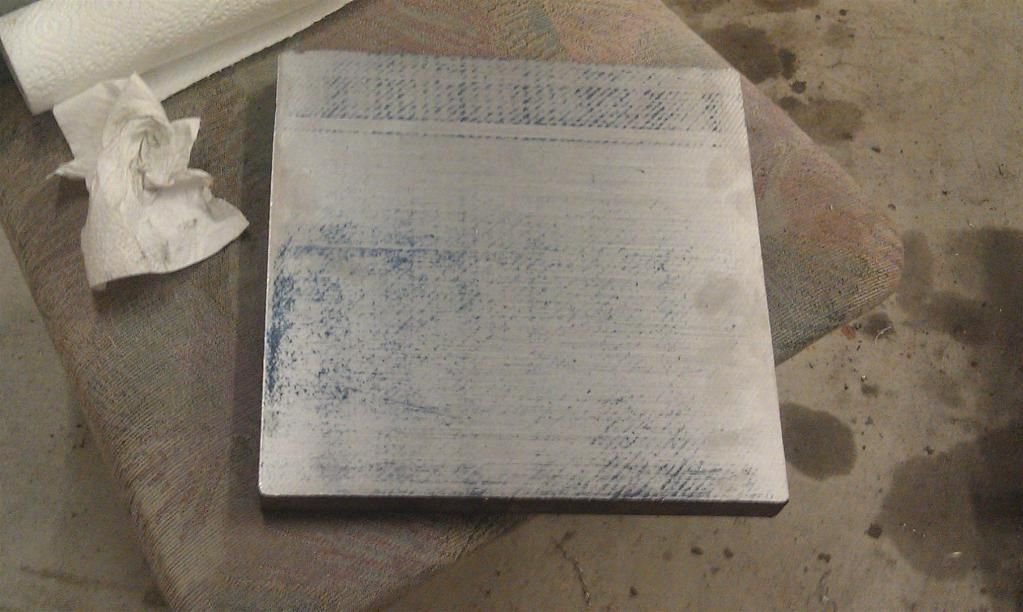

As i had the blue out today i thought i would spot the 11" square plate on the granite to see how flat she is cutting. The cut is of a shear tool but i think i can get a better finish, i just need to get the cutter right. Oddly enough the far side of the plate was cut yesterday, the rest was finished today

Here is a quick vid of the shear tool doing its thing. Thia was MK1 ground as to the1944 books spec, only 15 deg angle. I have since ground it to 45 with better results, but still not as good as i would like. The stroke is long in an attempt to get a higher surface speed and stop the tool from striking the work from the "clap" that comes with the change in ram direction.

[ame=http://www.youtube.com/watch?v=GHFZTJkx_jU]24" Queen City shaper shear tool - YouTube[/ame]1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

28th June 2012, 12:33 PM #184

GOLD MEMBER

GOLD MEMBER

- Join Date

- Aug 2011

- Location

- Melbourne

- Posts

- 2,951

These shapers have me interested. I think it may have to be my next machine tool purchase. I'm still learning about all things about turning and milling and I know even less about using shapers. One thing that they all seem to have in common (other than the obvious) is that they all look like pure brutes of machines. Are they made so massive because there are huge cutting forces involved in such a machining technique?

They also seem relatively cheaper than their mill and lathe counterparts. Is that because they are inherently simple in design?

Ewan, that finish looks OK! I assume it's possible to get similar surface finish qualities that that of a surface grinder?

Cheers

Simon

-

28th June 2012, 01:42 PM #185

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Hi Ewan,

You're upset at the flatness of that piece? If you cut off "yesterdays" part it would likely look better. Yesterdays work is lifting toadys work off the plate.

You need a tool lifter

Stuart

-

28th June 2012, 02:06 PM #186

Philomath in training

Philomath in training

- Join Date

- Oct 2011

- Location

- Adelaide

- Age

- 59

- Posts

- 3,149

Simon,

Shapers are cheaper because usually industry has no use for them these days. Milling a flat surface is faster than using a shaper, so that's the weapon of choice. Mills are also considered more versatile as well (although as plenty here will tell you, shapers can do some interesting stuff too).

From memory, historically shapers were important as they were the tool in the industrial revolution that enabled the economic production of flat surfaces that then gave rise to all the other metal machines that were necessary.

Part of the mass would be historic, part due to cutting forces, some would be that castings are harder to make with thin walls (and cast iron is (relatively) cheap).

Michael

-

28th June 2012, 02:39 PM #187

GOLD MEMBER

GOLD MEMBER

- Join Date

- Aug 2011

- Location

- Melbourne

- Posts

- 2,951

-

30th June 2012, 11:14 PM #188

Novice

Novice

- Join Date

- Jun 2012

- Location

- Rye,Vic, Australia

- Posts

- 19

Heads UP

Heads UP

Spotted this thread the other night and thought what a cool machine, then spotted this one tonight so thought I would give you a heads up.

Description:

-

1st July 2012, 12:16 AM #189

Nice shader! I haven't got one of those yet.....

-

1st July 2012, 01:15 AM #190

I'm just trying to work out how it works.....it must have a special pencil holder at the front and you put paper on the table......

Could be a nice little machine for someone in VIC. Has a feed ratchet on the knee rise and fall shaft. Interesting table support.....but no vice. Should be in the Ebay thread though, maybe a mod could copy it there?1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

7th July 2012, 07:05 PM #191

Hi,

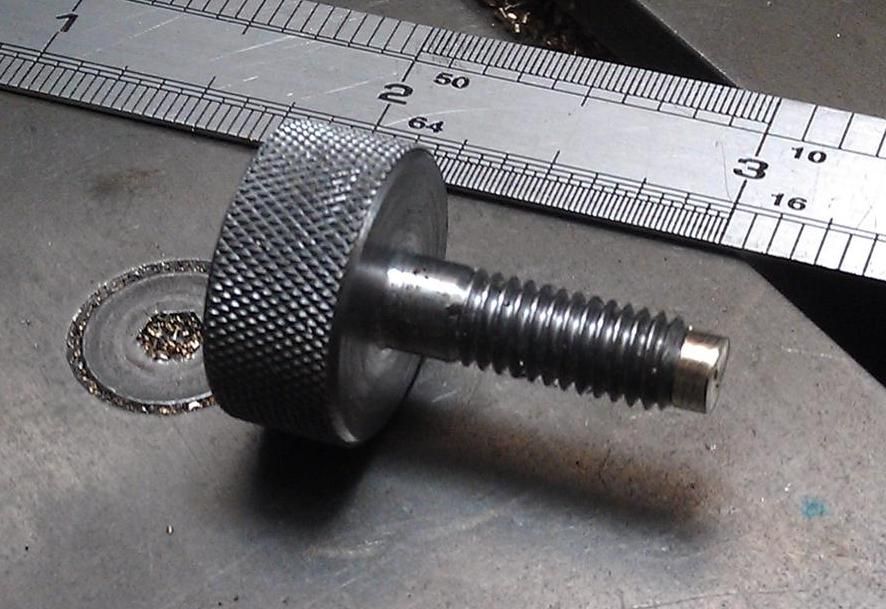

After i made the BIG chips this arvo it was clear i needed to make a proper knurled thumbscrew for the head collar so i went to town. I decided to put a brass tip on it, i just bored the end of the screw 1/8" and turned a piece of 1/4" brass rod to fit with a boss on the end. My first knurl turned double so i filed it off and went again.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

11th August 2012, 07:33 PM #192

I've finally gotten to sorting out the table support bolts. I bought some 5/8 UNF grade 8.8 bolts a week or 2 ago and got to sorting out the washers etc over the week. I just need to make a washer/ bolt head holder for the inside of the support and then cast some knobs (ping pong balls on standby

)

)

As luck had it the handles off the mill are the same thread as what i went with so it gave me a chance to see what it would look like. The nuts are 2" dia x 1 1/4" thick, blind threaded and the washers are 3/8" thick. Beefy enough?

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

11th August 2012, 07:51 PM #193

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

-

11th August 2012, 08:14 PM #194

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 2,659

Very nice Ewan.

-

16th August 2012, 12:40 PM #195

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2008

- Location

- N.W.Tasmania

- Posts

- 703

G'Day Gentlemen, Here is a link recently uploaded by Mr.Pete, AKA Tubal Cain, who has lots of interesting videos on youtube as most of you will be aware. Here he shows off a recent gift. Much smaller than yours Ewan, but a real gem non-the-less

Rob

antique model METAL SHAPER MODEL (like ATLAS) tubalcain - YouTubeLast edited by DavidG; 17th October 2012 at 05:57 PM.

Similar Threads

-

Gippsland, Gods own country one day, pretentious the next!

By AussieOzBorn in forum WOODWORKERS WITH DISABILITIESReplies: 8Last Post: 12th September 2012, 01:26 AM -

Hail storm

By PenTurner in forum WOODTURNING - PEN TURNINGReplies: 8Last Post: 10th March 2010, 03:49 AM -

just had some hail

By underfoot in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 5Last Post: 24th October 2008, 02:41 AM -

HAIL TRITONEERS

By DPB in forum TRITON / GMCReplies: 23Last Post: 12th December 2002, 05:41 PM