Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 30 of 189

Thread: Show us your lathe

-

1st August 2010, 03:29 AM #16

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Mar 2010

- Location

- Nth Qld

- Posts

- 715

It's a basic quick dry white enamel base from Altex Coatings, with lots of phthalocyanine blue tint added. The finish is really an orange peel finish up close as I sprayed it on thick (little thinner) to avoid runs in the paint. By not having a two pack I should be able to touch it up from time to time. Also the camera shows it as being lighter than than it actually is.

If anyone is going to strip old pink oil soaked cast iron bog that they all seem to be filled with, then I recommend using a decent size angle grinder fitted with the correct rpm wire cup wheel to rip it out. This beat out all other methods like paint stripper for speed.

-

1st August 2010 03:29 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

1st August 2010, 11:52 AM #17

Novice

Novice

- Join Date

- Feb 2010

- Location

- Newtown, Sydney

- Posts

- 15

G'day all,

this year I moved into a house with a shed, after spending the last 10 years living in flats and at sea. It is like heaven having your own creative space, as I am sure you guys would agree.

Here is a pic of the lathe I purchased recently which I am really pleased with, it's an AL-960B, which I believe a few users on this forum have.

I have also included a pic of the bench I built and my mill, which is a nice bit of kit too....

-

1st August 2010, 12:02 PM #18

AuusieJoe ,

I spent a couple of years using a Macson lathe the same vintage as yours ,during my apprenticeship .

It a was slightly larger model with a longer bed .

They are a great lathe ,very solid and the one I used was very accurate.

The tapered scroll three jaw chuck fitted to them is the strongest three jaw chuck on the planet ,designed by Taylor in the UK .

I have a 4" Taylor tapered scroll chuck that came with the Myford.

The taperdTaylor chucks were very expensive in thier day and the outside clamping jaws were an optional extra , a lot of buyers didn't opt for the extra jaws because of the extra expense ,so the optional jaws are very hard to find these days.

My Edgewick lathe has an 8" Tapered Taylor chuck fitted but unfortunately no outside jaws.

The local Tafe had a Macson the same model as I used to operate ,

when it closed the lathe was sold , but I think some one already had tabs on it and it was sold with out any advertising .I know who has it and will be visiting his workshop shortly to have a look at it.

Kev."Outside of a dog a book is man's best friend ,inside a dog it's too dark to read"

Groucho Marx

-

1st August 2010, 12:37 PM #19

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2006

- Location

- Adelaide

- Posts

- 2,680

I'm Jealous .,.,...AGAIN!!!

(one day I might win lotto...be able to pay swmbo what she wants and then maybe still have enough left over to get something decent....so for the moment the..err my lathe can still stay where it is ...i dont want to get yelled at...not until I know she is very very very happy....lol)

-

1st August 2010, 03:23 PM #20

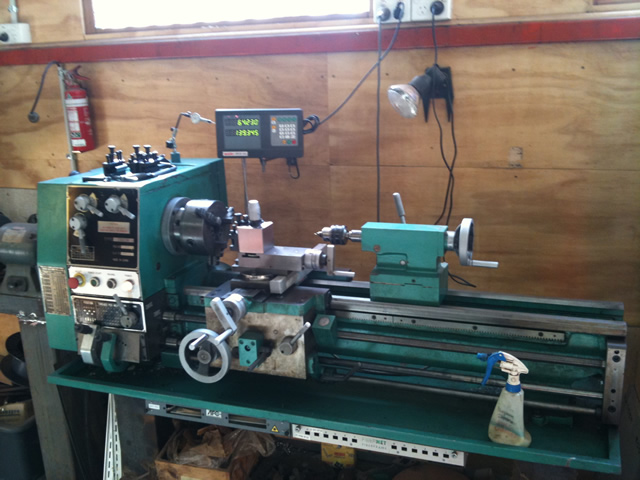

Strictly speaking, this isn't actually my lathe, it belongs to my next door neighbour (who is now a long term hospital patient after a heart attack left him in pretty bad shape)

I have added the DRO and QCTP both of which have made a big difference in terms of ease of use, I mostly seem to use insert tooling.

There are a couple of shallow drawers underneath for tool storage. They are from some fibre optic patch panels.

It's badged CQ6230, made in December 1993, I have had to make a new gear selector lever after the cast one broke and jammed the gear box.

The only other issue I have had is the electric motor bearings needed replacing.

The DRO is a Meister, (from ebay), which I'm pretty happy with, I don't have DRO on the compound slide (like Dave's) , which would be a nice thing to have sometimes.

My next lathe will probably be an AL960B... which I very nearly bought after the gear box crash on this one earlier this year.

Regards

Ray

-

1st August 2010, 04:43 PM #21

Member

Member

- Join Date

- Aug 2008

- Location

- Brisbane

- Age

- 74

- Posts

- 58

This is my AL960B bought new from H&F 18 years ago (when they were in Woolloongabba, for old Brisbanites). The dial guage set up is the best gadget I've ever made. I can now do precision work like interference fits and bearing shafts and housings with confidence. QC toolpost I made from a design in Australian Model Engineer (AME). Other pics are a clutch setup - also from an article in AME some years ago. This is also an improvement I love.

Graham

-

1st August 2010, 04:44 PM #22Dave J Guest

Hi Ray,

I see you have the same tool post as mine from H&F. I would like to find the factory in china or Taiwan were they make these to buy them in bulk. I have looked up the name (Fmco) a few time but cant find anything.

To get my miester cross slide scale sitting lower I removed the oil cap on the saddle and put in a large grub screw with plumbers tape on it in the hole instead.

My vice was bought in about 82 and is made by Joplin in Sydney, not sure if there still going but it has had some abuse over the years and is still going strong.

Dave

-

1st August 2010, 06:30 PM #23

Hi Dave,

I've tried as well to find an alternate supplier for the L295 holder to suit the QA-150 QCTP, I did find a very similar looking one made by http://www.jihshun.com.tw

Without getting detailed specs, it's a bit of a gamble as to whether they will fit.

This is the picture from their web site, that I've been looking at.

http://www.jihshun.com.tw/pd-gif/AS/...ool%20post.JPG

The picture is from this page, scroll down a bit to the accessories.

http://www.jihshun.com.tw/English/p2-5B-e.htm

I'd be interested in a bulk purchase if the price was right.

Regards

Ray

-

1st August 2010, 06:50 PM #24Dave J Guest

They could be a possibility for getting them bulk. I might sent an email for a picture of the specs to compare them to ours.

Another mod I did to mine was to make a new tool post nut. It's a hex head cap nut to suit the height adjustment spanner, so only one spanner is needed to adjust the height or turn the tool post. I did use the original handle first off, but found it got in the way sometimes. With having it set up this way I can leave it on or take it off.

Dave

-

2nd August 2010, 01:43 PM #25

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Aug 2008

- Location

- Charlestown NSW

- Age

- 65

- Posts

- 899

DustInOz

I see you are building a model steam loco. I wonder why so many Mariners build model steam loco's. I've either known or know of, quite few over the years who have/are building steam locos.

Big job, better men than me. LOL

bollie7

-

2nd August 2010, 02:26 PM #26

Mechanical Butcher

Mechanical Butcher

- Join Date

- Oct 2004

- Location

- Southern Highlands NSW

- Posts

- 920

That's a pattern of a Dickson toolpost, made in England.

I have 2 of these, a genuine and an Indian made copy. The real Dickson I can't fault, but the Indian did have a little problem. When using the parting tool, it broke. Amazingly, not the parting blade, but the toolholder, at the T slots that get gripped by the plunger on the toolpost. I think it must be glass-hard. Bit of a lucky dip, these pattern parts!

Jordan

-

2nd August 2010, 03:06 PM #27Dave J Guest

Graham

Interesting setup with the clutch, do you have a few more details and picture. Also is the bracket arrangement between the 2 pulleys to hold the belt when it is slack?

Jordan

That looks like cast? There was no way I buy a real Dickson at there price.

Quality is one thing I cant complain about the H&F tool post, they are a quality copy of the Dickson, made of hardened steel and and precision ground. The tool holders are the same which makes me think they might be Taiwanese made.

I buy a bit of Indian stuff at the local market off the Indian fellows, and most stuff is not well made. I have noticed even they are now starting to sell Chinese gear.

Dave

Edit

Here are a few pictures of the Hare and Forbes tool post and holders.

The only problem with the H&F one is, the holders are $76 each theres nothing wrong with the quality.

theres nothing wrong with the quality.

I will make sure I ask the manufactures when getting quotes, what there tool holders are made of after seeing your tool holder.

If I cant find them at a reasonable price I will have to make them on the shaper, but I want about 20-30 holders so thats a bit of work.

One bloke did a nice right up, he's name is Dave as well so don't mistake him with me.

I have been caught out with that before after giving the link on another forum.

Dave WorkShop

-

2nd August 2010, 03:54 PM #28

Mechanical Butcher

Mechanical Butcher

- Join Date

- Oct 2004

- Location

- Southern Highlands NSW

- Posts

- 920

I'm pretty sure it's steel, just too hard. They should be tempered after hardening, I think? Then they might not shatter like this. Trouble is, it looked nicely made, and I only found out about the brittleness in use. Good reports (and bad!) are useful to share - nice to hear a positive about the H&F one.

I was lucky the original Dickson toolpost I have came with a lathe I bought.

Jordan

-

2nd August 2010, 04:35 PM #29

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

And then there's this design by John Stevenson, if anyone's keen to make their own: Quick Change Toolpost

-

2nd August 2010, 05:08 PM #30Dave J Guest

There are a lot of different designs out there, Retromilling from this forum built one a while back, that came up nice.

The link I gave above was to making a Dickson style tool holder.

On Daves site he has a lot of useful info for people starting out, and has done some mods with his smaller lathes and mill, worth looking at if you own one. He has a few links to other sites of interest as well. One is to ISHIMURA Japanese site Mini Lathe Workshop

Dave

Similar Threads

-

Volunteer to show how good the Forums are at Sydney TWWW Show.

By jmk89 in forum ANNOUNCEMENTSReplies: 19Last Post: 16th June 2010, 06:43 PM -

Price needed at the Show - VL 100 lathe

By jefferson in forum WOODTURNING - GENERALReplies: 14Last Post: 26th October 2008, 06:45 PM -

UK Woodworkers Show, Kempton park. Show report.

By docusk in forum WOODWORK - GENERALReplies: 3Last Post: 22nd November 2006, 07:10 AM -

Sydney Wood Show Vs Canberra Show

By I_wanna_Shed in forum WOODWORK - GENERALReplies: 8Last Post: 10th April 2006, 06:16 PM -

New Teknatool Lathe on show

By ubeaut in forum WOODTURNING - GENERALReplies: 7Last Post: 25th April 2002, 07:00 PM

Likes:

Likes: