Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 189

Thread: Show us your lathe

-

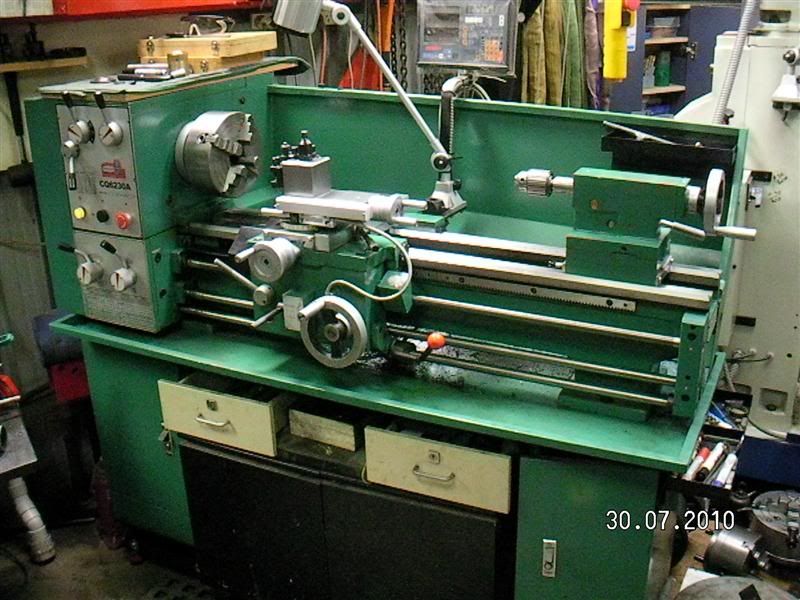

30th July 2010, 08:49 PM #1Dave J Guest

Show us your lathe

Show us your lathe

Hi Guys,

Here is a thread for members to show off there lathes. Come on it's time to dust off all those monarch's etc and take a picture. lol

I was thinking about what Gavin said about his mill in the "show us your mill thread"

If members put up a picture of their lathe and mill, when anybody is asking for advice to do something, we all know what type of equipment they have and can give advice based on the machines capability's.

Anyway here is 1 of mine, a Toolex (Gasweld) 12 x 36. I have had it for about 6 trouble free years , and after owning a Hercus for 15 years it was a big step up.

I have added 3 axis dro, quick change tool post, way covers, way wipers, carriage lock handle etc.

The Chinese always sell these machines to suit their height, so I added 100mm channel around the bottom of the cabinets and adjustable feet to bring it up an extra 150mm from standard height.

A few months back I mounted a 250mm chuck to my face plate for larger jobs, I think I might be getting close to steping up to something like RC's lathe.

I will take a picture of my Ward turret lathe latter and post it up as well.

Dave

-

30th July 2010 08:49 PM # ADSGoogle Adsense Advertisement

-

30th July 2010, 09:44 PM #2

Intermediate Member

Intermediate Member

- Join Date

- Jun 2010

- Location

- Melbourne

- Posts

- 41

This is my 16 speed localy made Macson. It replaced my small Colchester master. Fantastic machine to work with and I only have a couple of small things to 'reco' and she will be as good as new. The wife calls this thing the 'stargate' as it sounds like the item from the t.v show when I flick her on.

Oh, and the little Hercus that I have some serious plans for........

Last edited by aussiejoeblow; 30th July 2010 at 09:57 PM. Reason: Forgot to add content.

-

30th July 2010, 10:40 PM #3

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

-

30th July 2010, 10:43 PM #4Dave J Guest

RC

Whats the other big lathe in the back ground of picture 1?

Dave

-

30th July 2010, 11:01 PM #5

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

You posted too fast Dave, that is the New Visby...I edited it in...

-

30th July 2010, 11:14 PM #6

Here s my little Myford Super 7 .

It has a 5" 3 jaw chuck fitted ,two face plates , a catch plate , universal milling attachment and vice , Myford dividing attachment and a full set of Myford collets and chuck.

There are also a 4 Myford four jaw , Myford 3 jaw and a couple of other smaller chucks for it including a Myford specific ER32 collet chuck.

I mainly use Er 32 collets ,which I also use in my mill.

The other pic is of my Edgewick toolroom lathe which is due for a total restoration in the future.

Kev."Outside of a dog a book is man's best friend ,inside a dog it's too dark to read"

Groucho Marx

-

30th July 2010, 11:33 PM #7

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Mar 2010

- Location

- Nth Qld

- Posts

- 715

Hahaha, I was talking to a guy who worked in a local shipyard where an old co-worker used a Macson. No-one else could get anywhere near as good work from this Macson and the other machinists were amazed at how he could get any work at all form the lathe.

My friend noticed this old guy used to adjust a bolt on the headstock and throw the spanner in the sump. Turns out this guy was loosening the spindle bush whenever he wasn't using it and tightening it back up for his work.

This is my 1953 Graziano SAG180 (only 14" unlike RC's) which has had every bearing replaced and adjustments made. Unlike later models this machine runs a bit faster than later models at 1800 rpm and has a high pressure bronze bush fluid bearing instead of the later model's Gamet bearings at $5K-7K for a set if you can find them (Phew!). It also has the oil filled Collotti clutches to let you stick it in reverse at full speed in less than a second when high speed threading. It has lapped chrome steel forged gears and flame hardened ways and to my mind it has the styling of a world war two fighter plane with the louvre vents on the belt and motor cover.

-

31st July 2010, 02:30 AM #8

-

31st July 2010, 02:43 AM #9Dave J Guest

You guys have some nice lathes

Matthew,

I see your running full flood cooling, any problems with rust so far? I have it on the mill but am thinking of hooking mine up on the lathe.

Dave

-

31st July 2010, 10:17 AM #10

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Mar 2010

- Location

- Nth Qld

- Posts

- 715

-

31st July 2010, 10:38 AM #11

Dave,

I run full cooling systems on two of my lathes and both mills, As well as my bandsaw and

power hacksaw..I use the AIS brand of water soluble oil at a mix of 17 to 1.

I have been running this mix in all machines and if anything it prevents rust on the

ways..

Well it seems to me that where ever the coolant goes there is no sighn whatsoever

of any form of corrosion.

Hope this helps.Warning Disclaimer

-

31st July 2010, 02:45 PM #12

Here is my AL960B (one of many we blokes seem to have bought recently - we should have asked for bulk discount from H&F

)

)

Attachment 143296

I haven't done many modifications as it seems to fine out of the box. The first thing I changed (as I did on the AL320G I had before) was to replace the plastic handles with aluminium & brass ones. It just feels nicer in use. At the right you can see the tee-bar replacement for the saddle clamp - much quicker than using an allen key under the compound each time.

Attachment 143297

Another small annoyance on the 960 is that the compound is clamped by socket head cap screws which fill up with swarf. A short length of 5mm hex pressed into a bit of 1/2" round solves that problem.

Attachment 143298

I don't like using soluble coolant so most of my work is done dry. If I need oil/coolant I have a gravity feed system using an old JAP fuel tank.

Attachment 143299

I was disappointed by the quality (loose term) of the commercially available knurlers so, as with most other people, I made my own - I think it's beefy enough! The arms pivot at the very rear so they are supported from sideways movement by the tool side.

Attachment 143300

And lastly, my mill/drill. It's too wimpy to post in the mill thread but for $200 delivered to my workshop I can't complain. It's Taiwanese and has a replacement 3Hp Australian made motor. One day I'll get a proper mill when the domestic goddess loosens the purse strings but for now it does fine.

Attachment 143301Last edited by Gavin Newman; 31st July 2010 at 02:46 PM. Reason: Sorry about the sideways piccy's, I'll get the hang of this one day.

-

31st July 2010, 06:33 PM #13

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Here's mine. Its the same as a H&F AL-335 just a little longer between centers. The biggest mods so far are an hour meter(why? because I had one in my shed) and the foot "brake". Its just a switch at the minute but I may add a brake at a later date. My theory on emergency stops is, if you don't use it every time you wont remember to use it when you need it.

Next picture is the vertical slide bracket I made

The last is a rough spindle I set up to fix a cracked pulley on my compressor.

-

31st July 2010, 08:55 PM #14

Intermediate Member

Intermediate Member

- Join Date

- Jun 2010

- Location

- Melbourne

- Posts

- 41

Graziano......very nice paint job

-

31st July 2010, 08:57 PM #15

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

Similar Threads

-

Volunteer to show how good the Forums are at Sydney TWWW Show.

By jmk89 in forum ANNOUNCEMENTSReplies: 19Last Post: 16th June 2010, 06:43 PM -

Price needed at the Show - VL 100 lathe

By jefferson in forum WOODTURNING - GENERALReplies: 14Last Post: 26th October 2008, 06:45 PM -

UK Woodworkers Show, Kempton park. Show report.

By docusk in forum WOODWORK - GENERALReplies: 3Last Post: 22nd November 2006, 07:10 AM -

Sydney Wood Show Vs Canberra Show

By I_wanna_Shed in forum WOODWORK - GENERALReplies: 8Last Post: 10th April 2006, 06:16 PM -

New Teknatool Lathe on show

By ubeaut in forum WOODTURNING - GENERALReplies: 7Last Post: 25th April 2002, 07:00 PM

Likes:

Likes: