Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 18 of 18

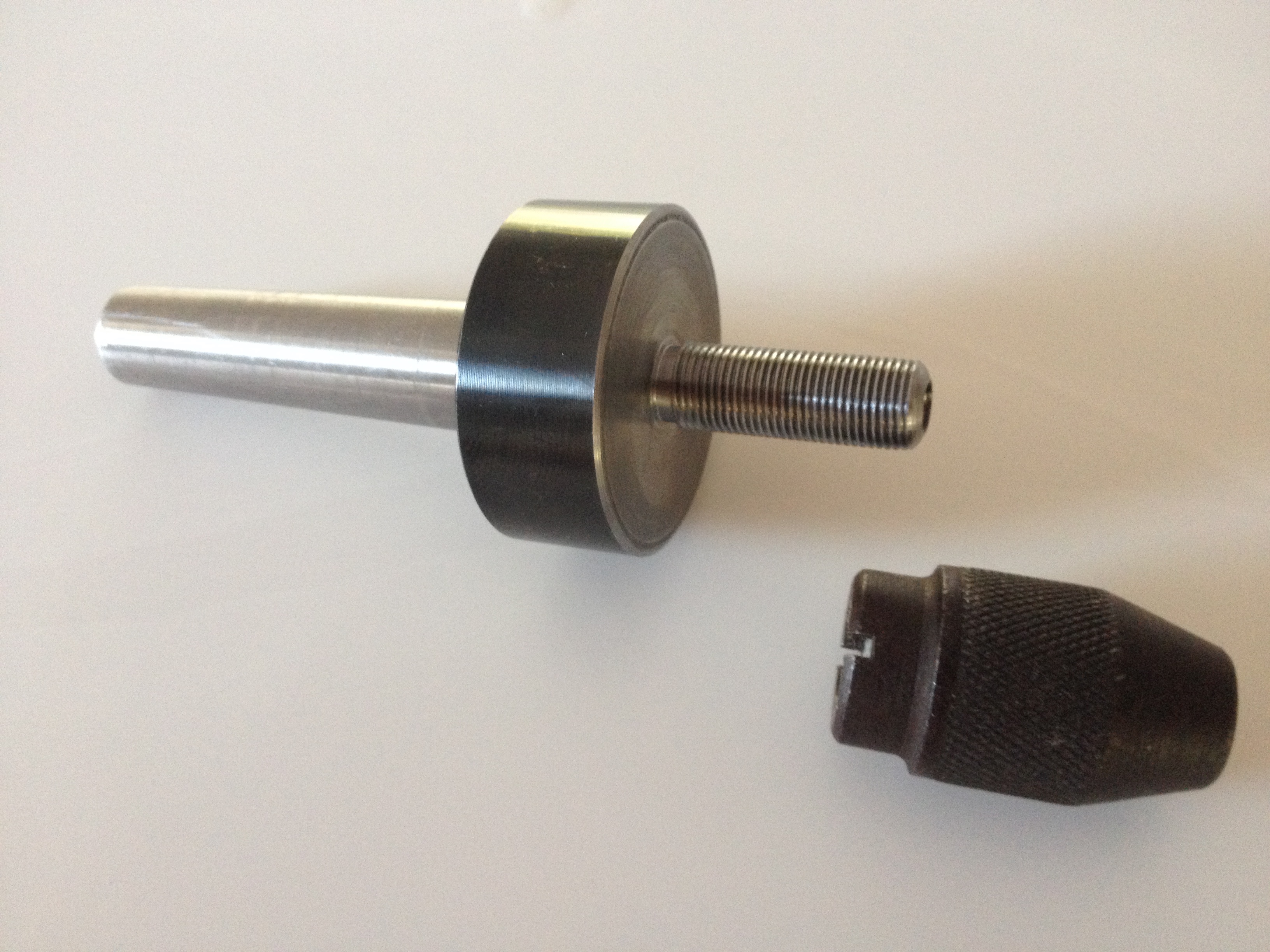

Thread: MT2 Pin-Chuck holder advice

-

30th November 2014, 01:13 AM #16

-

30th November 2014 01:13 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

30th November 2014, 04:37 PM #17

Cba

Cba

- Join Date

- Aug 2007

- Location

- Melbourne

- Age

- 68

- Posts

- 1,417

Looks like your MT2 has no tang. It is likely tapped for a drawbar? If so, what I do is to insert a grub screw instead of a drawbar. Adust the grubscrew until it just ejects from your tailstock, measure how much it protrudes. Then remove grubscrew, add a low strength (removable) threadlock (like Loctite) and readjust grubscrew to the measured protrusion plus about one mm. The one mm will allow for many years of wear before you need to readjust the grubscrew.

-

10th January 2015, 10:32 PM #18

Quick update, I used my new chuck again the other day and decided I would tap the end for an M5 thread and then screwed an M5 Cap Head all the way in. Problem solved. It's the perfect length and my rule on the Tailstock reads zero's correctly.

Thx

Jon

Similar Threads

-

Chuck advice

By floody_85 in forum WOODTURNING - GENERALReplies: 18Last Post: 6th November 2012, 02:26 PM -

Chuck advice...

By Yonnee in forum WOODTURNING - GENERALReplies: 11Last Post: 18th June 2012, 10:48 PM -

Metal Lathe tool holder advice

By wjcoll in forum METALWORK FORUMReplies: 33Last Post: 1st March 2012, 03:42 PM -

Chuck key holder

By IanW in forum HAND TOOLS - POWEREDReplies: 15Last Post: 7th April 2011, 02:05 PM -

ER11 Collet Chuck Holder

By triden in forum CNC MachinesReplies: 5Last Post: 21st November 2010, 12:14 PM

Thanks:

Thanks:  Likes:

Likes: