Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 14 of 14

-

5th October 2009, 01:49 PM #1

Offset needed for cam in a 3 jaw chuck

Offset needed for cam in a 3 jaw chuck

Is there a formula that calculates the amount of packing needed so that you can turn a cam using a 3 jaw chuck? For example, if I had a 1 inch round bar and I wanted to turn a 5/8 inch cam what size packing would I use on one of the jaws?

-

5th October 2009 01:49 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

5th October 2009, 04:26 PM #2

Senior Member

Senior Member

- Join Date

- Apr 2008

- Location

- NSW

- Posts

- 356

This site might help but I can't explain the math as I am no good at math.

Chapter 6. Cams

You could set up and just scribe a very slight cut on the end of the bar after facing it first , that would prove the profile of the offset. Then repack and test cut again untill you get it right. Try 1/8 packing to start.The volume of a pizza of thickness 'a' and radius 'z' is given by pi z z a.

-

5th October 2009, 04:52 PM #3

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,796

That website is way more complicated than what I think Tiger needs.

One thing that site shows is there are may different cam types. I assume Tiger requires just a simple circle that is offset from the original stock centre?

If so, the amount of packing not only depends on the size of the starting stock and size of the cam, but what offset position from the centre of the 1" stock you want for your cam.

A cam made in this way can can be offset from 0 to a maximum of

half the diameter of the stock Minus half the diameter of the cam

1/2 - 5/16 = 8/16 - 5/16 = 3/16

So you could have a 5/8 cam located just off zero to up to 3/16 out from the centre. If you go further than this you wont get a round cam.

Here's a simple figure showing schematically 1 concentric radius and 3 offset circles each nominally offset by 1/16" - I think this is what he is after?

The amount of offset should thus equal the amount of packing. But I agree with Retro, try packing and approach the expose end of the stock and see what it turns.

-

5th October 2009, 05:33 PM #4

Senior Member

Senior Member

- Join Date

- Apr 2008

- Location

- NSW

- Posts

- 356

After a bit of head scratching I think to get a cam with a 5/8 lift I think you are going to need 1 1/8 stock . 5/8 above the center 3/8 below and 1/8 to turn off to create the cam shape. That's 9/8 . I am just working it out bush style so I may be wrong.

The volume of a pizza of thickness 'a' and radius 'z' is given by pi z z a.

-

5th October 2009, 06:14 PM #5

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,796

-

5th October 2009, 06:32 PM #6

Senior Member

Senior Member

- Join Date

- Apr 2008

- Location

- NSW

- Posts

- 356

Thanks Bob thats sounds right to me . I did not think a one inch bar was big enough.

The volume of a pizza of thickness 'a' and radius 'z' is given by pi z z a.

-

5th October 2009, 06:36 PM #7

Senior Member

Senior Member

- Join Date

- Mar 2007

- Location

- Canberra

- Age

- 68

- Posts

- 181

Have a look on this page for ECCENT.ZIP. I thinks it's what you are looking for. Lots of other good stuff on this site.

Peter

-

5th October 2009, 11:05 PM #8

Senior Member

Senior Member

- Join Date

- Apr 2008

- Location

- NSW

- Posts

- 356

I found this info on a US site. Don't know how accurate it is but you can test it.

When I think about it the three jaws work together and close at the same rate in the three directions so this info could well be right.

"

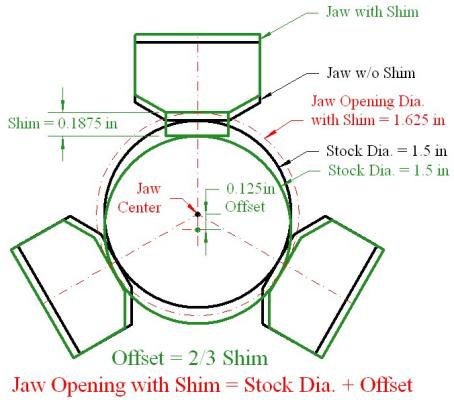

comment by Dick Kostelnicek- HMSC MemberUpon reading about Joe Williams' offset turning technique, I wanted to know if I could determine the shim thickness directly from the desired offset. So, I did the math and came up with the formula: OFFSET = 2/3 SHIM THICKNESS. An example is shown in the diagram at the right. Incidentally, putting the same thickness shims on two of the jaws gives the same offset as a single shimmed jaw.

comment by Dick Kostelnicek- HMSC MemberUpon reading about Joe Williams' offset turning technique, I wanted to know if I could determine the shim thickness directly from the desired offset. So, I did the math and came up with the formula: OFFSET = 2/3 SHIM THICKNESS. An example is shown in the diagram at the right. Incidentally, putting the same thickness shims on two of the jaws gives the same offset as a single shimmed jaw.

This formula is good for both hex and round stock as long as the round stock does not shift so far that it falls off the edge of a jaw's flat. Hex stock is more forgiving. Its flats, effectively, extend the contact with the flats on the jaws so it can take a larger offset than round stock of the same diameter. Although I haven't tried it, round stock less than 1-1/8-in. dia. could be held in a 5C hex collet block and offset with a shim against the block.

The new jaw opening for a given offset is given by the formula:JAW OPENING = STOCK DIAMETER + OFFSET. In the case of hex stock, use across-the-flats as the stock diameter.

Joe measured his shim thickness as 0.055 in., which calls for an offset of 2/3 x 0.055 = 0.036. His measured offset was 0.033-in.The volume of a pizza of thickness 'a' and radius 'z' is given by pi z z a.

-

5th October 2009, 11:21 PM #9

Senior Member

Senior Member

- Join Date

- Apr 2008

- Location

- NSW

- Posts

- 356

I downloaded the small dos based program that wannabe linked to and it works but only after right clicking and opening properties on the EXE program and selecting the program tab , then unchecking the "close on exit box".

This then places a shortcut in the same folder. However you don't use the shortcut but just leave it therr in the folder . Then just open the EXE file and it calculated a shim thickness for a certain offset and material size.

I don't know why it does that maybe its a win XP thing .

Extract the files to the one folder and see how you go if it just shuts down before giving you the shim thickness answer then do what I said above.

After running the program with bar thickness of 1.25 and an offsett of .25 it came up with .3750 shim thickness .

That agrees with the other info above . The offsett is = to 2/3 of the shim thickness.

.3750 -;- 3 x 2 = .250

Now I have to go and take a headache tablet because I have strained my brain with my limited math capability.The volume of a pizza of thickness 'a' and radius 'z' is given by pi z z a.

-

5th October 2009, 11:34 PM #10

Senior Member

Senior Member

- Join Date

- Mar 2007

- Location

- Canberra

- Age

- 68

- Posts

- 181

Sorry. I should have explained how to run the thing. All his software is DOS based but as from Win XP DOS was considered unimportant and they set it up to work that way. Why I don't know. Don't you love Microsoft.

Anyway once you get that figured out the software is clunky but it serves the purpose and is very useful. The one for creating flywheel spokes is very good too.Peter

-

5th October 2009, 11:46 PM #11

Senior Member

Senior Member

- Join Date

- Apr 2008

- Location

- NSW

- Posts

- 356

Yes there is some useful stuff . I use the taper and sinebar programs with my top slide taper gauge. I did not know that it had this eccentic program also .

Trouble is we still need to know the required offset for a certain lift cam. Maybe he is going to have to draw it out and take an offsett from the drawing.The volume of a pizza of thickness 'a' and radius 'z' is given by pi z z a.

-

6th October 2009, 10:29 AM #12

Senior Member

Senior Member

- Join Date

- Mar 2007

- Location

- Canberra

- Age

- 68

- Posts

- 181

There's another program there called CAM.ZIP. I haven't looked at it but it may be of some use.

Peter

-

6th October 2009, 03:22 PM #13

Thanks Retro, Wannabe and Bob.

I like the 2/3 thickness rule and that will probably do me but it's nice to have the program that calcuates exact thicknesses.

-

8th October 2009, 04:28 PM #14

Senior Member

Senior Member

- Join Date

- Apr 2008

- Location

- NSW

- Posts

- 356

Similar Threads

-

anyone seen these offset hinges in Australia???

By womble in forum WOODWORK - GENERALReplies: 3Last Post: 4th December 2008, 07:57 AM -

Offset Bowl

By Fredo in forum WOODTURNING - GENERALReplies: 16Last Post: 13th August 2008, 09:18 PM -

CS Offset plate

By niki in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 0Last Post: 10th March 2007, 07:36 PM -

Offset turning

By macca2 in forum WOODTURNING - GENERALReplies: 5Last Post: 4th July 2004, 11:08 PM