Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 631 to 645 of 1571

Thread: Your latest project

-

7th January 2013, 11:26 PM #631Dave J Guest

Harty, great job.

I looked through your photos earlier and it was definitely a labour of love, many many hours spent on that boat but it has come out looking new or better.

Dave

-

7th January 2013 11:26 PM # ADSGoogle Adsense Advertisement

-

7th January 2013, 11:42 PM #632

Nice one Ueee! Folded in situ from the looks. Very neat too.

I really have to clean up my shed very soon. I'm envious of your clean floor..... Cheers,

Cheers,

Joe

9"thicknesser/planer, 12" bench saw, 2Hp Dusty, 5/8" Drill press, 10" Makita drop saw, 2Hp Makita outer, the usual power tools and carpentry hand tools...

-

7th January 2013, 11:46 PM #633

Senior Member

Senior Member

- Join Date

- Oct 2008

- Location

- Wimmera

- Age

- 51

- Posts

- 363

Thanks Dave and others

I would not call the paint stripping a labor of love especially when you dont wash your hand properly and you go for a leak. what you cant feel burn on your hand you defiantly can on your landing gear

the rest of it was good fun

now i just need to name her

cheers

Harty

-

8th January 2013, 01:01 AM #634Dave J Guest

What about Hartys toil

Verb

Work extremely hard or incessantly. Noun

Exhausting physical labor: "a life of toil".

Dave

-

13th January 2013, 01:00 PM #635

Senior Member

Senior Member

- Join Date

- Jun 2007

- Location

- Vic

- Age

- 48

- Posts

- 200

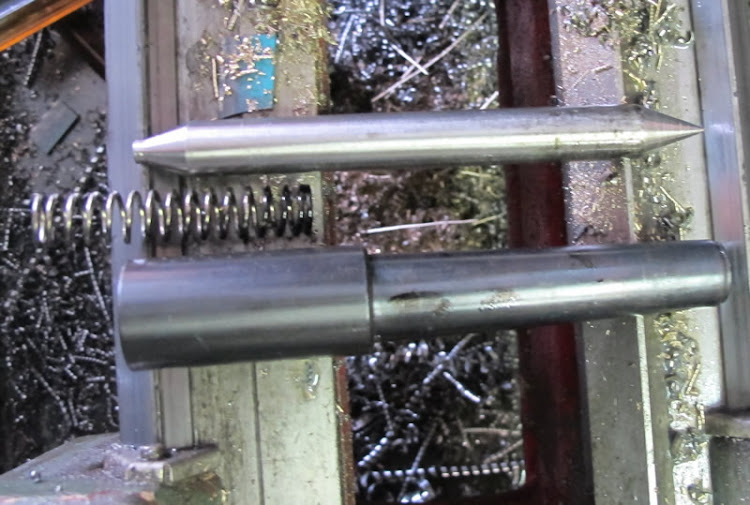

Nothing special, I am still on holidays and managed to make a few things

and a toolpost for my hercus

-

13th January 2013, 03:13 PM #636

Home Hobbist

Home Hobbist

- Join Date

- Aug 2008

- Location

- Oatley NSW

- Age

- 69

- Posts

- 244

Built A New Workbench

Built A New Workbench

Hi All,

I found that I needed a new Workbench so gave it some thought so it could serve several purposes.

Decided that it needed to have clamping points for welding and jiging but at other times just needed to be just a bench so this is what I came up with.

50mm Angle Iron for the main outer top, 50mm Square for Legs and Uprights, 40mm Angle Iron for Inner Frame, a Shelf below the Inner Frame with a Gal Sheet for any Welding Slag and used Form Ply for Removable Top Board and fixed Bottom Shelf.

Pictures attached so you can see what I did.

-

14th January 2013, 02:19 PM #637

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2012

- Location

- Australia

- Posts

- 765

HI Jason,

Looking good, last time I saw your keypad it was still being milled, it came out very spiffy. Ray Just pointed me to here as i have been looking at reduction gearing systems for a proposal I'm working on. Nice work on the HypoCycloidal drive, I'll like to see it in motion. Anyway I came across a reduction gearing that I thought was interesting enough to post: HarmomicDrive and they say that it is possible for a 330:1 reduction in a single stage which i thought was pretty impressive.

-Josh

-

14th January 2013, 02:27 PM #638

Senior Member

Senior Member

- Join Date

- Oct 2008

- Location

- Wimmera

- Age

- 51

- Posts

- 363

Hi Josh

thats the gearbox that is in the wrist on the fanuc m1 robots which is what i made the 4th axis for the mill from. it took me a while to workout how it all worked once i pulled it apart

the best part of this system is no backlash bloody brilliant idea

cheers

Harty

-

14th January 2013, 02:45 PM #639

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2012

- Location

- Australia

- Posts

- 765

I agree so simple, but so effective. I had never seen one, I'm more familiar with planetary reduction. How is it for noise at full speed? (one of my concerns), I would think that the gearing would be relatively quite compared to even a helical planetary since there is only two mesh points?

-Josh

-

14th January 2013, 03:33 PM #640

Senior Member

Senior Member

- Join Date

- Oct 2008

- Location

- Wimmera

- Age

- 51

- Posts

- 363

Hi Josh

its running on a stepper so its not high rpm but its still very quiet

cheers

Harty

-

14th January 2013, 04:22 PM #641

GOLD MEMBER

GOLD MEMBER

- Join Date

- Oct 2010

- Location

- melbourne, laverton

- Posts

- 1,469

hurcus upgrades

hurcus upgrades

hi mate i made a tool post very similar. how many tool holders did you make? some of mine a made with 3 bolt holes for holding down the cutting tool but found 4 better. have you made much other things for your hurces , a great lathe.

from simons camera 019.jpgfrom simons camera 013.jpg

-

14th January 2013, 10:17 PM #642

Hi Harty,

I've just spent a pleasant hour looking through the all pictures of the rebuild, I was expecting to be impressed with the attention to detail and thorough planning, and wasn't disappointed. I can remember a picture of the boat in another thread a while back ( I think it was a 40+ degree day ) and you'd been out in the heat scraping paint...

Nice to see all that blood and sweat come to a great conclusion.. here's to those many happy years of fishing ahead!

Regards

Ray

-

14th January 2013, 10:23 PM #643

Senior Member

Senior Member

- Join Date

- Oct 2008

- Location

- Wimmera

- Age

- 51

- Posts

- 363

Hi Ray

Thanks for the kind words

I may have done too good a job though cos now the wife wants to come fishing too

cheers

Harty

-

16th January 2013, 09:09 AM #644

Lucky you did not paint it red, because you would have more then the wife wanting to be seen on board.

vapourforge.com

vapourforge.com

-

16th January 2013, 08:20 PM #645

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

Latest project has been this new room in the shed extension.... Fully enclosed 32 square metres.... Going to use it for doing things that I would like to stay fairly dust free..... Already got the surface plate spot earmarked in it..

Light red, the colour of choice for the discerning man.

Similar Threads

-

latest little project

By wayno60 in forum WELDINGReplies: 3Last Post: 12th July 2008, 03:40 PM -

My Latest Project

By cypher in forum WOODTURNING - GENERALReplies: 7Last Post: 26th June 2006, 05:22 PM -

my latest project

By sedaps in forum WOODWORK PICSReplies: 4Last Post: 12th July 2005, 12:05 PM -

Latest project

By Different in forum WOODWORK PICSReplies: 14Last Post: 12th July 2005, 11:15 AM

Thanks:

Thanks:  Likes:

Likes: