Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 31 to 45 of 59

Thread: Shaper Tooling

-

10th January 2012, 11:35 PM #31

Hi Stuart,

Video uploaded, then came up with an error... so I'm uploading again. But what I didn't notice until I watched the video again, is that the bounce happens when it hits a chip on the return path.. never spotted it while running..

never spotted it while running..

Regards

Ray

-

10th January 2012 11:35 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

10th January 2012, 11:51 PM #32

Bump!... video finally worked.

-

10th January 2012, 11:57 PM #33

They also have much wider jaws for more work piece jaw contact .

Kev"Outside of a dog a book is man's best friend ,inside a dog it's too dark to read"

Groucho Marx

-

11th January 2012, 05:45 AM #34

Novice

Novice

- Join Date

- Dec 2011

- Location

- Ashburton

- Posts

- 20

I feel so inadequate....

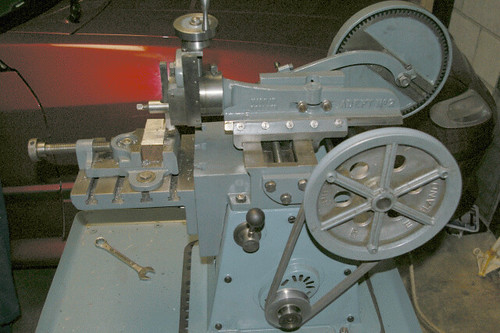

... my little Adept power shaper is so petite I can pick it up and carry it around the shop, but she is so cute and is the only machine in my shop with a name, "Sally Shaper"

It came with a nice little vice which is just like a drill press vice except there is a bolt that pulls the moving jaw firmly down, of course it is the last thing to be tightened. I presume one might be able to modify a bigger drill press vice to get something like the same if pressed. However the little vice eventually broke, due to a horrible inclusion in the casting (pommy, not asian!), it has been repaired but is not a big as it used to be! The point is that without the vice I had to begin clamping to the table and found that in many cases this is actually better than using a vice.

I made a couple of stops that fit in the T-slots, they just drop in and are not fixed in any way, then a simple clamp holds the work down and I have never had a piece come loose. One advantage of the stops is that they give an edge at right angles to the shaper stroke.

Yes, yes, I know I will need to post pictures! .

.

-

11th January 2012, 06:41 AM #35

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 2,659

HI Ray,

Sorry for not writing sooner but my support group had a meeting last night . First up, welcome to the curly swarf makers club. You are gunna have such fun. Secondly, I studied your video and your tool is actually skipping on the return stroke. This is most likely caused by the counterbalanced weight close to the pivot point. Moving the cutting edge close or even behind the pivot point will cause a counterbalanced situation which takes the weight off the tool. Try to imagine if your tool was about a foot back. This theory of the tool being further in the aft position was more for the spring neck holders. As an exercise, turn your holder around and and take some cuts. A helpful hint and one I always use is to file a small bevel or chamfer on the lead in edge on the work to stop any nasty marks at the beginning of the cut.

. First up, welcome to the curly swarf makers club. You are gunna have such fun. Secondly, I studied your video and your tool is actually skipping on the return stroke. This is most likely caused by the counterbalanced weight close to the pivot point. Moving the cutting edge close or even behind the pivot point will cause a counterbalanced situation which takes the weight off the tool. Try to imagine if your tool was about a foot back. This theory of the tool being further in the aft position was more for the spring neck holders. As an exercise, turn your holder around and and take some cuts. A helpful hint and one I always use is to file a small bevel or chamfer on the lead in edge on the work to stop any nasty marks at the beginning of the cut.

Yet again you have blown me away with your thoroughness and attention to detail

I have given up going to the support group and instead will be staying home and having fun using my shaper.

That and the fact I need therapy on so many levels, and all machining related...go figure

Great work Ray.

Phil

-

11th January 2012, 09:45 AM #36

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Hi Ray,

You have to hate that! Nice video though.

I cant recall if you have a metal bandsaw? I guess you've seen the power hacksaw shaper mods?

Hi John,

Why would that be? I think I'm right in saying you're the only guy here with a traveling head shaper. Interesting machine.

Stuart

-

11th January 2012, 10:06 AM #37

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2011

- Location

- Dural NSW

- Age

- 82

- Posts

- 1,120

Shaper & Support Groups

Shaper & Support Groups

Phil

I just viewed the video, & kick myself for selling off a Douglas Shaper some years back.

Shapers are great machine tools. I will be on the search for a decent machine.

Please provide location of any Support Group for this malady of the "curly chip" thinking & other dysfunctions I have.

I live out of NW Sydney in the bush at Dural, room in the workshop for more machines & tools.

regards

Bruce

-

11th January 2012, 10:11 AM #38

Thanks Phil,

I think I've been hypnotized... swish click, swish click, swish click...

Thanks for the tip, I'll swap the tool back to the normal way and see how it goes, I've got a few tools to grind yet and plan to have a go at slotting, and a shear tool.. sign me up for the next support group meeting...

Hi Stuart,

I've been thinking of the hacksaw modification, I don't have a bandsaw, so a hacksaw frame might be an ideal little project. The add on grinder idea is something i've been mulling over.

Don't feel inadequate John, size isn't everything... portable is always a big plus..

Regards

Ray

-

11th January 2012, 10:18 AM #39

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

Hi Ray. Looking good. I would run that cut a fair bit faster though. Don't know if you've seen the attached table. I tend to go slower than they say, but still faster than your vid.

-

11th January 2012, 10:26 AM #40

Thanks Bryan,

I was looking for a good speed chart, The machine is in a sort of an intermediate test mode at the moment, I haven't wired it up properly, the motor is 2.2 kW, still wired in star... running off a 1.5 kW VFD at 30 Hz, and the gear box was the slowest ratio..

When I get the proper VFD, and do the wiring properly, I'll rewire it for delta and crank up to 50 Hz, but while I'm feeling my way with the machine, I feel happier at the slow speed.

Regards

Ray

-

11th January 2012, 10:32 AM #41

Mechanical Butcher

Mechanical Butcher

- Join Date

- Oct 2004

- Location

- Southern Highlands NSW

- Posts

- 920

-

11th January 2012, 11:06 AM #42

Novice

Novice

- Join Date

- Dec 2011

- Location

- Ashburton

- Posts

- 20

That is a nice machine Jordan, the quality of those knobs and the patina!

Have your looked at lathes.co.uk ? He has a few shapers on there too and that rack type handle gear is kind of familiar.

My Adept shaper is a factory adaptation of a hand shaper, you can see two bolts on the ram next to a slot where the handle would go though on the manual version.

-

11th January 2012, 08:58 PM #43

More mucking about with shaper tooling, had a go at a shear finishing tool. Nice curls, I think Bryan calls them "Shirley Temples" .. good name

[ame=http://www.youtube.com/watch?v=CBTDdP95BO4]Varnamo Shaper Test Shearing Tool - YouTube[/ame]

I tried reversing the holder, and will keep experimenting.. Speed is now cranked up to a blindingly fast 40Hz... still low gear though..

Regards

Ray

-

11th January 2012, 09:22 PM #44

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

Ray you've got that shear tool working very nicely. Couple of comments. I wouldn't normally cut that deep with it. The edge I find quite fragile, so I remove stock with a roughing tool and keep my finishing cuts to around .1mm or less. Often .05 is enough to remove tooling marks. And I think you're feeding the wrong way. I know opinions differ on this. Try it both ways and see which you prefer.

-

11th January 2012, 09:42 PM #45

Hi Bryan,

You mean feed left to right? instead of right to left... ok I'll see how it goes, and I'll lighten off on the cut.

Regards

Ray

Similar Threads

-

Al's tooling up!!

By Sigidi in forum SMALL TIMBER MILLINGReplies: 44Last Post: 7th October 2011, 10:12 PM -

CTC Tooling

By krisfarm in forum METALWORK FORUMReplies: 9Last Post: 27th March 2010, 10:53 PM -

Lathe Tooling

By glock40sw in forum METALWORK FORUMReplies: 10Last Post: 13th August 2007, 08:39 AM -

Need tooling for mill

By antoni in forum METALWORK FORUMReplies: 3Last Post: 29th July 2007, 10:11 PM -

HSS/carbide tooling

By metaboman in forum METALWORK FORUMReplies: 1Last Post: 11th April 2007, 05:04 PM