Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 46 to 59 of 59

Thread: Shaper Tooling

-

11th January 2012, 10:23 PM #46

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 2,659

Hi Bruce,

could you imagine what would happen if we started our own support group. It would just be a room full of shapers running and cutting nothing. Everyone sitting around in a circle just looking at them with blank stares.

Hi Ray,

I think for the angle of your tool you are feeding ok but like Bryan says its a personal preference kind of thing. I always prefer the leading portion to do the bulk of the cutting and the trailing to do the cleaning up.(even I don't understand what I just wrote)

Try straightening the clapper box and tool to keep the lot vertically in line.

Phil

-

11th January 2012 10:23 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

11th January 2012, 10:49 PM #47

Hi Phil,

I just straightened the tool holder and reversed the cutter, (so it's in front of the clapper), and increased the speed and then ran light cuts ( less than 0.1) both ways traversing left-right and right-left, I think the one where it pushes the chips away from the finished surface was a little better, but there's not a lot in it.

I've made the edge straight, when viewed end on, some I've looked at show a slight curve, should it be slightly curved when viewed from end on?

Save a seat for me in the circle... I've got the blank stare pretty much down pat..

I've got the blank stare pretty much down pat..

Regards

Ray

-

11th January 2012, 11:05 PM #48

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

Ray, the way I like is with the chip rolling onto the uncut side. I think Phil means the opposite. Suit yourself. I don't think it matters about the curve. Just depends on your preferred grinding technique. A pretty wide range of angles works there. I do think a little rake helps though. Above the edge that is.

-

11th January 2012, 11:16 PM #49

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 2,659

Hi ray

I haven't tried it curved on that face. Theory says it would be better but theory and practice are normally worlds apart. You could say I always keep a straight face

-

11th January 2012, 11:24 PM #50

-

12th January 2012, 09:23 AM #51

Mechanical Butcher

Mechanical Butcher

- Join Date

- Oct 2004

- Location

- Southern Highlands NSW

- Posts

- 920

-

24th January 2012, 03:19 PM #52

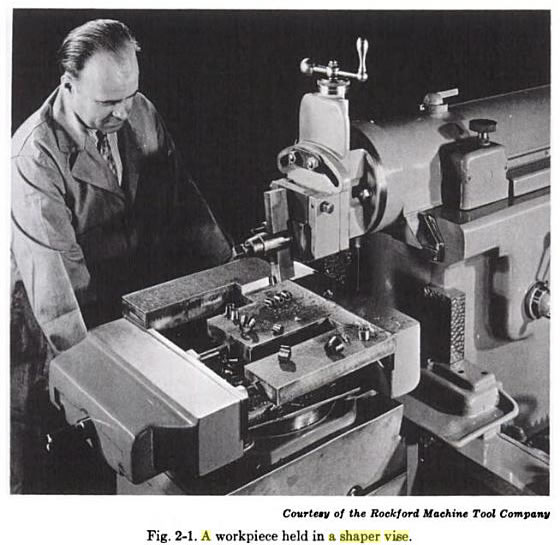

The shaper vise quest continues...

Are there any guidelines for sizing a shaper vise?

I'm looking for a 12" shaper vise, but one guy I talked to says, what do you need one that big for? That size is too heavy and cumbersome. Mind you, he was trying to sell me a smaller milling vise...

So for an 18" shaper, what size vise would most likely have originally come with the machine?

Regards

Ray

-

24th January 2012, 04:03 PM #53Dave J Guest

Kev said to me about half the stroke, but I like a little bigger so I think the 12 would be good. It all depends on what your doing really as something small could be held in a 5 inch vise.

Dave

-

24th January 2012, 07:00 PM #54

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

Ray, my shaper is also an 18". I don't know what vise it had originally, but the one I found (actually Stuart found) is I think 9" across the jaws. It's an Elliot one, the same as Stuart's. I've found it to be a good fit for the machine. The mount holes happen to suit my table. I usually slide it onto a trolley but I can lift it if I have to; any bigger and that would be out.

I guess my advice would be grab anything that suits your table slots and is between say 8" - 12". Even a smaller one might be worth having as it would be easy to sell on if you found a bigger one later. To be honest I suspect that a solid mill vise would be perfectly adequate, as long as you kept your cuts moderate. I'm guessing shaper vises were designed back when shapers where the workhorses of mass production and were pushed to the limit.

-

24th January 2012, 07:14 PM #55

Thanks Bryan, Dave,

How about one of these? I reckon the size looks about right...

Regards

Ray

-

24th January 2012, 07:17 PM #56Dave J Guest

Might be a bit small for yours Ray, LOL

I think shapers come out with the largest vises for there size, than any other machine.

Dave

-

24th January 2012, 10:40 PM #57

What Ive read in some of the old shaper books , general rule of thumb is the jaw width is 50% of the stroke length .

So for an 18" shaper a 9" jaw with would be right .

The Elliot shaper vices have slotted holes on the corners of the mounting plates so they could fit most of thier machines.

From an old MacPherson catalogue page I have ,which has a picture of a shaper identical to the 18" stroke Alba I have ,gives a description of the vice as being 9 1/4 " jaw width with a 10" opening capacity and a jaw depth of 2 3/8 " .

Picked up an Armstrong tool holder off EbayUS last week ,its the T-2-S ,takes a 3/8" sq tool and has no back rake in the holder at all. $32.00AUD including postage.

Kev."Outside of a dog a book is man's best friend ,inside a dog it's too dark to read"

Groucho Marx

-

24th January 2012, 10:51 PM #58

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

-

24th January 2012, 10:56 PM #59Dave J Guest

Similar Threads

-

Al's tooling up!!

By Sigidi in forum SMALL TIMBER MILLINGReplies: 44Last Post: 7th October 2011, 10:12 PM -

CTC Tooling

By krisfarm in forum METALWORK FORUMReplies: 9Last Post: 27th March 2010, 10:53 PM -

Lathe Tooling

By glock40sw in forum METALWORK FORUMReplies: 10Last Post: 13th August 2007, 08:39 AM -

Need tooling for mill

By antoni in forum METALWORK FORUMReplies: 3Last Post: 29th July 2007, 10:11 PM -

HSS/carbide tooling

By metaboman in forum METALWORK FORUMReplies: 1Last Post: 11th April 2007, 05:04 PM