Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 26 of 26

Thread: Another VSD Question !

-

16th December 2008, 04:30 AM #16

Home Hobbist

Home Hobbist

- Join Date

- Aug 2008

- Location

- Oatley NSW

- Age

- 69

- Posts

- 244

Hi Plushy,

Like the others have said the AEI Motor is not suitable to be used with a VFD.

You may want to get a 5.5 kW Motor that has a Delta Windings 415V and has 6 Wires coming to the Motor Terminals.

You can then buy a VFD that has Sensor Less Vector Control, they came in 5.5 kW 24 Amps Rated Output 200-240V 1/3 Phase Input, NHP has a SINUS Micro VFD in that configeration. This way you can set it up for your single phase that you have at the moment and if you move can convert it to the three phase at the new place. VFD units like this are expensive though so you need to take this into consideration as well as the cost of the new motor and you would need to have at least 15 Amp supply going to the VFD. There also would be the need to change the control for the VFD and there could be associated cost for parts to do this as well. As for the Coolant Pump you could look at changing it to a 240V Pump.

Regards,

Keith.

-

16th December 2008 04:30 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

16th December 2008, 02:32 PM #17

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

I suggest a 3hp single phase motor...Probably about $500 by the time you buy the necessary switch gear along with the motor...(which would be more then you paid for the lathe)

-

16th December 2008, 03:18 PM #18

-

16th December 2008, 04:34 PM #19

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

A 5.5kW motor is 7.5hp, the original is only 5hp or 4kW

-

17th December 2008, 04:50 AM #20

Home Hobbist

Home Hobbist

- Join Date

- Aug 2008

- Location

- Oatley NSW

- Age

- 69

- Posts

- 244

Hi RC & Chrisp,

Yes the kW would be 4kW.

As for the Motor I didnt say Star/Delta which I suppose I should have,as the connection would be made in Delta from the VFD.

Regards,

Keith.

-

17th December 2008, 03:47 PM #21

Member

Member

- Join Date

- May 2007

- Location

- Ballarat,victoria

- Posts

- 82

Thanks for all the info guys .

So i need a 415v 3 phase motor with star windings that i can change to delta 240v and a VSD that has Sensor less vector control and that should work ?

cheers Plushy

-

17th December 2008, 06:50 PM #22

Yes, you've got it. If you want I have a brand new in box never installed 2.2 kW 240v delta three phase motor here that I want to sell. If you don't need 3.7 kw this could be a good solution for you-cheaper vfd and smaller single phase circuit required. I'm also keen to learn more about that transformer.

(Be aware that you'll need a hefty circuit for 5 hp from single phase. One manufacturer recommends a 40A circuit...I'll find a link for your information.

Greg

-

18th December 2008, 08:05 AM #23

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2007

- Location

- Sydney

- Posts

- 2,340

I had a smaller star configured motor I rewired to delta and fitted with a VFD on my lathe. Despite the cries of gloom, doom, fire and brimstone that would apparently be bestowed upon me it's working just fine

In my case the conversion was simply a matter of picking out the star point, to have the job done would have cost 50 bucks. The whole project was cheaper than throwing out the old motor and replacing with a single phase equivalent. Having said that, my background was "electrickery" so maybe what I take for granted may not be appropriate for everybody.

However the real beauty of running a VFD isn't so much the phase conversion, it's the features the device provides. Soft start and soft stop being 2 big ones in my book, but mostly the fact that I have never changed mechanical speeds on the lathe, just dial in the speed on the VFD. Indeed from now on, if I have an option, I will be running 3 phase/VFD on any future purchases.

The only negative in my mind is the high pitched "whine" the motor makes since it is being fed with high frequency square waves from the VFD. I'm used to it now I guess, but at first was VERY annoying. I also have to remember to turn the lathe off at the power point since the VFD is in "standby" whenever power is applied to it. Other than that I'd say if your motor isn't suitable go get another 3 phase motor and the VFD, once it's up and running you won't regret it.

-

20th December 2008, 08:34 PM #24

Member

Member

- Join Date

- May 2007

- Location

- Ballarat,victoria

- Posts

- 82

Thanks for the info Pete good to hear from some one else who has done thsi .

Greg i have sent you a pm with the transformer owners details , he still has it and still wants to sell it .

I will keep that 2.2 kw motor in mind . I have recieved the Ward 3DS manuals i ordered from the UK and the motor is two speed according to the manual . Ward 3DS`s came out with Single speed 6 gears setup and two speed 12 Gear setup mine is apparently 2 speed 12 gears . Is it possible to get a 2 speed motor that can be wired delta 240v 3 phase and still run off a VSD ?

cheers Plushy

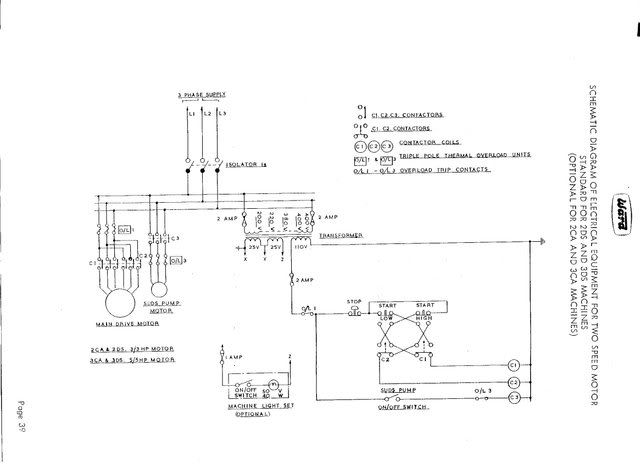

i will post up the wiring diagrams here incase any one else has a WARD lathe .

-

21st December 2008, 08:07 PM #25

Hello again..

As I understand it a VFD really must be optimised for one motor (or two identical motors). The second speed is another set of windings, and it has it's own characteristics. Not to say that there might not be a VFD out there somewhere that has that capability, but it's really a parameters programming problem...easily solved with enough memory and enough connection terminals.

But, it doesn't matter because the VFD will itself give you a huge range of speeds that will exceed what was available with the factory two speed motor. Modern vector drives claim to provide full torque* down to 10% of data plate speed, and you can safely run the motor at greater than 50 Hz as well...(since most motor designs come in two, four or six pole versions with the same internals and bearings.)

*torque however is not power as we need it. Horsepower is in fact measured by torque X rpm, so although modern VFD's provide constant torque, you still do lose the power to take big chips at low rpm. I'm not sure that this is a problem in anything less than a production setting where large diameter pieces are turned and there is an obvious need for efficiency.

At least your lathe has the gearing to allow you to select a low ratio for low speed turning. Of course gearing (or belt speed reduction drives) are a power multiplier, allowing faster motor speed for a given spindle rpm.

My own lathe project has only a back gear...an a single speed pulley on the spindle. In order to replace the obsolete AC commutator motor and defunct drive I opted for a brushless AC servo motor. Otherwise I would have needed a large (5kW +) induction motor and VFD. Oh well, at least the drive was troublesome enough that the lathe has low miles even for a 1965 model and hence worth the effort to restore.

Please keep us informed of your progress with the Ward...

Best,

Greg

-

30th December 2008, 11:16 PM #26

Member

Member

- Join Date

- May 2007

- Location

- Ballarat,victoria

- Posts

- 82

Sorry for the Slow reply .

Here is the Wiring Diagram for a Ward Lathe with 2 speed motor :

I have managed to find a local supplier who has given me a good deal on a Danfoss VSD that will run a 240v 3 phase delta 5hp motor and a motor to suit all for the princely sum of $1300 about 400 cheaper than anywhere else local a bit more than i wanted to pay but figured i shouldnt scrimp on the heart of the lathe . I should have them late next week then i just gotta work out what goes where with the electrickery .

The Shed has 2 phase and 100 amps available so i should be able to give the VSD and motor all the power it wants .

anyone wanna earn a slab and come wire it in ?

cheers Plushy

Similar Threads

-

A Question

By ubeaut in forum DOORS, WINDOWS, ARCHITRAVES & SKIRTS ETCReplies: 0Last Post: 16th November 2008, 07:21 AM -

Dumb question alert:- Salt and pepper question again

By lubbing5cherubs in forum WOODTURNING - GENERALReplies: 12Last Post: 22nd June 2008, 08:44 PM -

I have a question

By SAISAY in forum WOODWORK - GENERALReplies: 16Last Post: 6th April 2008, 01:16 AM -

FTP question.

By ozwinner in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 4Last Post: 10th March 2007, 05:07 PM -

An ROS question sander question for the box makers here

By molarman in forum BOX MAKINGReplies: 13Last Post: 20th February 2007, 02:07 PM