Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 11 of 11

Thread: Darn blanks

-

5th June 2012, 12:24 AM #1

Old Fart (my step daughters named me)

Old Fart (my step daughters named me)

- Join Date

- Sep 2010

- Location

- Mallala S.A.

- Age

- 76

- Posts

- 1,455

Darn blanks

Darn blanks

I bought a batch of special colour acrylic blanks and am having all sorts of troubles drilling them.

Even with new drills and taking my time several are cracking.

Even with new drills and taking my time several are cracking. Is there something I am doing that is wrong.

Is there something I am doing that is wrong. I counted the amount of times the drill is lowered and raised, it is approx 35 per blanks, so I am not rushing or placing pressure on the drill.

I counted the amount of times the drill is lowered and raised, it is approx 35 per blanks, so I am not rushing or placing pressure on the drill. All my blanks are held in a special blank vice and are central. As these blanks are for slimlines it is really driving me made and my temper is about to go through the roof.

All my blanks are held in a special blank vice and are central. As these blanks are for slimlines it is really driving me made and my temper is about to go through the roof. What ones I have turned have made a hell of a mess allso.

What ones I have turned have made a hell of a mess allso. Please some advice is needed.

Please some advice is needed.

Thanks

Cookie

-

5th June 2012 12:24 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

5th June 2012, 12:57 AM #2

my 2 bobs worth is stick to wood. Other than that I can't help you Cookie. Anyone can buy plastic pens. And before the howls of outrage yes I have made pens with acrylic but not anymore...too messy and tempremental for me.

PeteWhat this country needs are more unemployed politicians.

Edward Langley, Artist (1928-1995)

-

5th June 2012, 01:04 AM #3

When I drill plastic I keep a spray bottle of water and spray the hole each time I lift the bit to keep the blank cool. It does not take long to over heat.

Chris B.

Klein, TX USA

-

5th June 2012, 04:12 AM #4

Haven't heard of that trick before Chris, but it sounds logical to me !. Some Acrylic castings are just plain brittle, and will crack no matter what you do. I have had the occasional one crack around the bottom end when drilling. So fine that you don't notice it until you have almost finished turning it, and it just blows out or a chunk will fly off into the sunset

I never forget anything I remember !!

I never forget anything I remember !!

-

5th June 2012, 05:04 AM #5

What sort of shavings are you getting curly continuous ones or broken and powdery ,Also use a little water ,it may be a little bit messy but much better than broken blanks. Heat is a killer with acrylics so check your drill speed is not too fast,also standard high speed drills seem better than than the "special" ones they sell for wood , sort of flat bottomed with a small point, I forget the name of them ,but I find them useless.I assume you are drilling the blanks after cutting to length ,eg slims a touch over 50 mm from memory ,you should be able to cut at least 5mm depth each time and will get you through a blank in 10 clearances , so slow your drill a bit and lubricate to reduce friction and help cooling . If that is still a problem you may have got a really crook lot of blanks ,too much or not enough activater in the original mix can make blanks a bit soft or very brittle , I suspect that with so much problem drilling them , turning might also be a challenge , I hope not

good luck with them , cheers ~ JohnG'day all !Enjoy your stay !!!

-

5th June 2012, 09:35 AM #6

Seems most have answered what I wuld have one other problem is you maybe over tightening the vice acrylic heats up when drilling and the wall thickness becomes thin with removal of material. Acrylic then will distort more so if your vice is corner to corner.

I agree with John Brad point drill should not be used with acryic normal drill bits slow speed and steady as she goes.

slow speed and steady as she goes.

-

5th June 2012, 10:06 AM #7

Keep a squeeze bottle full of water handy when drilling, hose that bugger down as soon as you start and keep it wet and cool the whole time, just flood the hole, wont hurt a thing...other trick is to CA a thin piece of MDF or wood scrap on the bottom end where the drill will come out, keeps the blow out from happening...you can zip it off with your band saw or table saw when done.

Skip the brad point drill as was suggested, normal twist drills are fine with the scrap wood trick.

Without seeing photos of the end result when you have problems turning, I can't really offer any comment other than keep the tools as sharp as you can.

Last trick for drilling, add a few drops of liquid dishwashing detergent to the water bottle, it will help the swarf, (the shaving from the drill) to come out more easy and help keep the bit from grabbing or snagging the blank.

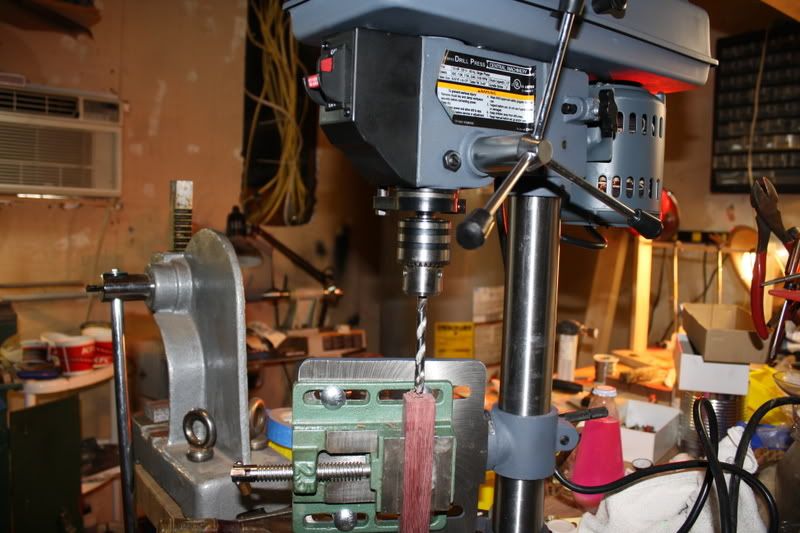

Cheap table top drill press ($69.99 American at the made in China tool store)and free vice, put an old towel under the vice and just keep the blank cool and wet...drilled well over a thousand acrylic blanks with no problems."That's why I love my computer,,,,,,,, my friends live in it."

- Colin Greg, Barnsley, South Yorkshire, England

Pen Turner Extraordinary and Accidental Philosopher.

-

5th June 2012, 10:38 PM #8

Old Fart (my step daughters named me)

Old Fart (my step daughters named me)

- Join Date

- Sep 2010

- Location

- Mallala S.A.

- Age

- 76

- Posts

- 1,455

Thanks for the advice Gents. Will give the water a go, if no good try the wood. Hey who knows might just have s*&%^y batch. Better not.

-

6th June 2012, 11:46 AM #9

As a maker of resin blanks I hate to hear of people having troubles in drilling and turning the blanks. There is some good advice here and to add my own , if your drill bit isn't sharp don't bother , it has to be able to cut. The standard metal working bit is best as it is the easiest to sharpen. Where I see people having the most problems is when there clearing the flutes of swarf and bringing the drill down a bit to quick and hitting the bottom of the hole and blowing out.

As a maker of resin blanks I hate to hear of people having troubles in drilling and turning the blanks. There is some good advice here and to add my own , if your drill bit isn't sharp don't bother , it has to be able to cut. The standard metal working bit is best as it is the easiest to sharpen. Where I see people having the most problems is when there clearing the flutes of swarf and bringing the drill down a bit to quick and hitting the bottom of the hole and blowing out.

If anyone is around the Sunshine Coast and wants to pop in to the shop, I'm more than happy to give a demo of how I do it and answer any questions. I'll even give them a blank to try on at home , gratis.

Cheers,

Bruce

Wood N Workshop

-

6th June 2012, 12:52 PM #10

GOLD MEMBER

GOLD MEMBER

- Join Date

- Aug 2007

- Location

- Brisbane

- Posts

- 1,156

The only thing I do which I haven't seen mentioned is make sure you don't drill all the way through the blank. Measure the tube length and then only drill a few mm deeper than that. Less material to remove and no chance to blow the blank as the drill exits at the end.

The other day I described to my daughter how to find something in the garage by saying "It's right near my big saw". A few minutes later she came back to ask: "Do you mean the black one, the green one, or the blue one?".

-

11th June 2012, 08:16 AM #11

New Member

New Member

- Join Date

- Jun 2012

- Location

- England

- Posts

- 9

I had similar problems but then started to drill on the lathe, you just need to fit a jacobs chuck to the tail stock. I occassionally get one wrong but its generally my fault by rushing it.

Similar Threads

-

Darn it Amos...

By edblysard in forum WOODTURNING - PEN TURNINGReplies: 14Last Post: 27th March 2012, 05:24 AM -

the shed rises, darn slowly

By hughie in forum WOODTURNING - GENERALReplies: 42Last Post: 26th April 2011, 11:13 PM -

Gosh Darn Accurate Drill Bits!

By funkychicken in forum WOODTURNING - PEN TURNINGReplies: 4Last Post: 7th July 2008, 05:18 PM -

Darn - where'd I...

By Rob Lee in forum HAND TOOLS - UNPOWEREDReplies: 21Last Post: 27th April 2005, 09:20 PM

Reply With Quote

Reply With Quote