Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 17

Thread: Drlling Blanks

-

17th August 2012, 10:34 PM #1

Drlling Blanks

Drlling Blanks

Hi all I need a little help.

How do you drill the centre out of varying sized blank. Most of my blanks are cut out of offcuts from my bigger projects. I try to get them square 20x20, 15x15 but its not always possible. Does anyone have any tips or tricks that can help me. The drills I use are the german made colt series.

Cheers Skewturn

-

17th August 2012 10:34 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

17th August 2012, 10:44 PM #2

hi skewturn

i use a pen drilling chuck bought from mcjings

heres a link to a thread not long ago with plenty of advice https://www.woodworkforums.com/f69/on...stions-149315/

hope that helps

-

18th August 2012, 08:08 AM #3

My drilling routine changes with different blanks and the degree of accuracy I need.

Generally I just drill on my drill press with a vice to hold the blank, if the blank is big enough to allow for a mm or 2 leeway.

If I need a bit better accuracy I drill on my woodlathe, I just hold the blank in my Nova chuck with pinjaws fitted, the blank needs to be pretty square for this.

If I need supreme accuracy I drill the blank on my metal lathe. Just recently, I drilled a 16mm square blank for a pen cap that had a 15mm finished size, just made it. I think it was a Jr Majestic.

It really helps if your blanks are exactly square, otherwise clamping them can be a bit iffy. I usually square mine up on the tablesaw if they are a bit out. Just pick your smallest edge, and cut the others the same.

-

18th August 2012, 08:17 AM #4

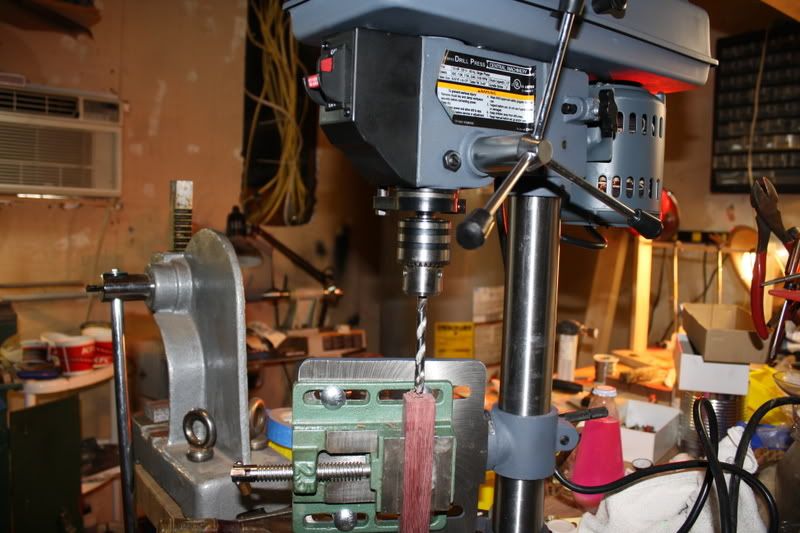

The vice can slide forward or rear ward, the table can tilt, and swing side to side so any size stock with at least on smooth side can be drilled.

For drilling deeper than the quill length, simply dill to the max depth, then retract the bit and move the stock up in the vice.

Whole rig, drill press and vice cost $69.00 to $79.00 American at the made in china store."That's why I love my computer,,,,,,,, my friends live in it."

- Colin Greg, Barnsley, South Yorkshire, England

Pen Turner Extraordinary and Accidental Philosopher.

-

18th August 2012, 12:12 PM #5

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Aug 2008

- Location

- Mooloolaba, Qld

- Posts

- 128

G'day Skewturn,

All my pen blanks are drilled using a Jacob's chuck in the lathe. Irregular blanks are fairly easy to center by eye.

Regards,

BruceLast edited by crow400; 18th August 2012 at 12:13 PM. Reason: Typo

-

18th August 2012, 01:29 PM #6

For irregular sized blanks I use the the lathe with a chuck, it centres the irregularities. Seems to work for me

-

18th August 2012, 09:39 PM #7

Thanks for all the different ideas, I look forward to giving them ago and not blowing a heap more blanks. Thanks for the pics to it is always easier to see examples.

Cheers SkewturnLast edited by Skewturn; 18th August 2012 at 09:58 PM. Reason: add on

-

19th August 2012, 08:42 AM #8

Skew you could try rounding your blanks in the lathe then drilling them. I round nearly all of my blanks before cutting to size and drilling them. That way I get a bit of a look at how the timber will look on the kit prior to glue up.

Cheers Rumnut

-

19th August 2012, 08:56 PM #9

-

20th August 2012, 05:47 AM #10

2 things apply to correct drilling ,the end must be square to the drill when you clamp it either in a chuck or vice , and the drill must be properly sharpened to cut without excessive pressure . I find standard engineering drills to be better than the brad drills in most cases

when starting the drill off just touch lightly and back off then repeat a few times till the drill has found centre and is just fully entering the material, that way it will have its natural centre and will follow straight some materials can cause a drill to wander off centre as you drill ,variations in texture and hardness etc ,drills can bend and once its in the hole you don't see it till it comes out where you were not expecting it to

when starting the drill off just touch lightly and back off then repeat a few times till the drill has found centre and is just fully entering the material, that way it will have its natural centre and will follow straight some materials can cause a drill to wander off centre as you drill ,variations in texture and hardness etc ,drills can bend and once its in the hole you don't see it till it comes out where you were not expecting it to  Making pens is deceptively simple hehe, so much to learn and its ongoing and so many paths to explore ,never boring and almost always rewarding

Making pens is deceptively simple hehe, so much to learn and its ongoing and so many paths to explore ,never boring and almost always rewarding  cheers ~ John

G'day all !Enjoy your stay !!!

cheers ~ John

G'day all !Enjoy your stay !!!

-

20th August 2012, 10:41 PM #11

-

21st August 2012, 08:56 AM #12

Skew sometimes starting the hole with a centre drill will help

Cheers Rumnut

-

21st August 2012, 09:26 AM #13

Drilling, drills, My own solution is using a drill press with a vice that has X Y adjustable axis.

My supplier of all things drilling notified me recently De Walt have brought back their

Extreme 2 drill point drills, no probs so far for me I bought up all their stock when they stopped quite a while back.

The numbers on the drill pack for 7 mm are DeWalt Extreme 2 HSS-G 7mm DIN 338.

They have a full drill point, shallow lands sharp as long life cheap as quality, do not drift, I have rarely any break out to the fact of cutting near to finished lengths of blank, I use no material under the blank, only use one fast speed ever, often drill up to a hundred blanks at a time get up to hundresd of blanks throw away the bit. Regard these bits as the cheapest part of pen making.

If you trawl back through my posts several times I have pics of my set up using 4 inch jaws in the vice with horizontal and vertical V cuts that enable even ugly cut blanks to be held quickly ,accurately invariably I cut blanks for grain almost always across the grain.

Recently I transferred all my pics to a thumb drive the headings are so numerous in an effort to start again writing in a book each photo session with more detail for reuse.

Have success. Peter.

Nil Desperandum

Nil Desperandum

-

21st August 2012, 09:50 AM #14

On the 9th of July this year I posted some pics re vice etc and facing blanks.

Kind regards Peter.

https://www.woodworkforums.com/f69/br...ml#post1516965Last edited by Big Shed; 21st August 2012 at 10:12 AM. Reason: Added link

Nil Desperandum

-

21st August 2012, 09:11 PM #15

Similar Threads

-

Drlling into round posts

By misplaced in forum METALWORK FORUMReplies: 8Last Post: 13th March 2010, 10:48 AM -

my acrylic blanks for your timber blanks

By Reece in forum SWAP, BARTER, SUPPORT A WORTHY CAUSEReplies: 3Last Post: 27th February 2010, 10:50 AM

Likes:

Likes:

Reply With Quote

Reply With Quote