Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 15

-

18th February 2007, 05:01 PM #1

Help, please:Footings and bearers

Help, please:Footings and bearers

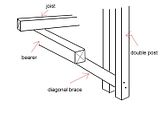

Am making a verandah at the end of a shed. I want to use hardwood bearers 75x100 mm. Hopefully, they will span 3 metres. I may need an extra support a third of the way along the bearer.

I have made some stirrup footings by welding stirrups onto some railway fishplates. I want two uprights side by side separated enough to sandwich another piece of 75x100 which will support the roofing rafters. My question is how deep and with what sort of concrete around the stirrups and fishplates should I fill the holes and what size should the holes be? The "made" fishplates and stirrups are below.

-

18th February 2007 05:01 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

18th February 2007, 07:04 PM #2

You know you can by those? With instructions for install?

Otherwise my idea is alway go overboard, the amount of conrete wont break your bank if you use heaps.

Tie some steel in above the bottom plate inside the concrete if you like, Rapid set will work ok. dig your hole bout 450 x450 square. Because you havnt got depth on your stirrups it really doesnt matter how deep you make it, but id extend them down further say 600 so they are really tied in,

It all depends on winds, size of dek etc....

Tie your steel in a noughts and crosses patern to maximise your bond in the concrete.If you dont play it, it's not an instrument!

-

19th February 2007, 12:15 AM #3

Michael,

what size joists are you using and what's their span? According to my tables (admittedly outdated by now, but still a good guide) a 100 x 75 bearer in green hardwood, F14 or better will only span 1800 with a spacing of 1800 (ie, 1800 span on joists). Your joist, if in green hardwood, will need to be 100 x 50 or 125 x 38 in F8 or better. 100 x 38 in F14 would also do, but I'd advise against going the 38mm wide stock as it has more tendency to tip or roll and you may need to strut or block it.

Mick"If you need a machine today and don't buy it,

tomorrow you will have paid for it and not have it."

- Henry Ford 1938

-

19th February 2007, 08:57 AM #4

Is rapid set suitable for footings? I wouldn't have thought so. I also think they need to be bigger than 450 square. I would say 500 for a single post but for a double post like that, maybe bigger.

My span tables agree with yours, Mick. A 200x75 in F7 or better will span 3 metres with 1800 spacing.

-

19th February 2007, 10:03 AM #5

-

19th February 2007, 01:32 PM #6

Apparently, if used correctly rapid set is okay for structural work. Checked a manufacturer's website a while back. Trouble is, of course, that it's a whole lot easier to get the rapid set stuff wrong than standard concrete.

Mick"If you need a machine today and don't buy it,

tomorrow you will have paid for it and not have it."

- Henry Ford 1938

-

19th February 2007, 01:38 PM #7

OK I can accept that there may be some products described as 'rapid set' which may be OK according to the manufacturer, so maybe the thing to do is to check with them before using it.

I'd still be happier with a metre of blue metal, sand, a couple of bags of cement and the trusty concrete mixer...

-

19th February 2007, 02:14 PM #8

-

19th February 2007, 07:37 PM #9

I'll play the devil

A verandah requires a building permit.

The documentation on the drawings would show the pad size determined from the area of the verandah supported.

The depth of the pad would be determined by the soil type.

The amount of bulk concrete in the hole & the depth of embedment of the stirrup would be determined from the uplift force taking into account the roof area 'tied down' and the designated wind gust speed for the site.

Hardwood bearers & joists can only be used if they are durability class 1 or 2 timber or they are protected by a roof projecting past at 30 degrees to the vertical.

Yes I Know . . . . . .Peter Clarkson

www.ausdesign.com.au

This information is intended to provide general information only.

It does not purport to be a comprehensive advice.

-

25th February 2007, 03:22 PM #10

Thanks Lads.

Thanks Lads.

Probably I have started to ask for advice too late, or later than I could have. The timber is 100 yr old stringy bark and as hard as rock. It is 100mm by 75mm. I propose supporting it after 1800 by a diagonal support connected between two uprights. I may have misled you, Mick as the joists will be cyprus pine and the bearers the old stringy.

The decking will be slats, similar to those in a shearing shed pen, 'cos it would be used for shearing once a year.

It will be covered with a corrugated gal roof, on old oregon rafters and battens.

Peter, thanks for playing the devil, may I say you do it well. I know from my architect bro in law that there are all kinds of regulations. Were you to know of the local gov people in this shire you would not put your worst enemy near them.

Thanks all.

-

25th February 2007, 06:08 PM #11

-

26th February 2007, 12:41 AM #12

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

-

28th February 2007, 11:12 AM #13

-

1st March 2007, 12:27 AM #14

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

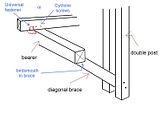

I'd be installing a Universal (multigrip) fastener, or a trip-L-grip as I've shown here, or cyclone screws skewed from the joist down, as well as one from the bearer up into the joists, to stop the bearer slipping outwards as the timber ages. You'd also need a birdsmouth in the brace to stop the bearer rolling.

Cheers

-

2nd March 2007, 10:42 AM #15

Thanks.

Thanks.

Thanks Pawnhead, I never cease to be amazed at the skill and generosity of people like you and JMMick out there assisting guys like me in the bush who only know half of most things, and usually do very amateur jobs.

Michael

not quite sure what you mean by this, care to elaborate?

not quite sure what you mean by this, care to elaborate?